Intralogistics Innovations Shaping the Future of Warehousing

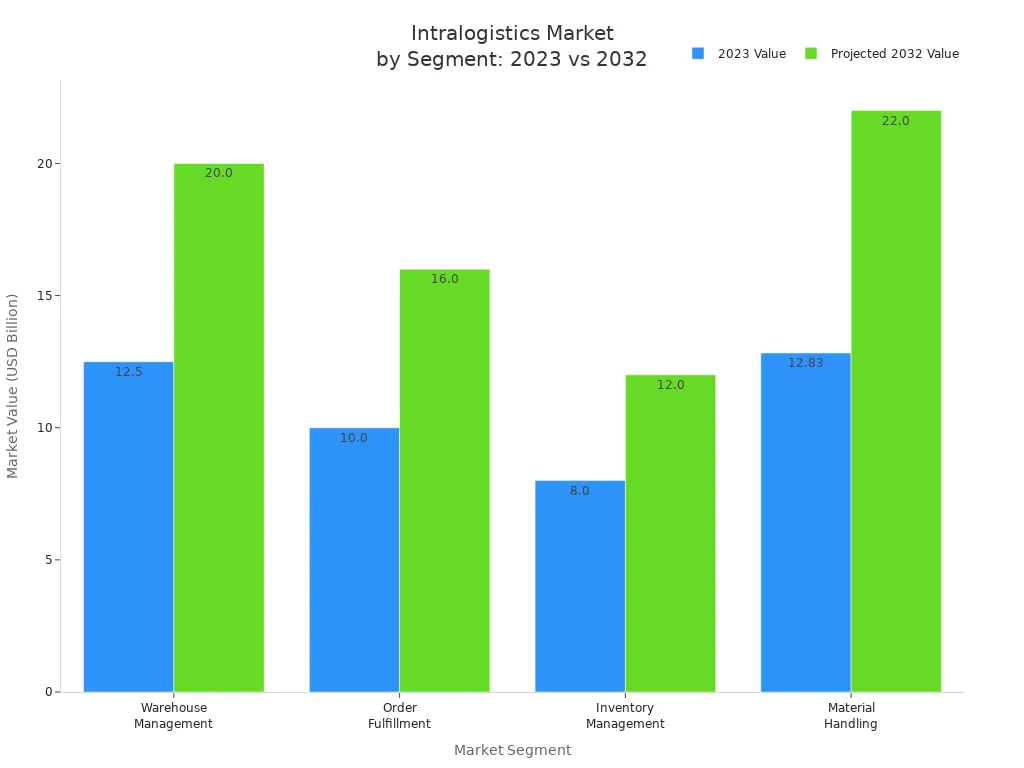

Intralogistics innovations drive a dramatic shift in warehouse efficiency. Companies rapidly adopt automation, robotics, and ai to streamline operations and reduce errors. Warehouse Management Systems now appear in 87% of third-party logistics providers, and over 4 million robots are expected in 50,000 warehouses worldwide by 2025. These advances improve productivity, safety, and collaboration. The global intralogistics market will reach $116.41 billion by 2035, fueled by demand for smarter, future-ready facilities.

Intralogistics Innovations

Intralogistics innovations represent the latest advancements that transform internal warehouse operations. These solutions focus on streamlining the movement of goods, information, and resources within a facility. Companies now rely on these technologies to create optimized warehouse processes that support faster fulfilment, higher accuracy, and better use of warehouse space.

Key Technologies

Modern warehouses deploy a range of technologies to achieve operational efficiency and support optimized warehouse processes. The most significant intralogistics innovations include:

- Brownfield warehouse automation, which allows companies to retrofit existing spaces for scalability.

- Micro-fulfilment centers and hub-and-spoke strategies, bringing fulfilment closer to customers and optimizing omni-channel supply chains.

- Advanced software orchestration, such as Swisslog's SynQ system, which integrates warehouse management, material flow, and control systems.

- Artificial intelligence and robotics, used for demand forecasting, predictive maintenance, real-time inventory management, and automating picking and packing.

