The Future of Generative Algorithms in Denim

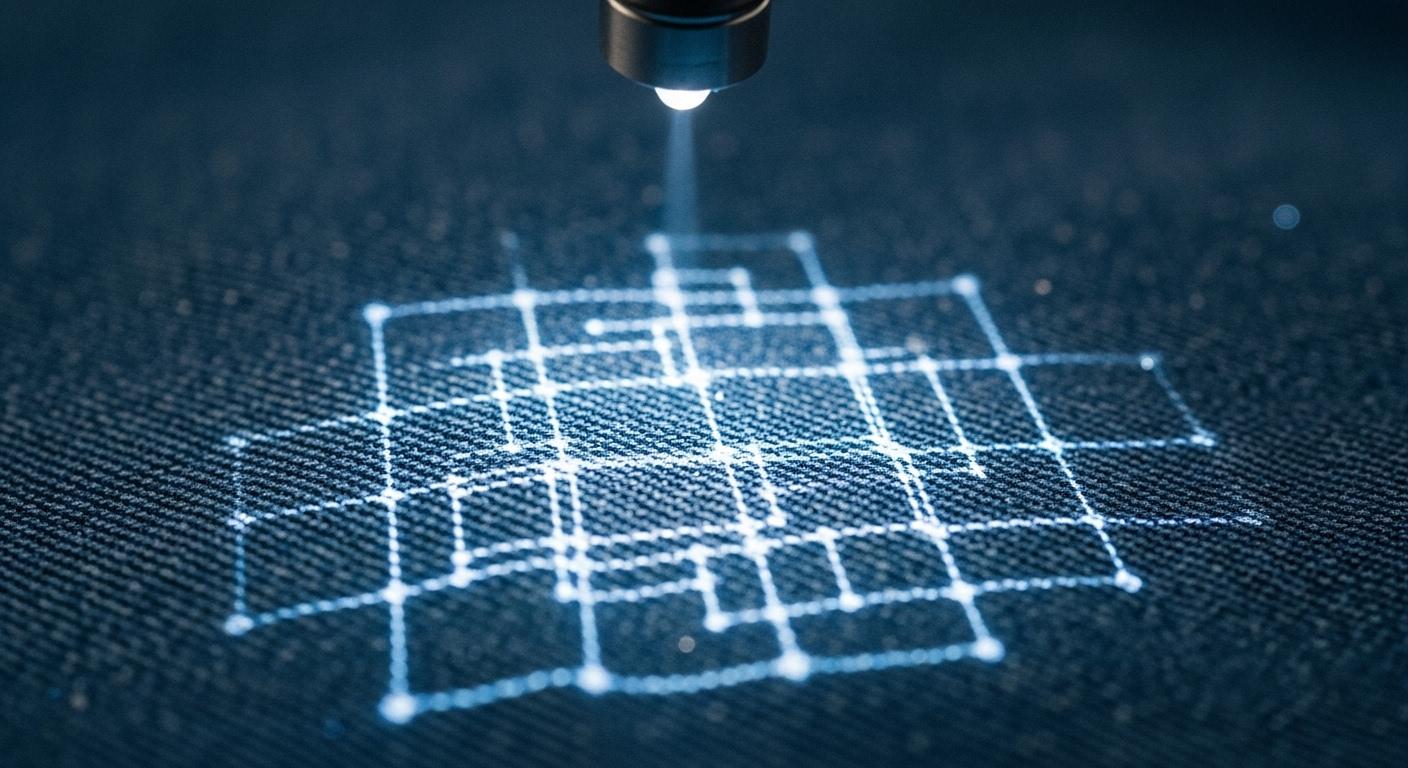

Generative algorithms are a form of artificial intelligence. These AI tools study thousands of images of denim to create a new, unique wash pattern. This digital design is then sent to laser-finishing machines. The machines precisely etch the wash onto jeans. This modern process replaces older methods.

Traditional denim production is very thirsty. A single pair of jeans can use over 3,781 liters of water.

