2025 Warehouse Trends Computer Vision Tech

Computer vision is a key driver for warehouse automation. The technology enables automated data capture for superior operational efficiency. This growth fuels advancements in warehouse automation and real-time inventory tracking.

The market for AI-powered warehouse automation is expanding rapidly. It reached nearly USD 3 billion in 2024 and shows significant upward trends.

Advanced computer vision provides accurate data that transforms warehouse management. AI and computer vision are essential for modern warehouse automation, reducing errors and improving processes in warehouse automation.

Computer Vision for Warehouse Automation

Computer vision is the engine driving the next generation of warehouse automation. This technology gives machines the ability to see and interpret their surroundings. It enables a seamless flow of operations from receiving to shipping. The integration of computer vision with robotics and AI is creating smarter, faster, and more reliable systems for warehouse management. This shift is fundamental for companies aiming to stay competitive.

Automated Receiving and Sorting

The receiving dock is often a major bottleneck in warehouse operations. Computer vision transforms this area into a model of efficiency. Systems now perform automated data capture with incredible speed and accuracy. This technology is a cornerstone of modern warehouse automation.

When packages arrive, the process is swift:

- A camera, often on a robotic arm, scans a barcode or QR code.

- The system uses Optical Character Recognition (OCR) to identify the product SKU.

- It cross-references this information with the warehouse management database to verify the item.

- Correct items proceed for sorting, while incorrect items are flagged for manual review.

Simultaneously, computer vision systems validate package dimensions. A camera captures an image of the item on a conveyor. The software then analyzes its length, width, and height. This ensures the package meets courier requirements and helps select the right packing materials later. Based on this data, robotic arms sort items into correct bins or onto designated conveyor paths, a key function for warehouse automation.

Vision-Guided Robotics (VGR)

Vision-Guided Robotics (VGR) gives industrial robots the gift of sight. This technology is a critical component of advanced warehouse automation. VGR systems use cameras and sophisticated AI software to guide robotic actions. This allows robots to handle tasks that require precision and adaptability. Key components include 3D vision for depth perception and advanced gripping technology for handling diverse items.

These robots perform a variety of tasks with high accuracy.

- Bin Picking: Robots can identify and pick specific items from bins containing randomly piled parts. This is essential for fulfilling on-demand orders.

- Palletizing and Depalletizing: VGR enables robots to stack boxes onto pallets or unload them with stability and speed. Boston Dynamics, for example, uses a machine vision solution that allows its robots to handle mixed-SKU pallets even in difficult lighting conditions. This improves efficiency and frees employees from physically demanding work.

- Assembly and Machine Tending: In warehouse automation, robots use computer vision to pick parts and place them accurately for assembly or into other machines.

The combination of computer vision and robotics makes warehouse automation more flexible and intelligent.

Optimized Packing and Shipping

Efficient packing is crucial for reducing costs and ensuring timely deliveries. Computer vision optimizes this final step of the warehouse automation process. AI algorithms analyze an item's dimensions to select the perfect-sized box. This simple step significantly reduces the use of filler materials and cuts down on waste.

During loading, computer vision systems monitor trailer and container packing. They create an optimal loading plan to maximize space. High-resolution cameras track item placement in real-time. The AI compares the actual loading against the plan and sends alerts for improper stacking or weight imbalances. This ensures load stability and safety. An electronics manufacturer saw a 15% reduction in packaging material and a 20% increase in packing speed by implementing AI packaging systems. These gains highlight the power of computer vision in warehouse automation.