- Simulation and optimization software, like Simcore, enabling 3D modeling of warehouse flows to test scenarios and optimize resources before implementation.

- Ergonomic and smart workstations, such as those from Bosch Rexroth, which improve operator conditions with adjustable height, pick-to-light systems, and connected tools.

- Autonomous robots, including Bosch Rexroth's ACTIVE Shuttle, that navigate narrow aisles and transport goods efficiently.

- Collaborative robots with integrated force sensors, allowing safe human-robot interaction and high-speed operations.

Other primary technologies driving intralogistics innovation include:

- Automated Storage and Retrieval Systems (AS/RS) for fast, accurate storage and retrieval.

- Warehouse Management Systems (WMS) for centralized control and real-time tracking.

- Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) for autonomous goods transport.

- Machine vision systems for detailed imaging and real-time optimization.

- Digital twins for simulating and analyzing warehouse operations.

- IoT integration for real-time monitoring and predictive maintenance.

- Gantry robots and mobile robotics for precise palletizing and flexible automation.

- Sustainability technologies, such as electric vehicles, supporting environmental goals.

Note: These technologies not only improve warehouse space optimisation but also enable companies to adapt quickly to changing market demands.

Workflow Optimization

Workflow optimization stands at the core of intralogistics innovations. Companies use these strategies to remove bottlenecks, minimize downtime, and boost operational efficiency across all warehouse operations. Key approaches include:

- Optimizing warehouse layout and pick paths to reduce unnecessary movement and speed up fulfilment.

- Implementing standardized procedures and scanning verification systems to lower error rates and ensure order accuracy.

- Using proactive replenishment processes to maintain inventory availability and prevent delays.

- Adopting batch and zone picking strategies to reduce travel time and increase throughput.

- Focusing on shipping maximums to identify and remove constraints that limit throughput.

- Integrating Warehouse Management Systems, which can increase productivity by up to 25%.

- Leveraging smart technologies like RFID and barcoding to reduce inventory errors by over 90%.

- Gradually introducing scalable automation solutions, such as AS/RS and autonomous mobile robots, to minimize disruption and scale efficiency.

Efficient warehouse layout planning places frequently used items closer to work areas, reducing bottlenecks. Regular maintenance and timely equipment replacement prevent unexpected breakdowns. Scheduling maintenance ensures machines receive service before failures occur, minimizing downtime. Standardizing processes improves efficiency in loading and unloading, while real-time stock tracking prevents inventory-related delays.

Emerging technologies, such as AI-driven predictive analytics and IoT sensors, provide real-time visibility and predictive maintenance. These tools anticipate equipment issues, automate repetitive tasks, and improve inventory management. As a result, companies experience less downtime and higher productivity in their warehouse operations.

Pro Tip: Continuous staff training helps teams identify new efficiency opportunities and solve problems quickly, further reducing operational interruptions.

Warehouse Automation

Warehouse automation transforms warehouse operations by introducing technology that handles repetitive and complex tasks. Companies use automation to boost efficiency, accuracy, and scalability. The most common types of warehouse automation include Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), automated storage and retrieval systems, conveyor systems, and collaborative robots. Each tool plays a unique role in streamlining operations and supporting increased productivity.

