Why Mis Shipments Hurt Your Financial Impact More Than You Think

Mis-shipments drain your profits and weaken your bottom line far more than you might expect. Every incorrect order or delayed delivery can create a chain reaction of costs that quickly add up. In ecommerce, a single misshipment not only increases your immediate cost but also puts your customer relationships at risk. Customers remember when shipments arrive late or wrong, and repeated order errors push them to choose other suppliers. A 2023 Statista study shows that 45% of online shoppers base repeat purchases on reliable delivery, so the financial impact of mis-shipments extends beyond refunds or reshipping. Ecommerce brands that ignore these issues may see damaged reputations and lost contracts, which hit the bottom line hard.

Financial Impact of Mis-Shipments

Direct Costs

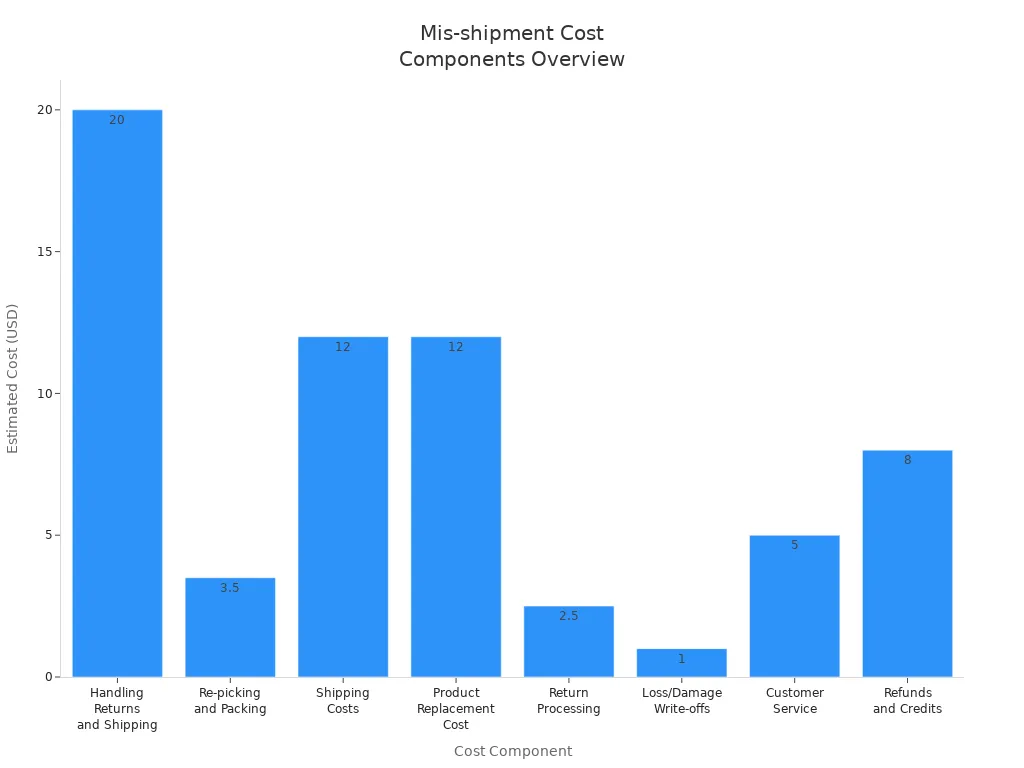

You face direct costs every time a misshipment occurs in your ecommerce operation. These costs hit your bottom line immediately and can quickly add up. When you send the wrong item or ship to the wrong address, you must pay for return shipping, reshipping, and extra labor. Each step in correcting the error increases your expenses.