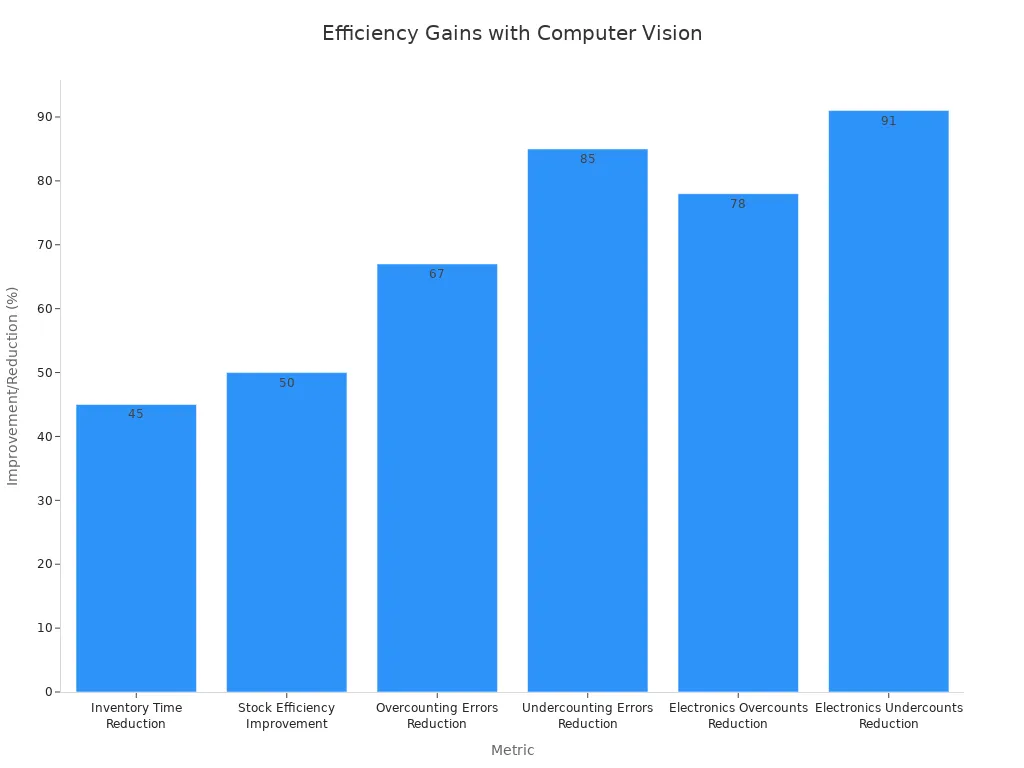

The measurable improvements are clear. Companies using computer vision in their warehouse automation workflows report dramatic reductions in errors and significant gains in efficiency.

This level of optimization was once impossible. Now, computer vision makes it a daily reality in modern logistics.

Transforming Inventory with AI-Powered Computer Vision

Manual inventory counts are becoming obsolete. AI-powered computer vision delivers a far superior solution for modern logistics. This technology provides a dynamic, continuous, and highly accurate view of stock levels. It moves beyond simple scanning to create an intelligent ecosystem for automated inventory management. The result is a system that minimizes package loss, reduces human error, and ensures precise inventory levels from receiving to shipping. This evolution in warehouse automation is critical for maintaining a competitive edge.

Drone-Based Inventory Scanning

Traditional inventory audits are slow and disruptive. They often require shutting down operations and dedicating significant labor hours. Drone-based scanning offers a revolutionary alternative. Autonomous drones navigate warehouse aisles, using advanced computer vision to capture inventory data without human intervention. These drones are equipped with sophisticated technology.

- Obstacle Sensing Systems: Full 360-degree sensors allow drones to avoid collisions with racks, equipment, and people.

- High-Resolution Cameras: Multiple cameras capture barcodes, QR codes, and text on pallets, even from a distance.

- On-Board Processing: Drones can continue to operate and collect data even with an unstable network connection.

- Smart Interface: Data is transmitted in real time to a central inventory system for analysis.

This form of warehouse automation provides incredible efficiency gains. Drones can scan hundreds of pallet positions in minutes, a task that would take humans hours. Leading companies have already seen impressive results.

| Company | Time Savings | Key Benefits |

|---|---|---|

| Walmart | Inventory checks reduced from days to hours | Continuous operation, reduced stockouts, and improved order fulfillment. |

| DHL | Over 50% reduction in stocktaking time | Workers focus on higher-value tasks, and the WMS receives real-time updates. |

| Nike | Significantly faster inventory audits | More frequent audits are possible, ensuring highly accurate records. |

The use of drones for inventory checks improves overall warehouse automation and boosts inventory accuracy to nearly 100%.

Real-Time Stock Monitoring

While drones excel at periodic cycle counts, fixed cameras provide constant oversight. This method of real-time inventory tracking uses cameras mounted on ceilings or shelves. The cameras continuously stream visual data to an AI platform. The AI analyzes the footage to monitor stock levels 24/7. This approach to computer vision helps managers:

- Monitor stock levels on every shelf.

