ML Models Predict Fabric Performance

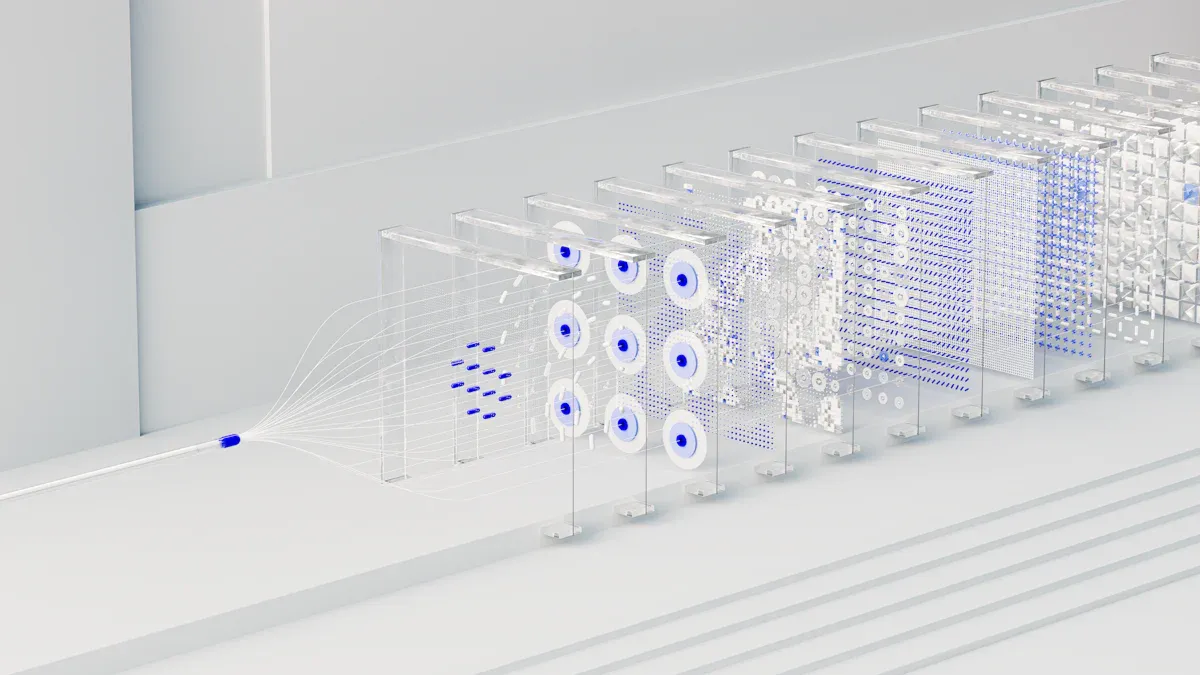

By 2025, machine learning is revolutionizing the textile industry. It allows manufacturers to accurately predict fabric performance before production even begins. This technology works by analyzing vast datasets on fiber properties, yarn structure, and weave patterns.

How It Works: ⚙️ Advanced algorithms, such as Convolutional Neural Networks (CNNs), analyze everything from fiber composition to yarn tenacity. These models then forecast key durability metrics. They predict outcomes like abrasion resistance, pilling, and tear strength with high accuracy.

Core Predictive Models in Textiles

Machine learning uses specific types of models to predict fabric performance. These models act like specialized tools. Each tool is designed for a different task, from measuring strength to analyzing surface quality. Two primary model types lead this innovation: regression models and classification models.

Forecasting Durability and Strength

Predicting a fabric's durability involves forecasting specific, measurable values. This is where regression models excel. They predict continuous outcomes, like a number on a scale.

-

Regression Models forecast values such as tensile strength or abrasion resistance cycles. Research shows that Multiple Linear Regression (MLR) models can effectively forecast fabric properties like fuzz formation. Other powerful regression algorithms include Gradient Boosting. Studies often compare different models to find the best fit. For instance, comparative analyses show that Random Forest models can achieve very high accuracy, with R² scores reaching 0.91 in predicting material strength.

-

Classification Models sort outcomes into distinct categories. A Random Forest or Logistic Regression model does not provide a specific number. Instead, it assigns a label. For example, it might predict a pilling grade from 1 (no pilling) to 5 (severe pilling). It can also deliver a simple pass/fail verdict for a quality control test.

Model Showdown: Regression vs. Classification 📊

Model Type What It Does Example Question It Answers Regression Predicts a continuous number. "How many cycles can this fabric withstand before tearing?" Classification Assigns a category or label. "Will this fabric receive a pilling grade of 3, 4, or 5?"

Analyzing Surface and Production Defects

Surface defects like pilling, snagging, and color fading ruin a fabric's appearance. Convolutional Neural Networks (CNNs) are exceptionally good at identifying these issues before they become visible.