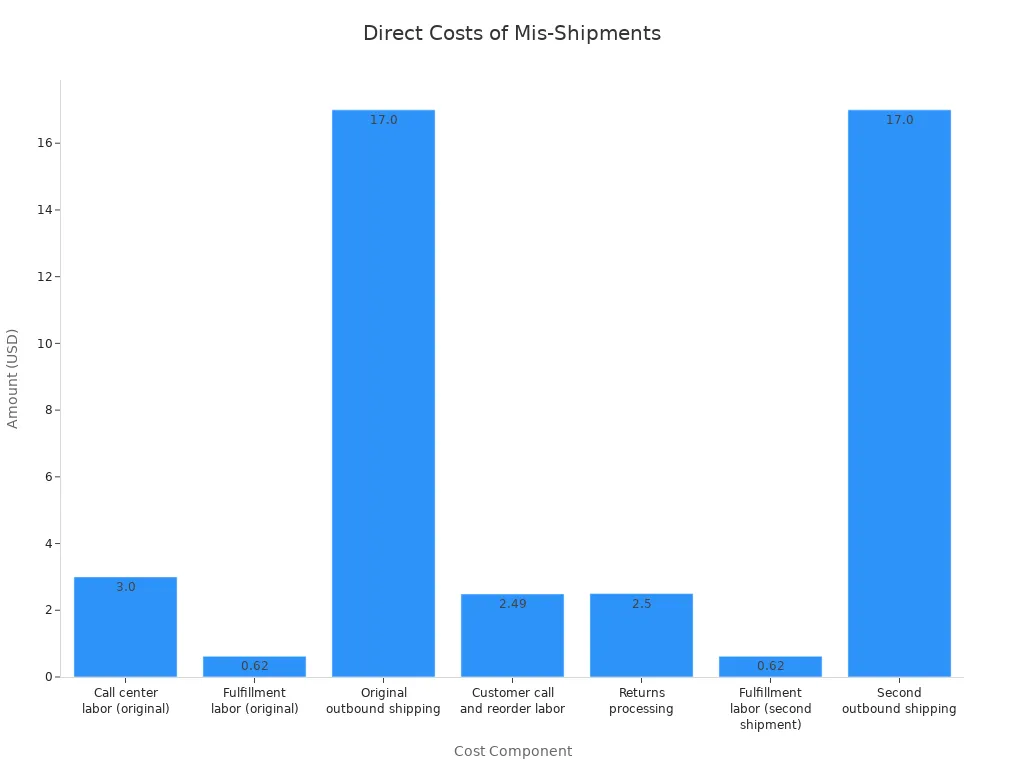

Here is a breakdown of the most common direct costs you might encounter:

| Cost Component | Amount (USD) |

|---|---|

| Call center labor (original) | 3.00 |

| Fulfillment labor (original) | 0.62 |

| Original outbound shipping | 17.00 |

| Customer call and reorder labor | 2.49 |

| Returns processing | 2.50 |

| Fulfillment labor (second shipment) | 0.62 |

| Second outbound shipping | 17.00 |

| Total direct cost per error | 43.23 |

You pay for return shipping when customers refuse or return packages due to mistakes. If you need to resend the order, you pay for reshipping fees and sometimes restocking. These costs do not include the time your team spends on customer service calls or investigating the error. In ecommerce, these direct costs can multiply fast, especially during peak seasons.

According to a Honeywell study, companies report about 134 mispicks per week. This leads to an annual cost of $400,000 from these errors. The average mis-shipment costs about $100 when you add up all the expenses. This number shows how much order mistakes can hurt your financial impact, especially if you run a busy fulfillment center.

Indirect Costs

Indirect costs from mis-shipments often go unnoticed, but they can damage your business even more than direct expenses. When you make a mistake with an order, you risk losing customer trust and future sales. Many customers will not give you a second chance.

- Customer dissatisfaction: One in five customers will never shop with your brand again after a single error.

- Loss of future sales: Two-thirds of customers switch to another brand after a poor experience, which lowers your customer lifetime value.

- Bad reviews: Negative feedback can drop your ratings and make it harder for new customers to trust your ecommerce business. A McKinsey study shows that higher star ratings lead to more sales.

- Increased customer acquisition spending: When you lose customers, you must spend more on marketing to replace them.

- Higher insurance premiums and extra personnel costs: Handling returns and replacements increases your overhead.

- Supply chain disruptions: Misshipments can cause delays, missed deadlines, and even product recalls.

- Reputation damage: Repeated mis-shipments make your brand look unreliable and can push customers to your competitors.

- Lower employee morale: Your team may feel stressed and frustrated when dealing with frequent errors and complaints.

Note: Indirect costs can last much longer than direct costs. They affect your reputation, your team, and your ability to grow your ecommerce business.

You must consider both direct and indirect costs to understand the true financial impact of mis-shipments. If you ignore these hidden expenses, you risk losing profits, customers, and your place in the market.

Misshipment Causes

Inventory Errors

You face inventory errors when your stock records do not match what you actually have in your warehouse. This mismatch often leads to a misshipment. If your team picks the wrong items or the wrong quantity, your customers receive a wrong order. These mistakes happen for many reasons, but the most common causes of misshipments include incorrect order picking, faulty inventory records, and mislabeled packages.