This innovation in artificial intelligence signals a major shift in the denim industry. It changes how companies approach fashion design and finish. The technology paves the way for the future of denim, where a custom wash finish is fast, personal, and sustainable.

How Generative Algorithms Drive Design

Generative algorithms create new patterns from existing data. They are the engine behind this new wave in the design of denim. The process combines creative artificial intelligence with precise machinery. It transforms a digital idea into a physical product.

Understanding GANs

One popular method uses Generative Adversarial Networks (GANs). Think of a GAN as a team of two AIs: an artist and an art critic.

- The Generator (the artist) creates a new denim wash pattern. It tries to make the design look as real as possible.

- The Discriminator (the art critic) reviews the pattern. It compares the new design to its database of real denim images and decides if it looks authentic or fake.

This cycle repeats thousands of times. The generator gets better at making realistic patterns. The discriminator gets better at spotting fakes. The result is a completely new and unique wash design. Other methods also exist, like parametric patterns, where algorithms build a design based on mathematical rules.

Learning Denim Aesthetics

An AI must first learn what makes denim look like denim. The artificial intelligence studies huge datasets to understand the material's unique character. These datasets include:

- Historical runway collections: This data teaches the AI about evolving styles and trends.

- Retail catalogs: This information helps the AI understand what customers buy.

- Fabric and texture data: This is key for learning how a wash appears on different denim weights and textures.

Brands are already using this technology. G-Star Raw used an AI tool to create ideas for a denim couture piece. Human designers gave the AI text prompts. The artificial intelligence then generated concepts that the team brought to life.

From Pixels to Laser Patterns

The AI's final output is a digital image file, like a PNG or JPEG. This file must be converted into instructions for a laser machine. This technical process turns pixels into a precise path for the laser to follow.

- First, designers open the AI's image file in special software. They start with a high-quality image for the best results.

- Next, they clean up the image. They convert it to black and white and remove any small imperfections or "noise."

- Then, they use a tool to convert the image into a vector file. This file format uses lines and curves instead of pixels.

- Finally, they save the vector file in a format the laser machine can read, like a DXF or G-code file.

Pro Tip for Quality: To get the best laser results, designers use clean, high-contrast images. Image formats that use lossless compression, like TIFF or PNG, are better than JPEGs. A clean image ensures the laser etches the design smoothly onto the denim fabric.

Key Benefits for the Denim Industry

Generative algorithms offer major advantages for the denim industry. This technology creates new opportunities for brands and consumers. It makes the entire process of creating a denim wash finish smarter, faster, and more sustainable.

The Rise of Hyper-Personalisation

Brands can now offer on-demand personalisation at a large scale. Customers no longer just choose a size and color. They can become co-creators of their own clothing. This deep level of customization builds a stronger connection between a person and their apparel.

This new level of interaction allows customers to create a unique custom wash. They can use several methods to share their vision:

- Text Prompts: A customer can describe the desired wash, using words like "lightly faded on the thighs with a vintage look."

- Image Uploads: A person can upload an inspiration photo, like a picture of a sunset or a worn-out pair of jeans, for the artificial intelligence to interpret.

Major brands like Levi's already allow customers to personalize aspects of their denim. This trend moves fashion from mass production to mass customization.

Smarter and Faster Production

Artificial intelligence streamlines the entire production workflow. It significantly reduces the time from initial concept to finished product. AI-powered generative design tools can cut product development time by up to 30% by creating concepts much faster than human teams. Companies in other industries have seen huge gains. For example, Tesla cut its design-to-production time by nearly 50% using AI-generated designs.

This speed also leads to less waste. AI systems use predictive analytics to forecast demand more accurately. This helps brands avoid overproduction, a major source of waste in the fashion world. Better forecasting means companies make only what they can sell.

| Brand | AI Method Used | Impact on Overproduction Reduction |

|---|---|---|

| Zara | Predictive analytics | Reduced excess inventory by 30% |

| H&M | AI-powered systems | Tailors inventory to specific stores |

| Levi's | Supply chain analytics | Optimizes operations and reduces surplus fabric |

A Greener Future for Denim

Perhaps the most important benefit is sustainability. The traditional denim wash process uses huge amounts of water and harmful chemicals. AI-guided laser technology offers a much cleaner alternative.

