3 Ways Lean Logistics Boosts Supply Chain Sustainability

You can strengthen your supply chain by using lean logistics to cut waste, improve efficiency, and boost collaboration. Recent studies show that lean logistics not only reduces material and energy waste but also shortens lead times and lowers emissions through smarter routing and lean inventory-to-sales ratios. By adopting lean supply chain management, you can minimize environmental impacts, increase cost savings, and build stronger partnerships for greater sustainability.

- Reduce waste and manage resources efficiently

- Improve economic performance and save costs

- Enhance collaboration and promote sustainable practices

Lean Logistics and Waste Reduction

Lean logistics helps you cut waste in every part of your supply chain. By focusing on eliminating waste, you can save materials, time, and energy. This approach supports lean supply chain management and leads to real cost savings and better efficiency.

Cutting Material Waste

You can reduce material waste by using lean logistics tools like just-in-time inventory and visual management. These tools help you avoid overproduction and excess stock. For example, MACtac redesigned its adhesive transportation process with flexible tanks and lean methods, saving over $750,000 and eliminating empty miles. Kenco Group used kanban replenishment and visual management to improve inventory flow and reduce expedited freight costs. Companies like Ryder System Inc. have cut product damage costs in half by finding the root causes of waste and fixing them.

Tip: Organize your warehouse with 5S methods. This can cut the time spent searching for parts from 45 minutes to just 10 minutes.

| Source of Material Waste | How Lean Logistics Addresses It |

|---|---|

| Overproduction | Just-in-time inventory reduces excess stock. |

| Waiting | Streamlined workflows minimize idle time. |

| Transportation | Optimized layouts cut unnecessary movement. |

| Defects | Quality checks and continuous improvement lower scrap. |

Saving Time and Energy

Lean logistics helps you save time and energy by streamlining every step. Just-in-time delivery means you get materials only when you need them, so you do not waste time or space. Kanban systems and value stream mapping help you spot and remove bottlenecks. Cross-docking lets you move products directly from inbound to outbound trucks, skipping storage and saving handling time. Route optimization tools help you plan the fastest delivery routes, cutting fuel use and travel time.

- DHL cut fuel use per shipment by up to 20% by using automation and lean logistics.

- Besam North America saved over 233,000 kWh each year with better energy management.

Process Optimization

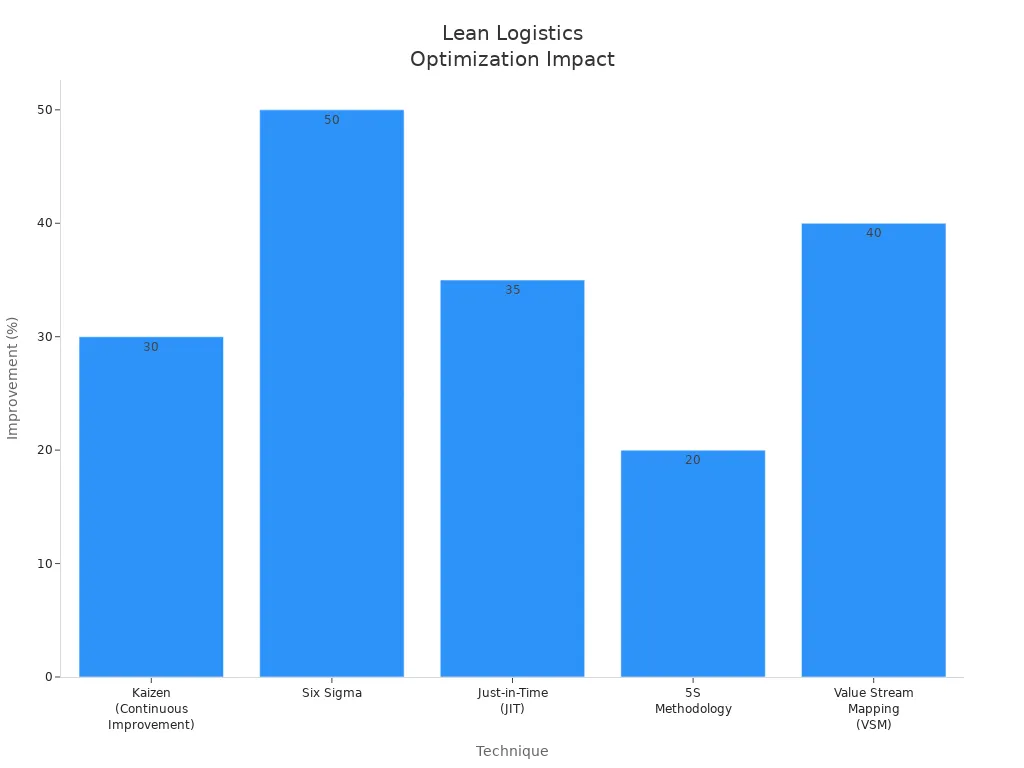

You can boost efficiency with process optimization techniques like continuous improvement, 5S, and just-in-time. These methods help you find and fix problems quickly. Kaizen workshops at Toyota increased efficiency by 30%. Six Sigma projects have cut defects by half in many businesses. Value stream mapping helps you see where delays happen and fix them fast.

Process optimization in lean logistics also lowers emissions and supports recycling. By focusing on continuous improvement, you make your supply chain more efficient and sustainable every day.

Efficient Transportation in Lean Supply Chain Management

Efficient transportation is a core part of lean supply chain management. When you focus on transportation, you can cut costs, save fuel, and reduce emissions. Lean logistics gives you tools to plan better routes, use vehicles more efficiently, and make smarter decisions every day.