- Identify specific products automatically.

- Detect discrepancies between system data and physical stock.

💡 Pro Tip: Walmart's Intelligent Retail Lab uses ceiling cameras and AI to flag low-stock items. This allows staff to restock shelves proactively before a customer finds an empty space.

When the AI detects a low-stock or out-of-stock event, it triggers an automated alert. These notifications can be sent through email, Slack, or in-app dashboards. In advanced systems, the AI can even generate an automated purchase order to replenish inventory. This level of warehouse automation closes the loop between detection and action. The advantages of AI-powered computer vision over traditional methods are clear.

| Feature | Barcode Tracking | AI-Powered Computer Vision |

|---|---|---|

| Automation | Requires staff to scan each item | Fully automated inventory tracking |

| Real-time Visibility | Updates inventory only when scanned | Constant real-time monitoring |

| Predictive Analytics | No forecasting capabilities | Uses AI to predict demand |

| Error Reduction | Prone to human error | AI eliminates scanning mistakes |

This technology offers a more streamlined and cost-effective operation for any modern warehouse.

Object Recognition for Unpackaged Goods

Many warehouses handle items that cannot be barcoded, such as fresh produce, bulk hardware, or irregularly shaped components. Counting these items has always been a manual, error-prone process. Computer vision solves this problem with advanced object detection and tracking. An AI model is trained on thousands of images to recognize specific items based on their unique visual characteristics like shape, size, and color.

Frameworks like TensorFlow and YOLO (You Only Look Once) power these systems. A camera captures an image of a bin or pile of goods. The computer vision software then analyzes the image to identify and count each individual item in real time. This technology is a game-changer for automated inventory management in industries like agriculture and manufacturing. While challenges like object overlap and poor lighting exist, high-quality training data helps the AI achieve remarkable precision. This application of computer vision is a key part of intelligent warehouse automation.

Key Benefits of AI in the Warehouse

Adopting AI in warehouse operations delivers tangible benefits that strengthen the entire supply chain. This technology automates repetitive tasks, provides precise data, and creates a safer work environment. The result is a more efficient, cost-effective, and competitive operation.

Reduced Labor Costs and Errors

AI significantly cuts down on operational expenses. Automating tasks like inventory counting and quality control can reduce labor costs by 10-20%. This automation also eliminates the costly human errors common in manual processes. For example, businesses using AI see a 37% decrease in inventory discrepancies. This sharp reduction in mistakes boosts overall efficiency. Delaying investment in this technology can be expensive. Some AI systems, like inventory drones, can deliver a return on investment in less than a year, making it a financially sound decision.

Enhanced Inventory Accuracy

Achieving precise inventory levels is a major advantage of AI. Manual counts are slow and often inaccurate. AI-powered systems, however, deliver exceptional precision.

Some warehouses using this technology report an inventory accuracy rate of over 99%.

This level of accuracy helps prevent stockouts and reduces overstocking. Furthermore, AI dramatically increases speed. Automated systems can count inventory up to 15 times faster than human teams. This efficiency allows for more frequent cycle counts without disrupting operations.

| Method | Accuracy | Speed |

|---|---|---|

| Manual Counting | Prone to error | Slow, labor-intensive |

| AI-Powered Counting | Over 99% accurate | Up to 15x faster |

Improved Safety and Throughput

A safer warehouse is a more productive warehouse. AI systems act as a vigilant safety monitor 24/7. They use cameras to detect potential hazards in real time.

