How Innovative Technologies Are Transforming Material Handling

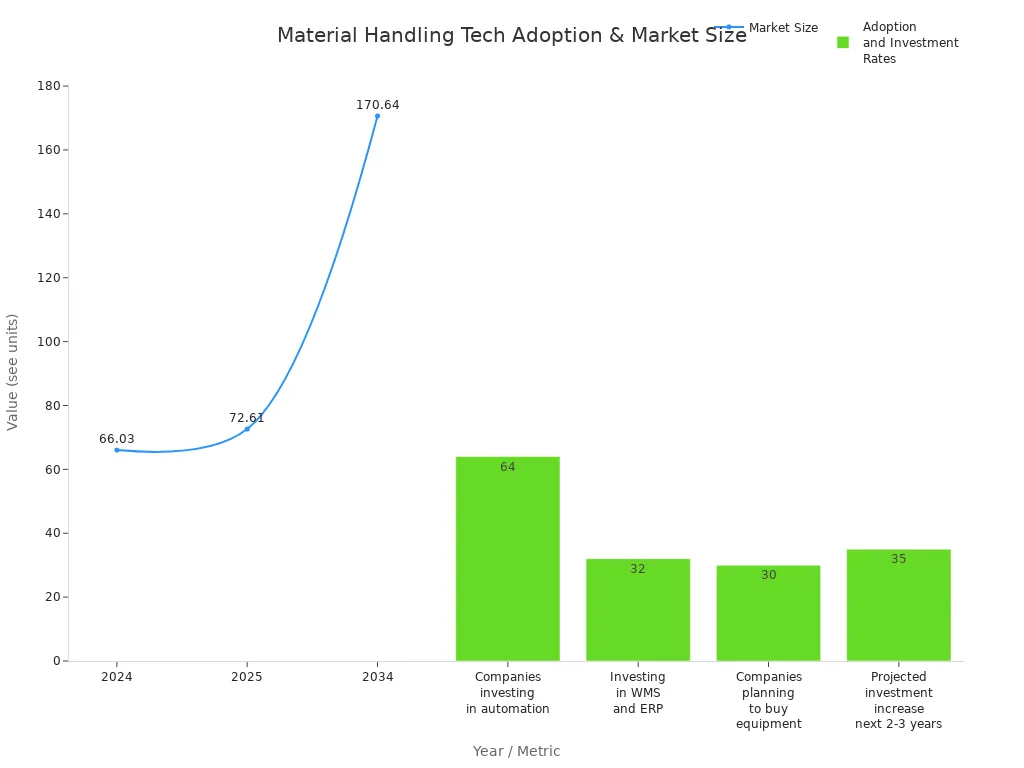

Innovative technologies are reshaping warehouse material handling at an unprecedented pace. Warehousing faces urgent change, driven by customer demand for fast, accurate delivery and rising supply chain complexity. Automation, robotics, and advanced technologies like AI, IoT, and drones now lead this transformation. Companies invest heavily in these solutions, as shown below:

| Statistic / Metric | Value / Insight |

|---|---|

| Percentage of companies investing in automation | 64% |

| CAGR of automated equipment market (2025-2034) | 9.96% |

| Projected investment increase (next 2-3 years) | 35% |

These transformative technologies boost efficiency, safety, and sustainability, giving warehouses a vital competitive edge. Every warehouse leader should consider how innovation and automation could advance their own material handling operations.

Transformation Drivers

Customer Demands

Customer expectations have changed the landscape of warehousing. Today’s consumers want fast, accurate delivery and more personalized products. Companies now use automation and robotics to meet these demands. For example, Amazon deploys robotic systems to speed up order processing and reduce errors. E-commerce businesses rely on advanced sorting systems and algorithms to streamline workflows. AI-driven robotic arms help with precision picking and packing, which lowers return rates. Real-time tracking with IoT devices and RFID tags gives customers up-to-date information about their orders. Flexible material handling solutions, such as modular designs and specialized packaging, support customization. Predictive analytics optimize delivery routes, making shipments more reliable. Employee training ensures that staff can operate new technologies efficiently. These changes in warehousing operations lead to higher customer satisfaction and loyalty.