Automation Tools

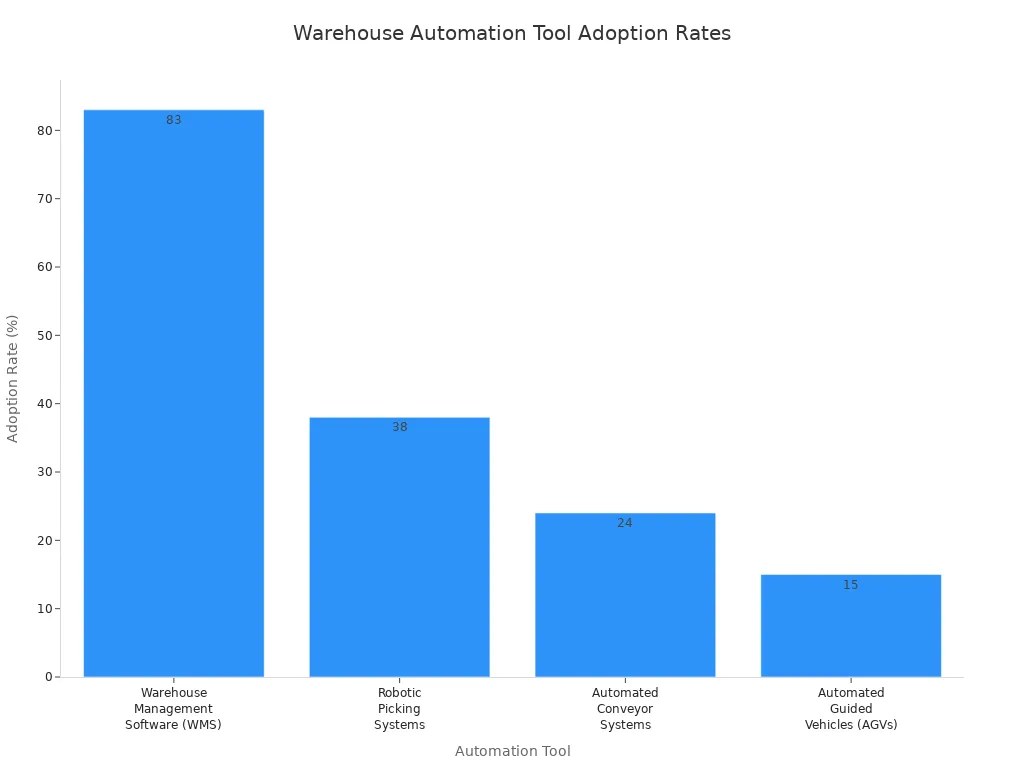

Many warehouses rely on a mix of automation tools to meet their specific needs. The table below highlights the most widely adopted solutions and their functions:

| Automation Tool | Adoption Rate | Description |

|---|---|---|

| Warehouse Management Software (WMS) | 83% | Centralizes control of warehouse operations and inventory. |

| Robotic Picking Systems | 38% | Increases picking speed and accuracy. |

| Automated Guided Vehicles (AGVs) | 15% | Moves heavy loads safely and efficiently. |

| Automated Conveyor Systems | 24% | Streamlines goods movement and reduces manual labor. |

| Automated storage and retrieval systems (AS/RS) | N/A | Maximizes space and speeds up order fulfillment. |

Warehouse automation delivers measurable benefits:

- Faster fulfillment and shipping

- Higher daily order output

- Consistent performance, even with labor shortages

- Reduced processing time and fewer errors

- Quick adaptation to volume spikes

Automation also changes labor requirements. Workers shift from manual tasks to overseeing and maintaining advanced automation systems. This shift creates new technical roles and improves workplace safety by reducing exposure to hazardous tasks.

Process Integration

Process integration ensures that automation tools work together smoothly. When companies connect inventory management, picking, and shipping systems, they reduce delays and errors. For example, automated storage and retrieval systems arrange goods for fast access, while real-time dashboards help managers make better decisions.

Key benefits of process integration include:

- Improved inventory accuracy and fewer discrepancies

- Faster handling of goods and reduced bottlenecks

- Better use of resources and space

- Fewer manual errors in data entry and picking

- Enhanced real-time data access for smarter planning

Note: Advanced automation and process integration allow warehouses to scale up without increasing labor or space. This flexibility helps companies stay competitive as demand changes.

Warehouse Robotics

Robotics Applications

Warehouse robotics now play a central role in modern warehouse operations. Companies deploy robotic technologies to handle tasks that once required manual labor. These solutions include robotic piece picking arms, autonomous mobile robots, and collaborative robots. The most common applications involve picking, packing, transporting, sorting, and palletizing.

- Plus One Robotics uses vision-guided robotic piece picking arms to manage over 500 million picks each year.

- RightHand Robotics delivers consistent accuracy with robotic piece picking arms for piece-picking automation.