CNNs work like a human brain learning to recognize objects. Engineers train these networks using thousands of images of both new and worn fabrics. The CNN learns to spot microscopic patterns, fiber breaks, and color variations that are invisible to the naked eye. By recognizing these early indicators, the model accurately predicts a fabric's susceptibility to future surface defects. A model like ResNet-50 can achieve 99.3% accuracy in classifying woven fabric types, which helps evaluate yarn quality for tactile properties.

Predicting Fabric Handfeel

"Handfeel" describes how a fabric feels to the touch—its softness, smoothness, and drape. This quality is subjective, making it difficult to measure. However, machine learning translates human perception into objective data.

First, experts create the necessary training data. Sensory panels with human subjects touch and rate fabric samples. They might use an eleven-point scale to score attributes like roughness or softness. This process quantifies subjective feelings into numerical data.

Next, advanced systems use this data to learn.

- Adaptive Network-based Fuzzy Inference Systems (ANFIS) are particularly useful. They combine neural networks with fuzzy logic. This allows them to process human language and create "IF-THEN" rules that map physical properties to sensory feelings.

- Deep Learning Models like Transformers and XGBoost analyze microscopic images and structural data. They correlate weave parameters with handfeel predictions. For example, XGBoost has reached 98.7% accuracy in texture classification, while Transformer models achieve 99.01% accuracy in predicting key material parameters.

- Artificial Neural Networks (ANNs) also show a strong ability to link instrumental measurements with subjective handfeel assessments. They can predict tactile comfort with a high correlation (0.82) to human ratings.

These models learn the complex relationships between a fabric's structure and the way it feels. This allows designers to engineer a desired handfeel directly from the design stage.

The Data Fueling Predictive Accuracy

Accurate predictions depend on high-quality data. Machine learning models are only as smart as the information they learn from. The textile industry gathers specific data points at every stage, from raw fiber to finished fabric, to build a complete digital picture.

Essential Fabric Data Points

Models need a detailed recipe of the fabric to work correctly. Engineers collect four main types of data:

- Fiber Composition: This includes the type of fiber (like cotton or polyester) and its percentage in the blend.

- Yarn Characteristics: This covers yarn thickness, density, and twist. The amount of twist is a key factor. Some studies show that fabric tear strength increases with yarn twist, while other research reports an inconsistent relationship.

- Fabric Structure: This describes the weave or knit pattern, along with the density of the threads.

- Finishing Treatments: This notes any chemical finishes applied for features like water resistance or flame retardancy.

Modern Data Collection Methods

Modern technology allows for faster and more precise data collection without damaging the material. These non-destructive methods provide the rich data that ML models need.

🔬 Advanced Analysis Techniques Digital imaging and spectroscopy are key tools. Techniques like Scanning Electron Microscopy (SEM) provide high-resolution images of fiber structure. Ultrasonic testing can automatically identify a fabric's weave pattern quickly and accurately.

Additionally, Internet of Things (IoT) sensors on looms collect real-time production data. These small, wireless devices monitor factors like temperature, machine vibration, and pressure during manufacturing. They send this constant stream of information to a central system where AI algorithms analyze it to spot patterns and prevent errors.

The Role of Digital Twins

A digital twin is a virtual copy of a physical fabric. It exists entirely in a computer simulation. By feeding all the essential data points into this model, engineers can test performance virtually. For instance, Levi's uses digital twin simulations to see how jeans hold up after many washes. This process reduces the need for creating and destroying numerous physical samples. Using a digital twin helps engineers predict fabric performance with greater confidence before a single thread is woven.

How ML is Used to Predict Fabric Performance

Machine learning models do more than just generate data. They provide powerful tools that transform how textiles are designed, produced, and sold. These predictions lead to tangible benefits, including faster innovation, less waste, and better products for consumers.

Enabling Virtual Prototyping

Traditional product development is slow and costly. It requires creating many physical samples. Each sample uses up materials, time, and labor. Virtual prototyping changes this entire process. It allows designers to create and test fabrics in a digital environment.

🚀 The Virtual Advantage Virtual prototyping software creates 3D simulations of a product. This approach eliminates the need for most physical models. Companies can save up to 60% in development costs. Machine learning algorithms even suggest automatic enhancements to improve performance. Engineers can explore thousands of design options on a computer. They test and refine the digital model until it is perfect. This process greatly reduces development time and speeds up the product's journey to market.

Reducing Material Waste

The textile industry produces a significant amount of waste. Predictive analytics offers a powerful solution to this problem. By optimizing processes, manufacturers can drastically cut down on discarded material. For example, one case study showed a textile manufacturer reduced inventory waste by 20% after implementing predictive models.

A major source of waste comes from cutting fabric into pattern pieces. AI-driven systems optimize this step with incredible efficiency.

- Smart Pattern Layout: AI algorithms analyze garment designs and fabric properties. They calculate the most efficient layout for pattern pieces, much like a complex puzzle. This minimizes the amount of leftover scrap fabric.