Supply Chain Complexity

Modern supply chains have grown more complex. Factors such as a larger supplier base, greater product diversity, and wider geographic spread create new challenges for warehouse operations. Regulatory requirements and technological integration add more layers of difficulty. Increased complexity can cause delays, bottlenecks, and higher costs. Warehousing systems must adapt by using process standardization, supplier collaboration, and advanced technology. Geographic spread and regulatory differences make transportation and storage more complicated. Data silos from new technologies can reduce transparency and slow down coordination. Companies invest in optimized layouts and ergonomic solutions to address these issues. As a result, warehousing strategies now focus on resilience and efficiency to keep up with global demands.

Labor and Safety

Labor and safety remain top concerns in the material handling industry. Overcrowded and shrinking workspaces increase the risk of injuries. Manual handling often leads to slower processes and more errors, which can compromise safety. Equipment breakdowns disrupt workflow and create hazards. The workforce is aging, with more workers over 55, which raises the risk of strain and fatigue. Industry regulations continue to change, requiring regular inspections, training, and safe equipment use. Companies respond by improving ergonomics, maintaining equipment, and investing in automation. These steps help protect workers and ensure compliance. Warehousing leaders recognize that a safe, efficient workplace supports productivity and reduces costs.

Innovative Technologies

Automation

Automation stands at the core of modern warehouse material handling. Companies use automated systems to move, sort, and store goods with speed and accuracy. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) transport materials across the warehouse floor, reducing the need for human-operated forklifts. Conveyor systems with AI-driven controls adapt to changing loads and optimize material flow. Automated Storage and Retrieval Systems (AS/RS) use robotic shuttles and cranes to increase storage density and retrieval speed. These advanced technologies help warehouses achieve higher throughput, reduce manual handling, and improve space utilization.

| Material Handling Stage | Common Automation Applications | Measurable Benefits |

|---|---|---|

| Receiving & Unloading | Conveyor systems, autonomous forklifts, barcode scanners, RFID, robotic depalletizers | Reduced manual data entry, faster unloading, improved inventory identification |

| Storage & Picking | AGVs, AMRs, AS/RS including vertical lift modules, cube-based systems, mobile AS/RS | Dense storage, high-speed retrieval, maximum space utilization, increased throughput, reduced manual handling |

| Packing | Machines for sealing, labeling, boxing; scan and weigh systems | Error prevention, faster packing, improved package verification |

| Sorting & Staging | Automated sortation systems with barcode/RFID scanners, conveyor belts, diverters | Faster, more organized sorting, reduced errors |

| Shipping & Loading | Conveyor-to-truck loading systems, dock scheduling software, load scanners | Accelerated outbound movement, optimized dock usage, shipment verification |

| Inventory Management | RFID tracking, automated cycle counting robots, Warehouse Management System (WMS) | Improved location visibility, accuracy, reduced labor costs, centralized control |

Automation delivers measurable results. For example, Ariat installed an automated goods-to-person system with 86 robots and 7 picking stations. This setup increased the picking rate tenfold and allowed the company to process over 1,650 lines per hour with only seven employees. Automation also shifted 80% of picking labor to more valuable tasks, supporting efficient management of thousands of SKUs and enabling next-day shipping.

Tip: Automation and innovation in warehouse material handling not only boost productivity but also improve worker safety by reducing manual lifting and repetitive tasks.

Robotics

Robotics has become a driving force in warehousing. Companies deploy industrial robot arms for heavy lifting and hazardous tasks, while mobile robots transport goods across the facility. Collaborative robots, or cobots, work safely alongside humans, handling repetitive or dangerous jobs. Picking robots use vision systems and AI to sort and inspect items with high precision. Gantry robots manage large, heavy loads with scalability and cost efficiency.

Robotics integrates seamlessly with warehouse management systems (WMS), enabling real-time data exchange and dynamic task optimization. The latest trends include increased autonomy through AI and machine learning, collaborative robotics for safe human-robot interaction, and Robotics as a Service (RaaS) models that lower upfront costs. Companies also focus on sustainability, using energy-efficient and green robotics to reduce environmental impact.

| Aspect | Description |

|---|---|

| Integration with WMS | Robots communicate with WMS for real-time data, task optimization, and tracking. |

| Types of Robots | Industrial arms, mobile robots, cobots, picking robots, gantry robots. |

| Latest Trends | AI-driven autonomy, collaborative robotics, RaaS, IoT connectivity, sustainability. |

| Use Cases | Order picking, packaging, inventory auditing, material transport. |

| Benefits | Efficiency, safety, scalability, cost-effectiveness, workflow optimization. |

Advanced AI and robotics enable continuous operation, minimize errors, and improve workflow. For example, Amazon uses coordinated robots and AGVs to increase operational efficiency by 20% and reduce picking errors by 30%.