- inVia Robotics reports a 400% improvement in picking efficiency using robotic piece picking arms.

- 6 River Systems employs collaborative robotic piece picking arms, achieving up to three times the pick rate.

- Exotec’s scalable fulfillment robots handle up to 400 lines per hour.

- Dematic automates order fulfillment, sorting, and palletizing for high-volume operations.

- Mujin Robotics leverages AI-powered robotic piece picking arms for real-time palletizing and sorting.

- AutoStore’s compact robotic piece picking arms increase warehouse space by four times.

- Yaskawa Motoman’s cobots handle heavy payloads up to 600 kg.

| Leading Applications of Robotics in Warehousing | Demonstrated Outcomes |

|---|---|

| Inventory management | Real-time tracking and space optimization |

| Picking and packing | Enhanced accuracy, reduced human errors |

| Transporting goods | Continuous 24/7 operation, improved efficiency |

| Palletizing | Cost efficiency, reduced labor costs |

| Sorting | Safety improvements, fewer accidents |

| Order fulfillment | Increased customer satisfaction, faster delivery |

Robotic technologies generate real-time data analytics, optimize workflows, and predict demand. These advances free human workers for higher-level tasks and reduce burnout.

Speed and Accuracy

Warehouse robotics outperform manual labor in both speed and accuracy. Robotic piece picking arms operate without fatigue, enabling continuous 24/7 production. This consistency leads to higher throughput and fewer errors. Robotic technologies use advanced sensors and precise programming, which ensures repeatable motions and reduces mistakes common in manual handling.

Automated warehouses are 76% more likely to achieve inventory accuracy of 99% or higher. Third-party logistics providers using robotics report order accuracy rates up to 99.9%. Robotics also reduce returns by 25–45% due to fewer picking and packing errors. These improvements increase customer trust and satisfaction.

Manual labor remains flexible for complex tasks, but it cannot match the speed and reliability of robotic piece picking arms in repetitive, high-volume operations. Robotic technologies automate data collection and tracking, which further boosts productivity and reduces the need for extra personnel.

Tip: Companies that invest in warehouse robotics gain a competitive edge by improving order fulfillment speed, accuracy, and overall warehouse operations.

Artificial Intelligence

Predictive Analytics

AI-powered solutions have become essential in modern warehouses. Predictive analytics uses AI to analyze historical sales, market trends, and supplier data. This process helps companies optimize inventory levels and forecast demand. Warehouses can now prevent stockouts and overstocking by using these insights. AI-powered solutions also identify patterns and predict supply chain disruptions. This allows managers to adjust procurement and distribution before problems occur.

Many warehouses use data-driven warehouse software to track sales trends, seasonal demands, and external factors like weather or social media buzz. These systems recommend the best reorder times and stock quantities. Predictive analytics also streamlines picking and packing by analyzing order priorities and pick routes. AI-powered solutions reduce errors through barcode and RFID scanning, which improves packing accuracy. Companies like FulFillor have seen order processing times drop by 25% and picking errors fall by 35% after adopting these technologies.

Tip: Predictive analytics not only improves inventory management but also supports workforce productivity and safety through AI-powered solutions.

Real-Time Data

Real-time data has transformed warehouse operations. AI-powered solutions use sensors and computer vision to provide live inventory tracking and immediate feedback. Data-driven warehouse software gives managers instant insights into stock levels, order status, and equipment health. This visibility enables proactive decision-making and faster responses to issues.

Warehouses that use real-time data see measurable improvements in key performance indicators. Inventory accuracy increases, order picking errors decrease, and order cycle times shorten. AI and machine learning models enhance predictive analytics by providing up-to-the-minute insights. These tools help companies detect delays or bottlenecks instantly and adjust logistics plans. Performance analytics also reduce downtime and optimize inventory management.

Note: Real-time data and predictive analytics work together to create a smarter, more efficient warehouse. AI-powered solutions drive continuous improvement and help companies stay competitive.