AI-guided laser systems can reduce water consumption by up to 90% compared to traditional stone washing. This technology helps transform denim production into a more eco-friendly process.

This modern approach also eliminates dangerous substances. Technologies like Wox by Wiser Tech provide a safer finish for workers and the planet. This system replaces harsh chemicals with a clean and efficient process.

- It completely discards hazardous chemicals like potassium permanganate.

- It uses ozone, which is generated from oxygen, to create the wash effect.

- After the process, the leftover ozone is safely converted back into oxygen and water.

This innovation makes the final custom wash not only beautiful but also responsible. It marks a critical step toward a truly green fashion industry.

Current Challenges and Future Directions

Generative algorithms are powerful, but they still face challenges. The technology also points toward an exciting future for the denim industry. Brands are working to solve current problems while exploring new ways to use artificial intelligence.

Overcoming Technical Hurdles

Making an AI-generated pattern look realistic is a major hurdle. A digital wash must adapt to different fabric weights and textures to appear authentic. Integrating this digital design with physical production is also complex. New artificial intelligence tools help bridge this gap.

- AI software can now generate production-ready sewing patterns from a simple sketch.

- It automatically adds details like seam allowances and notches.

- 3D simulation allows designers to see how a garment will fit and move on a virtual model before making a physical sample.

The Next Frontier: Interactive AI

The future of retail includes more direct customer interaction. Imagine in-store kiosks where shoppers can design their own denim wash. Nordstrom has already explored a similar idea with its "Digital Denim Doctor" kiosk. It helps shoppers find the perfect fit. Augmented reality (AR) takes this a step further. Customers could use their phone's camera to see an AI-generated wash appear on their body in real-time, creating a virtual dressing room experience.

AI-Powered Trend Prediction

Companies are already using AI to predict the next big thing in fashion. Trend forecasting firms like Heuritech use AI to analyze millions of social media images. This helps them spot new trends early. This technology looks at specific data points to understand what customers want. It analyzes:

- Social Media: AI monitors styles on platforms like TikTok and Instagram.

- Sales Data: It tracks which items are selling quickly.

- Customer Reviews: It processes feedback to learn about preferences.

This data helps brands make smarter decisions about future colors, fits, and fabrics.

Generative algorithms are reshaping the denim industry today. This technology creates a better denim process. It offers a unique custom wash, a faster production cycle, and a cleaner finish. This innovation moves denim from a manual craft to a precise, digital medium. It defines the next era of personalized fashion and a new future for the denim wash finish.

Beyond a single wash, AI will reshape the entire shopping experience:

- It will tailor web pages and clothing options to each shopper.

- AI chatbots will provide advanced, multilingual customer support.

- It will analyze data for precise trend prediction and marketing.

FAQ

What is a generative algorithm?

A generative algorithm is a type of artificial intelligence. It learns from existing data, like photos of jeans. The AI then uses this knowledge to create completely new and original designs. It is a tool for digital creation.

Will AI replace denim designers?

No, AI will not replace human designers. Instead, it acts as a powerful tool. Designers use AI to explore new ideas quickly and bring their creative visions to life. This technology supports human creativity, it does not replace it.

How does this technology help the environment? 🌎

AI-guided lasers create denim washes with very little water. This process also removes the need for harmful chemicals used in traditional methods. It makes denim production much cleaner and safer for the planet.

Can I design my own jeans with AI today?

Some brands already offer personalization options. The ability for customers to use AI directly is still growing. Soon, you may see in-store kiosks or apps that let you co-create your own unique denim wash in real-time.

See Also

AI's Role in Managing Rapid Viral Trends in Fast Fashion

Machine Learning: Forecasting Fashion Trends to Significantly Boost Sales

Innovative AI Solutions for Sustainable Fashion and a Greener Planet

Future of Fashion Retail: Predictive Modeling Strategies for 2025

Optimizing Textile Production: AI Predictive Maintenance Strategies for 2025