IoT

The Internet of Things (IoT) connects devices, people, and locations in the warehouse. IoT sensors and RFID tags track goods in real time, providing instant visibility into inventory and order status. Autonomous mobile robots, connected through IoT, navigate the warehouse using sensors and AI to pick, sort, and transport goods. This connectivity reduces labor strain and improves safety.

IoT supports predictive maintenance by monitoring equipment health and alerting staff before breakdowns occur. Real-time data capture and analysis help managers make quick decisions, optimize logistics, and prevent stockouts or overstocking. Integration with warehouse management systems and enterprise resource planning (ERP) software enhances coordination across the supply chain.

- IoT enables real-time tracking of products, assets, and equipment.

- Predictive maintenance reduces downtime and extends equipment life.

- Data-driven decision making improves efficiency and customer satisfaction.

- IoT enhances transparency, flexibility, and scalability in smart logistics.

Drones

Drones represent one of the most cutting-edge warehouse technologies for inventory management. Equipped with cameras and sensors, drones scan barcodes and QR codes on inventory items. They use warehouse maps and obstacle detection to navigate safely and autonomously. Drones collect digital images and send data to the warehouse management system, which updates inventory records in real time.

Drones reduce the time needed for inventory checks from days to hours. They access hard-to-reach areas, improving accuracy and detecting misplaced stock. Drones also enhance worker safety by reducing the need for employees to climb ladders or operate heavy machinery. Companies use drones for warehouse inspections, intra-warehouse deliveries, and security monitoring. These devices lower labor costs, minimize errors, and provide continuous updates on stock levels.

Note: GEODIS reported a 50% increase in inventory accuracy and significant reductions in audit times after deploying drones in their warehouses.

Wearables

Wearable technology is transforming worker productivity and safety in material handling. Devices such as smart glasses, augmented reality (AR) headsets, and exoskeletons support hands-free operation and real-time data access. Workers receive step-by-step instructions, hazard warnings, and location tracking through these devices.

Wearables improve picking accuracy and speed. For example, BMW reported a 25% improvement in operational accuracy and a 20% reduction in workplace injuries after introducing smart glasses. Ergonomic designs reduce physical strain, and intuitive interfaces require minimal training. Wearables also support emergency response by enabling quick location tracking.

-

Benefits:

- Enhanced worker safety and reduced injuries.

- Increased productivity and continuous workflows.

- Real-time data access for better decision-making.

- Improved integration with warehouse management systems.

- Ergonomic comfort and minimal training needs.

-

Challenges:

- High initial and ongoing costs.

- Worker resistance and privacy concerns.

- Need for compatibility with existing systems.

Wearables, along with other innovative technologies, help warehouses achieve higher efficiency, safety, and sustainability.

AI in Warehousing

Predictive Analytics

Artificial intelligence and machine learning have changed how warehouses manage inventory. AI-driven inventory management uses predictive analytics to forecast demand, spot trends, and recommend when to reorder products. Warehouse management systems now use these tools to keep stock levels balanced and avoid both shortages and excess. AI analyzes sales data, supplier information, and seasonal patterns to help companies plan ahead. This approach reduces stockouts and overstocking, lowers costs, and improves customer satisfaction.

- AI-powered inventory management:

- Anticipates demand and seasonal changes.

- Recommends the best time to reorder.

- Minimizes errors in picking and order processing.

- Helps companies respond quickly to supply chain disruptions.

Many warehouses report faster order processing and better delivery speeds after using predictive analytics. Companies also use these insights to plan labor, space, and equipment needs more effectively.

Process Optimization

AI helps warehouses run more smoothly by automating tasks and improving workflows. It identifies bottlenecks and suggests ways to fix them. AI-driven systems track inventory in real time and adjust restocking schedules automatically. This reduces manual work and cuts down on mistakes.

- AI-driven automation increases throughput by removing manual steps.