Advanced Tracking Systems

Real-Time Monitoring

Advanced tracking systems give warehouses the power to monitor inventory and assets in real time. These systems use a mix of vision solutions, mobile technology, and integration platforms to keep operations running smoothly. Warehouses benefit from:

- Vision solutions that identify products, check for damage, and verify packaging, which boosts accuracy and productivity.

- Mobile technology platforms that capture data on the go, making workflows more flexible and efficient.

- Integration with warehouse management and ERP systems, which brings all tracking data together for better analytics.

- Real-time visibility into inventory location, status, and condition, allowing managers to act quickly.

- Automated processes for receiving, picking, put-away, and quality control, which reduce manual errors.

- Exception management that alerts staff to unusual situations for fast response.

- Dashboard reporting that tracks key performance indicators for ongoing monitoring.

IoT-based systems like ELPRO's LIBERO Gx provide continuous access to location and environmental conditions such as temperature, humidity, and shock. These features help protect sensitive products and support immediate decision-making. GPS and BLE technologies work together to offer seamless tracking both indoors and outdoors. AI-powered insights predict and prevent issues like theft or delays, while geofencing and tamper alerts improve security.

Inventory Control

Accurate inventory control remains a top priority for warehouse managers. Advanced tracking systems address common challenges such as human error, misplaced items, and theft. They use real-time tracking, barcode scanning, and RFID integration to automate data entry and keep stock information up to date. Regular audits and employee training further improve accuracy.

Key practices for better inventory control include:

- Using barcode scanning and RFID tags for real-time visibility and less shrinkage.

- Conducting frequent audits to catch discrepancies early and discourage theft.

- Training employees on the importance of inventory accuracy.

- Enhancing security with cameras and electronic tags.

- Integrating tracking systems with sales, purchasing, and warehouse operations for automated restocking.

| Aspect | Description | Impact |

|---|---|---|

| Real-Time Tracking | Instant visibility into inventory levels and movements | Improves accuracy and reduces errors |

| RFID Integration | Continuous monitoring of high-value items | Deters theft and increases accountability |

| Automated Alerts | Notifications for unauthorized item movements | Enables quick security responses |

| Analytics and Reporting | Insights into theft patterns and discrepancies | Helps tailor loss prevention strategies |

| Operational Efficiency | Automated stock counts | Saves time and reduces human errors |

These systems transform tracking data into actionable insights, helping warehouses optimize inventory, prevent losses, and improve operational efficiency. Automated alerts and analytics support proactive management, leading to lower shrinkage and higher profitability.

Warehouse of the Future

Intralogistics 4.0

The warehouse of the future stands as a model of efficiency and intelligence. Intralogistics 4.0 brings together automation, robotics, and digital tools to create a seamless environment. Companies use autonomous vehicles like AGVs and AMRs, connected through fast networks, to move goods quickly and safely. Operators rely on augmented reality tools and smart glasses to boost accuracy and safety. Warehouse management systems track every task and resource, making sure nothing gets missed.

| Defining Feature | Description | Impact on Warehouse Operations |

|---|---|---|

| Automation | Automated storage and handling equipment maximize space and productivity | Faster processing, less manual work, better space use |

| Cobots | Robots help with transport and order preparation | Improved efficiency and teamwork |

| Data Intelligence | Big data analytics monitor throughput and predict scenarios | Smarter decisions, more agility |

| Digitalization | IT systems and networks connect every part of the warehouse | Flexibility to adapt to market changes |

| Autonomous Vehicles | AGVs and AMRs handle internal transport | Safer, more efficient operations |

| Augmented Reality Tools | Visual aids support operators | Higher efficiency, better safety |

| WMS | Software controls and monitors all tasks | Better coordination and performance |

In the warehouse of the future, companies plan logistics across departments using special software. Automation handles goods movement, while cobots divide tasks between machines and people. E-commerce drives the need for fast fulfilment, so automated systems process small packages with speed and accuracy. These changes make the warehouse of the future smarter, safer, and more agile.

