Automated Garment Assembly in 2025

In 2025, automated garment assembly moves from labs to its first commercial deployments. This progress in apparel automation results from the integration of advanced robotics.

Artificial intelligence is the core driver. This AI helps robots and cobots perform complex assembly. Artificial intelligence guides the automation, while further artificial intelligence improves the entire assembly process.

Initial fully robotic garment assembly will focus on simpler production, demonstrating the future of robotics.

Key Enabling Technologies

The shift toward automated garment assembly is not a single breakthrough. It is the result of several key technologies maturing at the same time. These advancements in artificial intelligence, robotics, and system integration are creating the foundation for the factories of tomorrow.

AI, Vision, and Continuous Learning

Artificial intelligence is the brain behind modern apparel automation. Advanced vision systems, powered by artificial intelligence, allow machines to see and understand different fabric types, textures, and orientations. This capability is crucial for handling the unpredictable nature of textiles.

A key development is continuous learning. Artificial intelligence enables robots and cobots to improve their performance over time without needing constant reprogramming. This process uses reinforcement learning methods, like Q-Learning. A robot learns from its actions through trial and error. It receives feedback on its performance, allowing it to discover the most efficient way to complete a task. This approach helps the robot learn the best assembly sequence over 98% of the time, improving precision with every repetition.

This makes the entire production process data-driven and highly adaptable. Data-driven assembly lines use artificial intelligence for more than just assembly.

- Predictive Maintenance: Artificial intelligence analyzes sensor data from machinery to predict failures before they happen. This prevents costly downtime.

- Waste Reduction: AI algorithms optimize fabric-cutting patterns. Systems can increase material use by up to 10%, reducing waste significantly.

- Assembly Line Optimization: Intelligent automation uses real-time data to adjust production, minimize downtime, and ensure consistent quality.

Advanced Robotic Manipulation

Working with soft, pliable fabrics has always been a major challenge for automation. Unlike rigid materials like metal or plastic, fabric stretches, folds, and slips. Recent progress in robotics directly addresses this issue.

New end-effectors, or grippers, give robots the delicate touch needed for textiles. Innovations include:

- Vacuum Grippers: These use principles like Bernoulli or Venturi to gently lift and move fabric pieces without causing damage.

- Electro-adhesion (EA): This technology allows a gripper to make fabric "stick" to its surface on demand, providing secure, one-sided handling.

- Biomimetic Soft Grippers: Inspired by nature, these grippers use soft materials to handle delicate fabrics with human-like dexterity.

Beyond handling, new joining methods are replacing traditional sewing. Pixel bonding technology, a form of microadhesive application, is a leading alternative.

A Stitch in Time? Not Anymore. Pixel bonding uses a digital adhesive to create seams less than 1mm wide. This process is reportedly 20 times faster than manual sewing and offers double the precision. The bonds enhance garment stretch and durability. Crucially, the adhesive can be reversed, allowing materials to separate cleanly for easier recycling—a task nearly impossible with sewn seams.

These advancements in robotics allow robots and cobots to pick, place, and join fabric pieces with the speed and consistency required for commercial production.

Next-Generation Integrated Systems

The true power of these technologies emerges through integration. Companies are now building complete, end-to-end systems that combine vision, robotics, and advanced joining methods into a single, cohesive platform. These platforms represent the first wave of true automated garment assembly.

A prime example is CreateMe's Modular Robotic Assembly (MeRA) platform.

| Feature | Capability |

|---|---|

| Technology | Integrates robotics, modular hardware, and AI software. |

| Joining Method | Uses Pixel digital microadhesive instead of thread. |

| Throughput | Produces up to 1 million T-shirts per machine annually. |

| Speed & Precision | Claims to be 20x faster than sewing with 2x the precision. |

This type of modular integration allows for local, on-demand manufacturing. It cuts lead times from months to days and makes small-batch production economically viable.

Organizations are also fostering this ecosystem. The Advanced Robotics for Manufacturing (ARM) Institute funds critical projects that accelerate innovation. These initiatives bring together technology companies, universities, and apparel manufacturers to solve specific challenges. Funded projects include:

- Automated T-Shirt Assembly System

- Robotic Bottom Hemming

- Robotic Fabric Fusing Operations

- End-to-end assembly of PPE

These collaborative efforts are essential for creating the standardized tools and processes needed for widespread adoption of automation in the apparel industry. The integration of hardware and software is turning the concept of a fully automated factory into a commercial reality.

Impact of Automated Garment Assembly

The integration of artificial intelligence and advanced robotics is creating tangible impacts. These technologies are not just theoretical concepts. They are actively reshaping production lines, supply chains, and the workforce. The move toward automated garment assembly creates new commercial opportunities and redefines the economics of apparel manufacturing.

Leading Commercial Use Cases

Initial commercial applications of apparel automation focus on products with simpler construction and high demand. Personal Protective Equipment (PPE) became a primary testing ground. The COVID-19 pandemic created an urgent need for domestic PPE production. This accelerated the adoption of robotics.