- Modular warehouse management systems adapt to changing needs.

- AI lowers costs by improving accuracy and efficiency.

- Real-time tracking helps managers make quick decisions.

- Automated replenishment ensures products are always available.

AI also improves labor allocation by assigning workers to the most important tasks. Companies see higher profit margins, fewer disruptions, and better safety as a result.

Computer Vision

Computer vision uses smart cameras and sensors to track inventory and monitor warehouse activities. These systems can follow every pallet or box as it moves through the facility. AI-powered cameras on forklifts and drones provide real-time updates and help managers spot problems quickly.

- Computer vision systems:

- Track all pallet movements automatically.

- Offer dashboards with insights to boost productivity and safety.

- Work with any material handling equipment or real-time location system.

- Use edge computing for fast data processing.

Recent advances allow computer vision to process data close to where it is collected, making decisions faster and reducing errors. Companies use these tools to improve inventory management, reduce losses, and make better decisions. Research shows that even with some challenges, computer vision and AI continue to transform warehouse operations.

Warehouse Automation

AGVs and AMRs

Warehouse automation relies on advanced vehicles to move goods efficiently. Automated guided vehicles perform repetitive tasks along fixed routes, such as transporting bulk items or replenishing inventory. These vehicles follow physical markers and require stable environments. In contrast, autonomous mobile robots use sensors, cameras, and AI to navigate dynamic warehouse layouts. They adapt routes in real time, making them ideal for flexible operations and narrow aisles.

Both AGVs and AMRs integrate with warehouse management systems to automate material flow. They support goods-to-person picking, kit transport, and safe handling of sensitive materials. E-commerce, automotive, and pharmaceutical sectors use these solutions to boost throughput and reduce labor costs. AMRs offer quick deployment and scalability, while AGVs suit environments with consistent workflows. Together, these technologies form the backbone of modern warehouse automation solutions.

- AGVs: Fixed routes, high reliability, best for stable tasks.

- AMRs: Dynamic navigation, flexible, ideal for changing layouts.

- Both: Improve safety, reduce manual labor, and optimize resource planning.

Automated Storage

Automated storage and retrieval systems transform how warehouses handle inventory. These systems operate continuously, increasing productivity and availability. Automated storage and retrieval systems deliver goods directly to operators, reducing walking and searching time. They use integrated software to update inventory in real time, ensuring accurate product tracking.