Smart Warehousing

Smart warehousing transforms the warehouse of the future into a responsive and flexible hub. Companies use AI, IoT, and robotics to manage inventory and fulfilment. IoT sensors in pallets and shelves give real-time data on inventory and equipment. RFID tags automate tracking, cutting errors in order fulfilment. AI analyzes data to improve warehouse layout and picking routes.

- Smart warehousing gives real-time inventory visibility, reducing stockouts and overstock.

- Robotics and automation speed up order processing, leading to faster fulfilment.

- Automation lowers labor costs and boosts productivity.

- AI and machine learning improve demand forecasting and predictive maintenance.

- Smart warehousing systems scale easily to meet changing market needs.

- Advanced analytics help managers spot bottlenecks and optimize workflows.

In the warehouse of the future, automation can cut labor costs by up to 40% and inventory carrying costs by 25%. Productivity may rise by 200%, making fulfilment faster and more reliable. Smart warehousing ensures the warehouse of the future can adapt to any challenge, keeping supply chains strong and responsive.

The warehouse of the future uses smart warehousing to deliver quick, accurate, and cost-effective fulfilment. Companies that invest in these solutions lead the way into the future of logistics.

Future of Intralogistics

Industry Trends

The future of intralogistics brings rapid change to warehouse and fulfilment operations. Companies see automation and robotics, especially autonomous mobile robots, as key drivers for efficiency. These robots now handle repetitive tasks, improve material flow, and reduce labor costs. Artificial intelligence and machine learning help companies make faster decisions and manage real-time material flow. Real-time data analytics and IoT technologies allow managers to monitor operations closely and respond quickly to issues.

Sustainability stands out as a major focus. Energy-efficient robots and eco-friendly practices help companies lower waste and reduce their carbon footprint. Blockchain technology improves traceability and transparency in supply chains, making it easier to track goods from production to delivery. Demographic shifts, such as an aging workforce, push companies to adopt new technologies to fill talent gaps. Regulatory changes and government incentives also encourage automation and green solutions.

Key intralogistics trends include:

- Growth of micro-fulfillment and micro fulfilment centres for faster, localized delivery.

- Increased use of AI and IoT for predictive analytics and process optimization.

- Expansion of digital transformation and data-driven decision-making.

- Focus on sustainability and energy efficiency in all fulfilment operations.

Asia-Pacific, especially China and India, emerges as a leading market for these innovations. Companies invest in research, partnerships, and regional expansion to stay ahead in the future of intralogistics.

Integration with Manufacturing

The integration of intralogistics with manufacturing shapes the future of intralogistics and fulfilment. Companies optimize factory layouts to reduce material flow distances and improve process consistency. Automated Guided Vehicles and Automated Storage and Retrieval Systems streamline material handling, boost order accuracy, and lower manual labor needs.

This integration brings several benefits:

- Minimizes inventory levels and operational costs.

- Improves employee safety and throughput.

- Increases traceability and accuracy in fulfilment.

- Enables real-time communication between warehouses and production lines.

Micro-fulfillment and micro fulfilment centres play a vital role in this future. These centres support flexible, rapid fulfilment by placing inventory closer to customers and production sites. As companies face shorter delivery times and higher demand for flexibility, automated intralogistics becomes essential for maintaining a competitive edge.

Companies that embrace these intralogistics trends and integrate advanced systems with manufacturing will lead the future of intralogistics and fulfilment.

Sustainability

Green Practices

Warehouses now focus on green practices to lower their environmental impact. Companies adopt a range of strategies to create more sustainable intralogistics solutions:

- Use energy-efficient lighting, such as LED fixtures, to cut electricity use.

- Install high-efficiency motors and energy management systems for better control.

- Add renewable energy sources like solar panels and wind turbines to warehouse facilities.

- Optimize transportation routes to reduce fuel consumption and carbon emissions.

- Switch to electric vehicles and automated guided vehicles for cleaner operations.

- Choose eco-friendly packaging materials to reduce waste.

- Implement automation technologies, including mobile robots, to boost efficiency and lower labor costs.

- Deploy smart manufacturing tools that use IoT and big data analytics for real-time monitoring of energy use and emissions.