- Siemens Corporation

- Henderson Sewing Machine Corporation

- Sewbo Inc

- Bluewater Defense

- Industrial Sewing and Innovation Center (ISAIC)

These organizations, among others, pioneered automated systems for PPE. For example, Harbour Technologies built a robotic cell to produce FDA-approved isolation gowns. SDC Automation also helped manufacturers scale PPE production efficiently.

Beyond PPE, automation is excelling in specific, repetitive tasks. Hemming and fabric rolling are two key areas with growing adoption.

- Apparel and Home Textiles: Automated hemming machines finish items like jeans, dresses, and curtains. This ensures consistent quality and faster production.

- Fabric Preparation: Fabric rolling machines prepare materials for cutting and sewing. This step minimizes downtime and ensures uniformity.

- Fast Fashion: E-commerce brands use automated hemming to meet rapid delivery timelines. High-speed machines reduce lead times and lower labor costs.

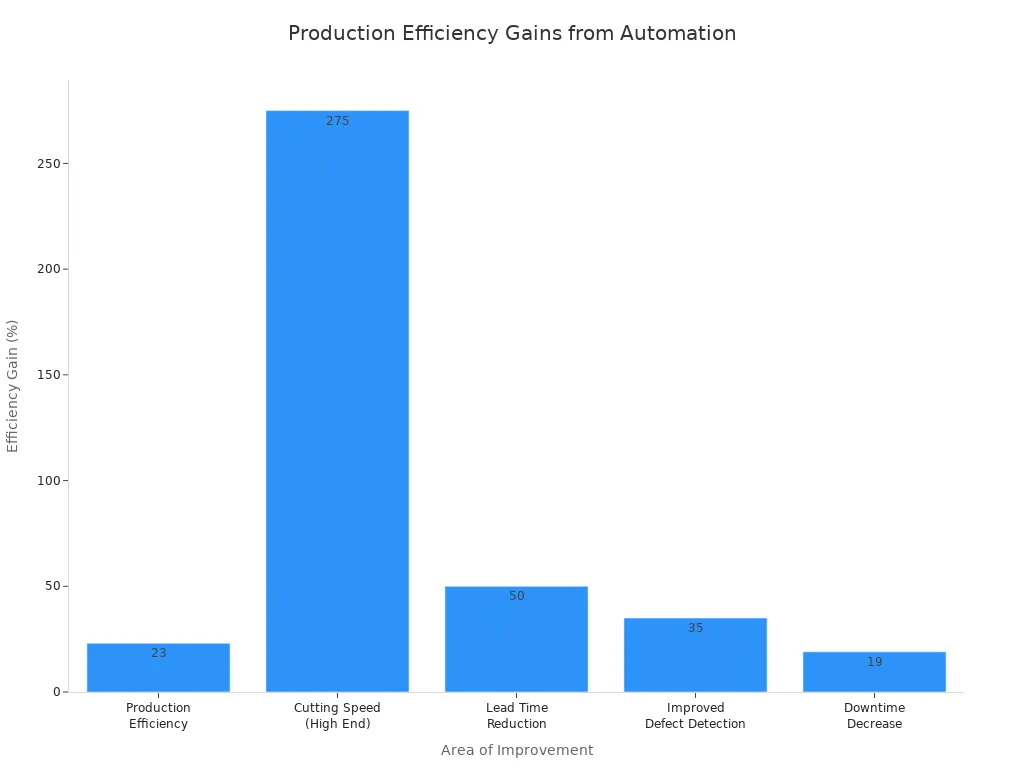

These early applications deliver significant efficiency gains. Data shows automation boosts productivity across the board. An AI-powered system can find 35% more defects than human inspectors. A Sewbot can complete a T-shirt assembly in just 22 seconds. These improvements make a compelling case for investment.

The Business Case for Reshoring

For decades, high labor costs pushed apparel manufacturing overseas. Automation changes this economic equation. Robots and cobots make it possible to bring production back to the US and Europe. This is known as reshoring. Automated systems directly address the main challenges of domestic manufacturing.

| Reshoring Challenge | Automation Advantage |

|---|---|

| High Labor Costs | Reduces reliance on manual labor, minimizing wage expenses. |

| Supply Chain Disruptions | Enables local production, shortening lead times and transport costs. |

| Quality Control | Improves inventory management and order accuracy, reducing errors. |

| Sustainability Goals | Lowers carbon footprint by reducing long-distance shipping. |

| Scalability | Allows manufacturers to adapt quickly to changing market demands. |

Several brands are already embracing this model. Companies like New Balance and Carhartt maintain a strong domestic manufacturing presence. They use advanced technologies to stay competitive. This strategy shortens the supply chain significantly. Proximity-based sourcing reduces transportation emissions and delivery times. Smart manufacturing, powered by artificial intelligence and the Internet of Things (IoT), optimizes the entire production process. This makes the supply chain more resilient and responsive.