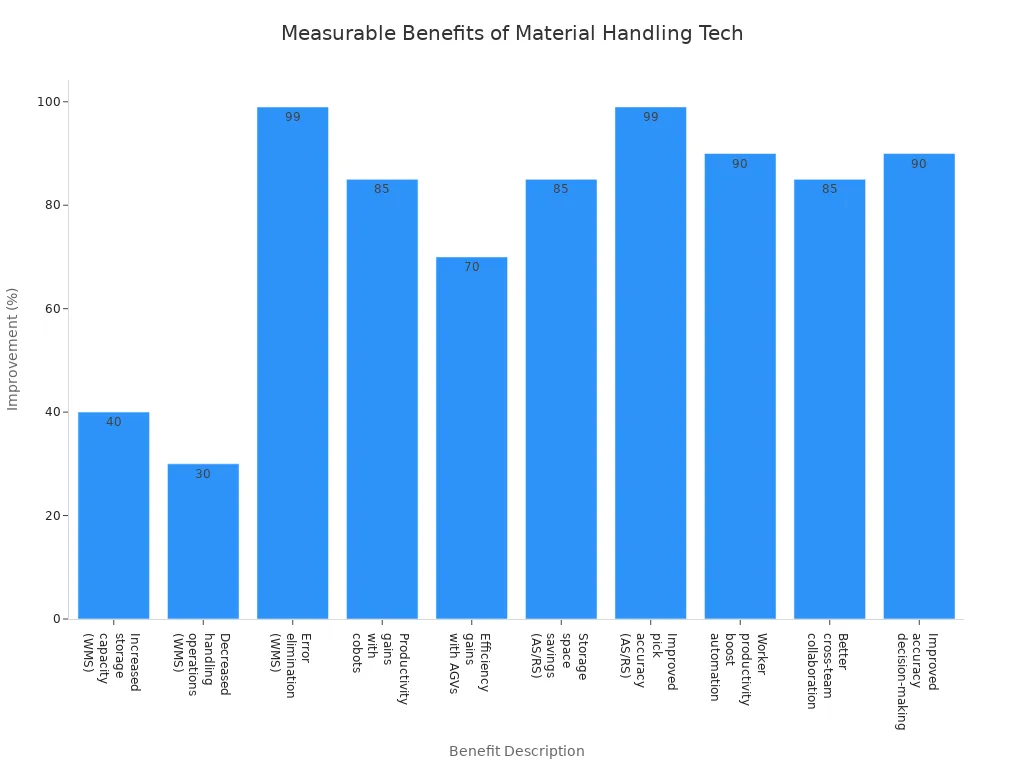

Autonomous storage and retrieval systems maximize space by using vertical layouts and optimizing storage density. They improve safety by limiting human access to hazardous areas and providing ergonomic workstations. Automated storage and retrieval system technology reduces labor costs and order errors, while enhancing security and traceability. Many warehouses report up to 85% space savings and 99.9% pick accuracy after adopting these systems.

- Continuous operation and real-time inventory control.

- Enhanced safety and reduced labor requirements.

- Scalable and adaptable for future expansion.

Conveyor Systems

Conveyor systems play a vital role in warehouse automation. Automated conveyors create smooth, predictable flow paths for goods, eliminating manual handling gaps. Modular designs allow easy adaptation to changing product lines and warehouse layouts. These systems integrate with robotics, AGVs, and IoT devices to support efficient material movement.

Advanced conveyor systems use sensors, AI analytics, and real-time monitoring to optimize sorting and prevent downtime. They reduce labor costs and improve worker safety by automating heavy lifting and repetitive tasks. Integration with warehouse management software enables precise tracking and dynamic routing. Many warehouses see faster order processing and improved inventory accuracy after implementing conveyor automation.

- Increased throughput and reduced bottlenecks.

- Flexible, scalable layouts for growing demands.

- Enhanced safety and lower operational costs.

Tip: Combining automated storage, conveyors, and robotics creates a seamless warehouse automation environment that boosts efficiency and supports future growth.

Smart Warehousing

Connected Systems

Smart warehousing revolutionizes the industry by creating a data-driven, automated, and interconnected environment. Connected systems form the backbone of this transformation. These systems combine IoT sensors, advanced warehouse management systems, and robotics to automate and monitor every step of the process. IoT sensors track inventory, equipment health, and environmental conditions in real time. Robots and autonomous vehicles transport goods, while AI-driven software makes decisions to optimize workflows.

Key technologies in connected systems include:

- IoT sensors for real-time tracking and predictive maintenance

- Autonomous mobile robots for efficient material transport

- Vision systems for quality control and safety monitoring

- Warehouse management systems that collect and analyze operational data

These connected systems enable real-time visibility into inventory management and operations. They help managers detect and resolve issues quickly, reducing errors and downtime. Warehouse control systems interface directly with automated equipment, issuing commands and optimizing workflows. Security remains a top priority, with measures such as secure cloud platforms, role-based access, and regular firmware updates.

Note: Retrofitting smart warehouse capabilities into older buildings is possible using modular IoT devices, cloud-based software, and mobile robots.

Data Integration

Data integration stands at the core of smart warehousing. It brings together information from multiple sources, such as IoT devices, warehouse management systems, and robotics, to support better decision-making. Best practices for integrating data include:

- Define clear business objectives and involve all stakeholders.

- Assess existing data sources for quality and relevance.

- Design a scalable architecture, whether on-premises, cloud, or hybrid.

- Select integration tools that fit operational needs, such as ETL or Change Data Capture.

- Implement strong security measures, including encryption and access controls.

- Monitor costs and automate processes to improve efficiency.

Advanced warehouse management systems rely on integrated data to optimize inventory management, automate replenishment, and track performance. Clean, standardized data ensures accuracy and timeliness. Ongoing monitoring and maintenance keep data quality high and support compliance with security regulations.

Tip: Aligning integration projects with business goals and securing buy-in from technology and business leaders increases the success of smart warehousing initiatives.