- Blocked aisles or fire exits

- Spills that create slip risks

- Workers getting too close to moving equipment

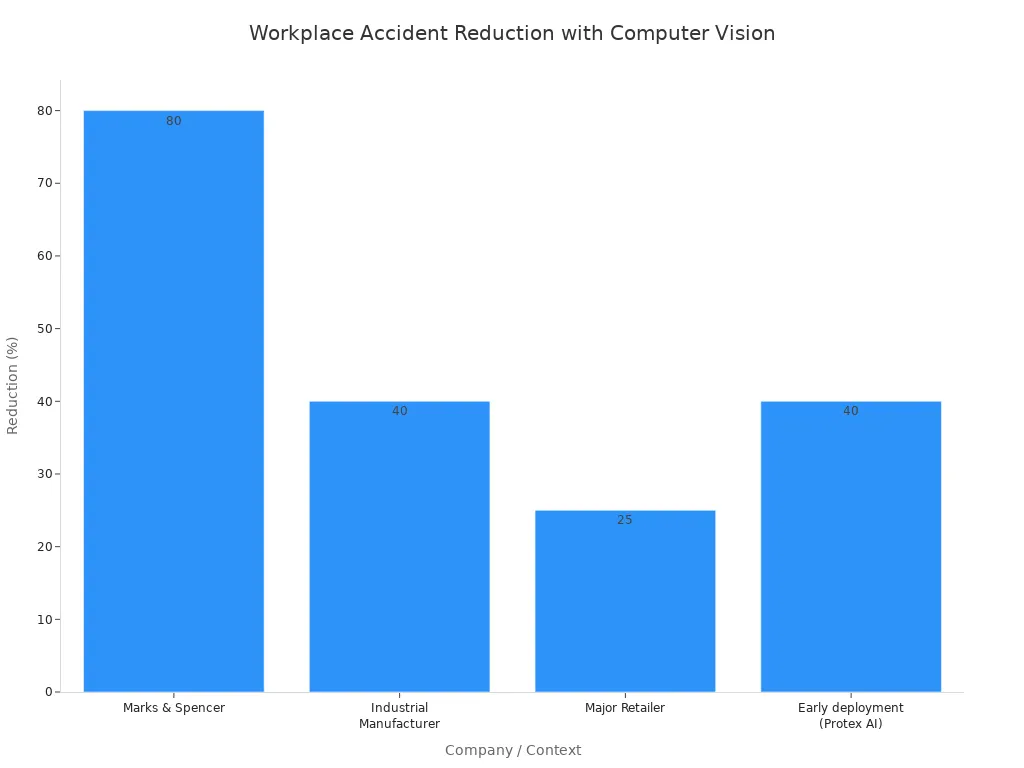

When the AI identifies a risk, it sends an immediate alert to supervisors. This proactive approach helps prevent accidents before they happen. Companies that implement AI-driven safety monitoring have seen remarkable results.

Fewer accidents mean fewer operational shutdowns, which directly leads to higher and more consistent throughput.

Computer vision is a practical 2025 trend for warehouse automation. It provides precise, real-time inventory control. This technology achieves over 98% accuracy in data extraction, transforming warehouse management. Leaders should evaluate their current processes to identify pain points. A pilot project in warehouse automation can provide a significant competitive edge. This strategic approach to warehouse automation improves warehouse management and drives efficiency. Adopting this technology is a critical step for modern warehouse automation. This move ensures superior warehouse automation and operational excellence.

FAQ

How does computer vision integrate with a WMS?

Computer vision systems connect to a Warehouse Management System (WMS) through an API. The vision system captures data, such as inventory counts or package dimensions. It then sends this information directly to the WMS. This process provides real-time updates and ensures data consistency across platforms.

What is the typical implementation timeline?

A pilot project for computer vision can take 2 to 4 months. Full-scale deployment depends on the warehouse size and complexity.

A phased rollout often works best. It allows teams to adapt to the new technology and minimize operational disruption while scaling the solution.

Can computer vision work in low-light conditions?

Yes, modern systems perform well in various lighting environments. They use high-sensitivity cameras and infrared (IR) technology to capture clear images in dim light. The AI algorithms are trained on diverse datasets. This training helps them accurately identify objects even with shadows or poor illumination.

Is computer vision expensive for small businesses?

The cost of computer vision technology has decreased. Many providers now offer scalable, subscription-based models (SaaS). This approach reduces the initial investment. It makes advanced warehouse automation more accessible for small to medium-sized businesses seeking a competitive advantage.

See Also

Cutting-Edge Innovations Revolutionizing Warehouse Efficiency and Output by 2025

Groundbreaking Intralogistics Advancements Redefining Tomorrow's Warehouse Operations and Design

Artificial Intelligence Sensors' Profound Impact on 2025 Fashion Supply Chains

AI-Powered Dynamic Safety Stock: The Ultimate 2025 Fashion Retail Solution

Pioneering Technologies Reshaping Shipping Operations and Logistics Efficiency by 2025