Route Optimization

You can use route optimization to make every delivery faster and more efficient. Lean supply chain management relies on advanced software and real-time data to plan the shortest and safest routes. This approach helps you avoid traffic, reduce idle time, and use less fuel. For example, companies like UPS use routing software to save millions of miles and gallons of fuel each year. You can also track key performance indicators such as on-time delivery rates and fuel efficiency to keep improving your routes.

Tip: Use GPS tracking and telematics to monitor your fleet and adjust routes quickly when problems arise.

Best practices for route optimization include:

- Using dynamic route planning tools that adjust for traffic and weather

- Integrating route software with your supply chain management systems

- Training drivers to follow optimized routes and avoid delays

Lowering Emissions

Lean logistics helps you lower emissions by reducing unnecessary trips and making each mile count. Lean supply chain management encourages you to consolidate shipments and use full truckloads. This means fewer trips and less fuel burned. Transportation makes up a large part of supply chain emissions, sometimes up to 15%. By using lean logistics, you can cut these numbers. For example, load optimization and route consolidation both lower fuel use and emissions. Some companies even use electric or hybrid vehicles on optimized routes to further reduce their carbon footprint.

- Route optimization software can help you avoid congested areas and plan the most fuel-efficient paths.

- Real-time data analytics let you make quick changes to routes, saving fuel and cutting emissions.

Smart Load Planning

Smart load planning is another key part of lean supply chain management. You can maximize every trip by making sure vehicles are fully loaded both ways. This reduces empty miles and saves money. Lean logistics also helps you match the right vehicle to each load, considering size, weight, and delivery windows. You can use mobile apps and warehouse automation to align picking and packing with your load plans. This approach improves safety, reduces damage, and boosts customer satisfaction.

| Benefit of Smart Load Planning | How It Helps Your Supply Chain |

|---|---|

| Fewer trips | Lower fuel costs and emissions |

| Full truckloads | Higher value per trip |

| Real-time adjustments | Faster, more reliable delivery |

| Balanced loads | Safer transport, less damage |

When you use lean supply chain management, you make your transportation network stronger and more efficient. Lean logistics gives you the tools to plan better, act faster, and deliver more value with every mile.

Collaboration and Transparency

Lean logistics helps you build strong partnerships and create open communication across your supply chain. When you work closely with partners, you can solve problems faster and make better decisions. This teamwork leads to better supply chain performance and supports your sustainability goals.

Partner Communication

You can improve partner communication by using cross-functional teams and regular meetings. These teams bring together people from different departments and companies. They help everyone share ideas and spot problems early. Open and honest communication builds trust and makes it easier to reach shared goals.

- Use digital tools like supply chain management software and real-time data sharing platforms to keep everyone informed.

- Set clear goals with your partners and review progress together.

- Train your team on lean logistics principles so everyone understands how to reduce waste and improve efficiency.

- Celebrate successes and reward efforts to encourage ongoing improvement.

A food supply chain case showed that working with partners at every level helped overcome barriers like high costs and complex processes. By sharing information and working together, companies found new ways to save resources and improve results.

Supply Chain Visibility

You can boost supply chain visibility by using technology to track goods and share information in real time. Lean logistics relies on tools like GPS, IoT sensors, and cloud-based platforms. These tools let you see where products are, how they move, and if there are any delays.

| Technology Tool | Benefit for Supply Chain Management |

|---|---|

| Real-Time Visibility Platforms | Track products and shipments instantly |

| GPS and IoT Sensors | Monitor location and condition of goods |

| AI and Analytics | Predict demand and spot risks early |

| Warehouse Management Systems | Improve stock accuracy and order speed |

When you have better visibility, you can spot risks, avoid delays, and make sure your supply chain meets all rules and standards. This transparency helps you manage suppliers, reduce waste, and improve supply chain management.

Sustainable Decisions

Lean logistics gives you the tools to make smart, sustainable choices. You can use decision-making frameworks that balance cost, speed, and environmental impact. For example, you might choose suppliers who use renewable materials or switch to electric vehicles for deliveries.

Many companies use lean logistics to cut emissions, reduce packaging waste, and invest in green energy. Some switch to reusable packaging or install solar panels at warehouses. Others use digital systems to cut paper use and track progress on sustainability goals.

When you combine lean logistics with strong communication and visibility, you make better decisions for your business and the planet.

You can make your supply chain more sustainable by using lean logistics to reduce waste, improve transportation, and build strong partnerships. Lean logistics helps you cut costs, lower emissions, and boost efficiency by streamlining workflows and using smart technology.

- Optimize routes and inventory to avoid waste and save resources.

- Work closely with partners and use real-time tracking for better results.

- Explore resources from GENEDGE Alliance or the Lean Enterprise Institute to learn more.

Start small with lean logistics changes and watch your supply chain become greener and stronger.

FAQ

What is lean logistics?

Lean logistics means you remove waste from your supply chain. You focus on using resources wisely and making processes simple. You use tools like just-in-time delivery and 5S to save time, money, and energy.

How does lean logistics help the environment?

You help the environment by using fewer resources and cutting emissions. Lean logistics lets you plan better routes, use less fuel, and reduce waste. You also lower your carbon footprint by making smarter choices every day.

Can small businesses use lean logistics?

Yes, you can use lean logistics even if you run a small business. Start with simple steps like organizing your workspace or tracking inventory. Small changes can make a big difference in saving money and reducing waste.

What tools help you track supply chain performance?

You can use real-time tracking platforms, GPS, and warehouse management systems. These tools show you where your products are and help you spot problems fast. They also help you make better decisions for your supply chain.

See Also

Driving Business Expansion Through Outsourced Supply Chain Solutions

The Essential Advantages Of SaaS WMS For Modern Warehousing

Key Features That Differentiate WarpDriven ERP For Smart Enterprises

Ways Top Brands Expand Using WarpDriven Distribution Technology

The Role Of Distribution Management In Driving Worldwide Success