Benefits

Efficiency

Warehouse automation drives operational efficiency by automating repetitive tasks and enabling continuous workflows. Robotics, AGVs, and AI-powered systems handle picking, packing, and sorting without breaks. This approach increases speed and reduces errors. Companies like Cainiao have seen a 70% drop in staff labor after deploying warehouse robots. Real-time data collection and analytics help managers optimize resources and minimize downtime. The integration of automation and robotics allows warehouses to process more orders with fewer delays, improving overall operational efficiency.

| Benefit Description | Measurable Improvement |

|---|---|

| Increased storage capacity (via WMS) | Up to 40% |

| Decreased handling operations (via WMS) | Up to 30% |

| Productivity gains with human-cobot teams | 85% more productive |

| Efficiency gains with AGVs | 50-70% |

| Worker productivity boost due to automation | 90% increase |

| Time freed up by autonomous vehicles | 30-50% of a worker's time |

Cost Savings

Warehouse automation reduces labor costs, energy use, and waste. Automated systems lower the need for manual labor, cutting wages, training, and injury expenses. Companies like SMC doubled throughput without overtime, while Davcor reduced monthly electricity bills from $9,000 to $1,200 after adopting AutoStore. Improved space utilization and fewer product errors also contribute to significant cost savings.

| Cost Saving Category | Description | Example/Impact |

|---|---|---|

| Labor Cost Reduction | Automation reduces manual labor needs, lowering wages, training, injury, and turnover costs. | Automated Guided Vehicles (AGVs) reduce manual transport labor. |

| Increased Throughput | Higher production speed lowers per-unit costs. | SMC doubled throughput, processing 12,000 order lines daily without overtime. |

| Reduced Product Damage/Waste | Precision reduces errors and defects, minimizing costly waste. | Custom work positioners reduce assembly errors and rework costs. |

| Energy Efficiency | Advanced sensors and controls lower energy consumption and operational expenses. | Davcor cut electricity bills from $9,000 to $1,200 monthly after adopting AutoStore. |

| Space Utilization | Automated lifts and systems optimize facility space and workflow. | Multi-stage lifts automate vertical handling, improving space use and workflow efficiency. |

Safety

Smart warehousing solutions enhance safety by automating hazardous tasks and reducing physical strain. Collaborative robots and AGVs handle heavy lifting and repetitive jobs, lowering injury risks. AI-powered safety systems detect and prevent accidents in real time. Amazon reported a 15% decrease in incident rates after introducing cobots. Advanced sensors and navigation systems further reduce collisions and injuries, creating safer environments for workers.

Accuracy

Automation and smart warehousing technologies improve accuracy in inventory management and order fulfillment. RFID, IoT, and barcode scanning enable real-time tracking and frequent automated audits. Automated picking and packing reduce human errors, raising pick accuracy to 99%. These improvements lead to faster processing, fewer mistakes, and higher customer satisfaction.

- Real-time inventory tracking ensures precise stock levels.

- Automated audits allow immediate correction of discrepancies.

- Integration with warehouse management systems streamlines data flow.

- Automation reduces picking errors from one in 300 to one in a million.

Sustainability

Eco-friendly solutions in material handling support sustainability goals. Warehouses use recycled pallets, energy-efficient lighting, and renewable energy sources. Automation optimizes route planning and reduces fuel use. Companies implement recycling programs and minimize packaging waste. Electric forklifts and smart charging systems lower emissions and energy consumption. These practices help warehouses reduce their environmental footprint and promote a circular economy.

- Durable, recycled pallets reduce landfill waste.

- Route optimization software cuts fuel use and emissions.

- Energy-efficient equipment and renewable energy lower operational impact.

- Recycling and reusability initiatives support sustainability across the supply chain.

Challenges

Investment

Adopting new material handling technologies often requires a significant financial commitment. Many organizations face high upfront costs for automation equipment, robotics, and supporting infrastructure. Leaders must carefully evaluate the return on investment, balancing immediate expenses against long-term benefits such as improved safety and efficiency. Some companies choose flexible solutions like Robots as a Service (RaaS), which bundle hardware, installation, and support to reduce initial spending. Careful planning and professional audits help organizations make informed decisions and avoid costly mistakes.