- Flaw Detection: Computer vision systems scan the fabric surface. They instantly identify flaws, color variations, or differences in thickness. The system adjusts the cutting pattern in real-time to work around these defects.

- Precision Cutting: AI-powered machines automate the cutting process. They execute the optimized patterns with high precision. This reduces the human errors that often lead to wasted material in traditional methods.

Delivering Reliable Consumer Products

Consumers want products that last. Brands can now use data to prove their fabric's quality. Machine learning models provide the specific performance metrics needed to back up marketing claims about durability and comfort. This data-driven approach builds trust and ensures customer satisfaction.

Companies use various models to predict fabric performance and guarantee quality.

- Texture and Weave: Algorithms like XGBoost and Random Forest (RF) can predict a fabric's texture and structural parameters with high accuracy.

- Defect Detection: Deep learning models like Convolutional Neural Networks (CNNs) are essential for quality control. They automatically spot fabric defects during production.

- Comfort and Feel: Artificial Neural Networks (ANNs) can predict how a fabric will feel to the touch. These predictions show a strong correlation (0.82) with human assessments, helping designers engineer a specific handfeel.

By using these predictions, brands can confidently market their products as durable, comfortable, and high-quality. They have the scientific data to support their claims.

The Future of Textile Innovation

Machine learning is not just improving current methods. It is paving the way for entirely new approaches to textile design and management. The future of the industry looks smarter, faster, and more sustainable.

Generative AI in Fabric Design

Generative AI is a creative partner for textile designers. This technology can invent completely new fabric structures. Researchers at MIT use AI to learn from existing textile databases. The AI then designs novel physical weaves that automated looms can produce.

This algorithmic approach allows designers to set specific goals. The model can generate and test solutions to meet performance constraints. It uses multi-objective optimization to balance competing needs. For example, it can design a fabric that maximizes strength while minimizing material usage. This process helps create fabrics with sustainable properties, like biodegradability, built directly into their design.

Real-Time Wear Prediction

Current models predict performance before manufacturing. The next step is predicting wear and tear as it happens. Future smart textiles may include tiny, embedded sensors. These sensors will collect data on stress, abrasion, and environmental exposure throughout a garment's life.

🔮 A Glimpse into the Future An AI system could analyze this real-time data. It might send an alert to a user's phone, suggesting it is time to repair a weak spot before a tear occurs. This technology promises to extend product life and change how consumers care for their clothes.

Smart Waste and Rework Management

AI is also making the end of the production cycle more efficient. It helps identify the root causes of fabric defects and manages waste with incredible precision.

- Root Cause Analysis: Systems like AI2Eye give factories data-driven insights. They pinpoint why recurring flaws happen. This allows managers to fix the core problem, reduce waste, and improve overall quality.

- Automated Sorting: AI is transforming how textile mills handle scrap materials. Smart systems use cameras and deep learning to automatically sort items on conveyor belts. AI-powered machines can process up to 160 items per minute, far more than human workers. Technologies using online near-infrared spectroscopy can even identify different fabric types for efficient recycling.

By 2025, machine learning is a standard tool in textile science. It is no longer a novelty. The industry has started to embrace these models to improve production.

“These types of models can offer powerful tools in cutting down on waste and improving productivity in continuous dyeing, which accounts for over 60% of dyed fabrics.”

ML models translate raw data into clear predictions. This helps companies create stronger and more sustainable fabrics. This ability to predict fabric performance sets a new benchmark for quality and innovation across the industry.

FAQ

What types of fabrics can ML models analyze?

Machine learning models analyze a wide range of fabrics. This includes natural fibers like cotton and synthetic materials like polyester. The technology works for both woven and knit structures. This versatility makes the models useful across the entire textile industry.

How does AI help make clothes better for me?

AI helps brands create more reliable products for consumers. Predictive models ensure fabrics meet high standards for durability and comfort. This means the clothes you buy are less likely to tear or fade, offering better value and longer-lasting quality. ✅

Are these AI predictions always accurate?

The predictions are highly accurate. Many models achieve over 90% accuracy in forecasting properties like strength. A model's success depends on the quality of its training data. Better data helps the system make more reliable predictions about fabric performance.

Does this technology replace human designers?

No, this technology acts as a powerful tool for designers. 🧑🎨 AI suggests new fabric ideas and helps test them virtually. This partnership speeds up innovation. It allows designers to focus on creativity while ensuring the final product meets performance goals.

See Also

Leveraging AI for Proactive Maintenance in the Textile Industry by 2025

Revolutionizing Fashion Retail with Advanced Predictive Models by Twenty Twenty-Five

Achieving Equilibrium: Predictive Analytics Optimizes Fashion Supply and Consumer Demand

Unlock Precise Fashion Predictions Utilizing Comprehensive Sales Data Insights

Machine Learning's Role in Forecasting Fashion Trends and Driving Sales Growth