- Design warehouse layouts that improve workflow and reduce unnecessary movement.

- Work with sustainable suppliers and use low-impact transportation methods.

The "Lean and Green" approach combines waste reduction with high operational efficiency. Digital tools like artificial intelligence, IoT, and blockchain help companies track and lower waste across the supply chain. Many organizations also train employees to support sustainability goals and build a culture of environmental awareness.

Companies that invest in green practices not only protect the environment but also improve their reputation and long-term resilience.

Energy Efficiency

Energy efficiency stands as a key goal in modern warehouses. Companies track and measure their progress using clear metrics:

| Measurable Outcome | Description | Why It Matters | How to Track / Goal |

|---|---|---|---|

| Energy Consumption per Sq Ft | Tracks kWh used per square foot over time | Shows efficiency of lighting and equipment | Use energy monitoring systems; reduce usage |

| Carbon Emissions (CO₂e) | Measures carbon footprint from operations | Important for compliance and sustainability | Calculate CO₂e from bills and logs; aim for neutrality |

| Waste Diversion Rate | Percentage of waste recycled or reused | Reduces landfill costs and meets regulations | Track waste streams; target 90% diversion rate |

| Material Handling Equipment Efficiency | Compares electric vs. fossil-fuel equipment | Impacts energy use and emissions | Phase out fossil-fuel equipment |

| Packaging Waste per Order | Amount of packaging waste per order | Lowers costs and meets consumer expectations | Track and reduce non-recyclable packaging |

Warehouses replace old lighting with LEDs, cutting energy use by up to 70%. Smart controls, like occupancy sensors, further reduce costs. Some companies use hydrogen fuel-cell forklifts for longer runtimes and zero local emissions. AI-based energy management systems help save 5–15% more energy by monitoring usage in real time. These upgrades often come with utility rebates and quick payback periods.

A case study at a major warehousing provider showed that measuring energy use and productivity across different modules helps companies find the best ways to improve. Higher automation does not always mean better sustainability, so tracking the right data supports smarter decisions.

Energy-efficient warehouses lower costs, meet regulations, and support a cleaner future.

Intralogistics innovations such as robotics, automation, and advanced tracking systems continue to transform warehouse efficiency. Companies that adapt to new technologies gain measurable benefits, including improved accuracy and profitability. To prepare for the future, logistics professionals should evaluate their facility’s readiness, pilot scalable solutions, and educate teams. Staying informed about trends like AI, IoT, and sustainable practices ensures a competitive edge. The future belongs to those who embrace change, invest in automation, and monitor emerging solutions shaping the warehouse of the future.

- Attend industry events and review case studies to identify future-ready strategies.

- Prioritize flexible, scalable automation for long-term success.

FAQ

What is intralogistics, and why does it matter for warehouses?

Intralogistics covers the movement and management of goods within a warehouse. Companies use intralogistics to improve speed, accuracy, and safety. Efficient intralogistics helps businesses meet customer demands and reduce costs.

How do automation and robotics improve warehouse operations?

Automation and robotics handle repetitive tasks. These technologies increase order speed, reduce mistakes, and lower labor costs. Workers can focus on more complex jobs, which boosts overall productivity.

What role does artificial intelligence play in modern warehouses?

Artificial intelligence analyzes data from warehouse systems. AI predicts demand, manages inventory, and spots problems early. Companies use AI to make smarter decisions and keep operations running smoothly.

How do warehouses become more sustainable?

Warehouses use energy-efficient lighting, electric vehicles, and smart systems to save energy. They recycle materials and choose eco-friendly packaging. These steps help companies lower their environmental impact and meet regulations.

Tip: Companies that invest in sustainability often see lower costs and a stronger reputation.

See Also

The Essential Advantages Of SaaS WMS In Modern Warehousing

How EDI Tracking Advances Are Enhancing Shipment Transparency

Top Three Methods Lean Logistics Improves Supply Chain Sustainability

Key Features That Make WarpDriven ERP Ideal For Smart Enterprises

Ways Top Brands Expand Successfully Using WarpDriven Distribution