Integration

Integrating advanced technologies with existing systems presents a major challenge. Many warehouses rely on legacy software and hardware that may not work smoothly with new automation platforms. This process can be time-consuming and often requires specialized expertise or custom middleware. Integration difficulties can slow down operations and create inefficiencies. Partnering with technology experts or consultants can ease the transition and ensure that new systems work well with current processes. Flexible and scalable solutions help organizations adapt to changing needs in warehousing.

Workforce

Workforce resistance remains a significant barrier to technology adoption. Nearly 60% of warehouse employees worry about job security when automation is introduced. Many workers also struggle to adapt to new systems. Effective communication is essential. Leaders should explain that automation can make jobs safer and shift workers to more valuable tasks. Ongoing training and re-skilling programs help employees gain confidence and succeed in a changing environment. Involving staff early in the process can reduce fear and build support for new initiatives.

Security

As automation increases data flow, security and data management become critical concerns. Automated systems generate large amounts of sensitive information, raising risks related to privacy and regulatory compliance. Companies must protect data from cyber threats and unauthorized access. Advanced technologies like autonomous mobile robots with sensors, RFID, and 5G can improve data accuracy and security. Regular updates, strong access controls, and employee training help safeguard information and maintain trust in automated warehousing operations.

Adoption Steps

Needs Assessment

Every business should start with a clear needs assessment. Leaders must identify current challenges and set specific goals for improvement. They should review existing processes and equipment. Teams can use surveys or interviews to gather feedback from staff. Data analysis helps pinpoint bottlenecks and safety risks. A thorough assessment ensures that technology investments address real problems.

Tip: Involve employees from different departments during the assessment. Their insights often reveal hidden issues.

Roadmap

A detailed roadmap guides the adoption process. Leaders should outline each step, from pilot testing to full-scale deployment. The plan must include timelines, budgets, and key milestones. Teams should prioritize projects based on impact and feasibility. Regular reviews help track progress and adjust plans as needed.

Sample Roadmap Table:

| Step | Action Item | Timeline |

|---|---|---|

| Assessment | Identify needs | Month 1 |

| Vendor Selection | Evaluate solutions | Month 2 |

| Pilot Program | Test new technology | Month 3-4 |

| Full Deployment | Scale across operations | Month 5-6 |

Partnerships

Strong partnerships support successful technology adoption. Companies should seek vendors with proven expertise and reliable support. Collaboration with technology consultants can ease integration challenges. Industry associations and peer networks offer valuable advice and case studies. These partnerships help businesses stay updated on trends and best practices.

Change Management

Change management ensures smooth transitions. Leaders must communicate the benefits of new technologies to all staff. Training programs help employees build confidence with new systems. Managers should address concerns and provide ongoing support. Recognizing achievements boosts morale and encourages engagement.

Note: Effective change management reduces resistance and speeds up adoption.

Innovative technologies continue to reshape warehouse automation. Companies see gains in efficiency, safety, and sustainability. Automation and ai help leaders solve complex challenges and improve operations. Teams should assess needs, plan carefully, and invest in training. Staying informed about new trends in warehouse automation keeps businesses competitive.

Tip: Regularly review technology updates to maximize the value of automation investments.

FAQ

What is the main benefit of warehouse automation?

Warehouse automation increases efficiency. Automated systems handle repetitive tasks quickly and accurately. Companies process more orders with fewer mistakes. Workers focus on higher-value activities. This leads to faster deliveries and improved customer satisfaction.

How do robotics improve worker safety?

Robotics take over dangerous or repetitive jobs. Robots lift heavy items and move goods across the warehouse. Workers avoid injuries from lifting or repetitive motion. Safety sensors on robots help prevent accidents.

Are these technologies difficult to integrate with existing systems?

Most modern solutions offer flexible integration options. Many vendors provide support and training. Companies often use middleware or APIs to connect new tools with current software. Planning and expert help make integration smoother.

Do innovative technologies help reduce environmental impact?

Yes, many technologies support sustainability. Automated systems use less energy and optimize routes. Electric vehicles and smart lighting lower emissions. Companies also use recycled materials and reduce waste. These steps help protect the environment.

See Also

Cutting Edge Intralogistics Trends Transforming Warehouse Operations

The Importance Of SaaS WMS For Modern Warehousing Success

How EDI Tracking Advances Enhance Shipment Visibility Today

Top Three Lean Logistics Strategies To Improve Sustainability

Key Features That Differentiate WarpDriven ERP In Supply Chains