Evolution of the Workforce

Automation is transforming jobs, not just eliminating them. The decline of roles like sewing machine operators is part of a long-term trend. This trend started long before modern artificial intelligence. While some manual jobs will be displaced, many new, higher-skilled positions are emerging. Projections show a net gain of 78 million roles globally by 2030.

The factory of the future needs a new kind of worker. Expertise will shift from manual dexterity to technical oversight.

New roles require skills in robotics, data analysis, and system maintenance.

- Robot Wrangler: This technician troubleshoots and maintains the robots and cobots on the factory floor.

- AI Systems Integrator: This specialist connects different AI tools and IoT sensors to ensure the smart factory runs smoothly.

- Industrial Maintenance Technician: This professional uses AI-driven data to perform predictive maintenance on machinery.

This transition requires a major focus on workforce development. Companies and educational institutions must create training programs to upskill current employees. H&M, for instance, partners with technology firms to retrain its staff for automated environments. Organizations like Shimmy Technologies offer digital training to prepare apparel workers for the jobs of the future. These reskilling initiatives are essential. They empower workers to move from manual tasks to higher-value technical roles, ensuring a just transition in the age of automation.

The Road Ahead

The path to widespread adoption of automated garment assembly involves overcoming two major hurdles. Manufacturers must achieve cost and speed parity with traditional methods. They also need deep collaboration across the industry to standardize the technology.

Reaching Cost and Speed Parity

Achieving cost and speed parity is the primary goal for apparel automation. For certain tasks, modern systems are already competitive. Platforms like CreateMe's MeRA are described as cost-competitive with offshore manufacturing. They can produce items up to 20 times faster than manual sewing. This progress shows that parity is within reach for simpler garment assembly.

However, significant challenges remain for more complex apparel. Current robotics struggles with the inherent nature of textiles.

- Fabric Limpness: The low stiffness of fabric makes it difficult for robots to handle, unlike rigid parts in other industries.

- Complex Operations: Tasks like sewing curves and darts require a level of dexterity that current technology finds hard to replicate.

- Gripper Limitations: Traditional robotic grippers are not designed for soft materials, requiring new, specialized end-effectors.

Overcoming these issues with advanced artificial intelligence is key to matching the speed of a human worker for every type of garment.

The Importance of Collaboration

No single company can solve these complex challenges alone. Progress depends on strong partnerships between industry, government, and academia. Organizations like the Advanced Robotics for Manufacturing (ARM) Institute play a vital role. The ARM Institute uses government funding to support projects that advance the use of robotics and artificial intelligence in manufacturing. Academic institutions like Manchester Metropolitan University also lead research, helping small businesses adopt new technologies.

A key outcome of this teamwork is the development of interoperability standards. These standards allow robots, cobots, and AI software from different vendors to communicate seamlessly.

Groups like MassRobotics and the ARM Institute are creating common rules for data sharing. This work ensures that a factory's systems can work together efficiently. This collaborative effort on artificial intelligence and hardware integration is building a flexible and scalable foundation for the future of apparel assembly.

In 2025, automated garment assembly is no longer a concept but a commercial reality. Maturing technologies, powered by AI, are enabling the first applications that reshape apparel manufacturing. This automation fosters a more agile ecosystem, makes reshoring economically viable, and creates new, higher-skilled jobs. The industry is building a future that is more responsive, local, and sustainable.

FAQ

What drives apparel automation?

Three key technologies enable automated garment assembly. Their convergence makes modern automation possible.

- Advanced robotics for material handling

- AI-powered vision for fabric recognition

- Innovative joining methods like pixel bonding

Will robots replace all sewing jobs?

Automation transforms the workforce instead of eliminating it. It creates new, higher-skilled roles.

The industry sees a shift from manual labor to technical jobs. Workers will manage robotic systems, analyze data, and perform specialized maintenance, leading to a net gain in roles.

What garments are automated first?

Initial automation focuses on products with simpler designs and high production volumes. This allows companies to prove the technology's value before tackling more complex apparel.

| Product Category | Examples |

|---|---|

| Simple Apparel | T-shirts, leggings |

| Protective Gear | PPE gowns, masks |

| Repetitive Tasks | Hemming, fabric rolling |

Is automation faster than a human?

For specific tasks, yes. ⚡️ An automated system can assemble a T-shirt in just 22 seconds. However, human workers remain faster for complex operations like sewing curves. Reaching speed parity across all garment types is a primary goal for the industry.

See Also

Revolutionizing Textile Manufacturing: AI-Driven Predictive Maintenance Strategies for 2025

Transforming Fashion Logistics: AI Sensor Technology's Influence on Supply Chains by 2025

Achieving Peak Efficiency: AI-Powered Just-In-Time Delivery Systems for 2025

Optimizing Fashion Retail: AI-Driven Dynamic Safety Stock Solutions for 2025

Boosting Warehouse Operations: Cutting-Edge Technologies Enhancing Productivity by 2025