Here are some frequent inventory-related issues that impact your order fulfillment process:

- Incorrect order picking, such as grabbing a size M shirt instead of size L.

- Faulty inventory records, which cause you to ship items that are out of stock.

- Mislabeled packages, leading to deliveries to the wrong customers.

- Poorly organized warehouses, making it hard to find the right products quickly.

Tip: Regular inventory checks and clear labeling improve accuracy and reduce the risk of sending wrong items.

A well-organized warehouse and accurate stock data help you avoid costly fulfillment errors. When you invest in better inventory management, you protect your business from the ripple effects of a misshipment.

Process Failures

Process failures in your fulfillment operation can also cause misshipments. These failures often happen when your team does not follow clear steps or when your systems lack proper checks. You might see errors like picking the wrong item from the right location or substituting products when instructions are unclear.

Common process failures include:

- Picking the wrong items due to inventory replenishment issues.

- Adding the wrong quantity, especially in bulk orders.

- Human errors from fatigue or poor lighting.

- Lack of strong inventory accuracy controls.

- Unorganized shipping stations that increase mistakes.

| Cause | Explanation |

|---|---|

| Inefficient inventory management | Skipping regular checks leads to inaccurate stock and delayed orders. |

| Lack of communication between teams | Misinterpreted information increases shipment errors and delays. |

| Insufficient software capabilities | Weak systems limit validation and allow costly mistakes. |

You can reduce misshipment causes by improving your order fulfillment process. Use capable software and validation scanning to catch errors before they reach your customers. When you focus on process accuracy, you lower the risk of sending a wrong order and protect your reputation.

Ripple Effects

Operational Disruptions

When you experience mis-shipments, your entire operation feels the impact. Delays create backlogs in your warehouse and distribution center. You face higher operational costs because you must reroute shipments and issue refunds. Your customer service team handles more complaints, which increases their workload and slows down response times. These disruptions do not stay isolated. They often affect other orders and reduce your overall efficiency.

- Delays in processing create warehouse backlogs.

- Rerouting shipments and issuing refunds increase operational costs.

- Customer service teams handle more complaints and investigations.

- Disruptions spread to other orders, lowering operational efficiency.

- Refunds, discounts, and reshipping costs lead to financial loss.

- Customer dissatisfaction grows, risking future sales and damaging your reputation.

If your warehouse management system is ineffective, you may see incorrect inventory counts and misdirected shipments. Order backlogs can build up, especially during demand surges. Labor shortages make these problems worse. These issues can result in failed deliveries, lost customers, and significant damage to your bottom line.

Note: Operational disruptions from mis-shipments can quickly erode your bottom line and make it harder to recover.

Compounding Losses

Mis-shipments do not just cause one-time problems. They create a chain reaction that compounds your losses over time. When critical raw materials arrive late or get lost, your production lines may stop. This downtime leads to missed production targets and increased costs. Your supplier relationships become strained, and your operations lose stability.

- Lost revenue occurs when customers cannot buy due to stockouts or delays.

- Each lost sale means missed cross-selling and upselling opportunities.

- Reduced sales volume increases your cost per sale, hurting your bottom line.

- Customer lifetime value drops as repeat business and loyalty decline.

- Your brand reputation suffers, leading to negative reviews and lost potential customers.

- Market share shrinks as competitors meet the demand you cannot fulfill.

Supply chain disruptions from mis-shipments also lead to inventory mismanagement. You may face higher storage and handling expenses, increased insurance costs, and more administrative overhead. Over time, these hidden costs add up and weaken your bottom line. Addressing these challenges requires investment in technology, better communication, and strategic inventory management.

Mis-Shipments to Customers

Customer Experience

When you send mis-shipments to customers, you risk damaging the entire shopping experience. A wrong order can frustrate your customers and make them feel undervalued. Many customers expect fast, accurate delivery and clear communication. If you fail to meet these expectations, you lose their trust and loyalty.

- Customers respond poorly to generic or impersonal messages after a mistake. They want you to address their concerns directly.

- Returns and negative post-purchase experiences, such as mis-shipments to customers, increase the chance that customers will stop buying from you.

- Lack of personalized communication means you miss chances to upsell or cross-sell, which lowers repeat purchase rates.

- Every return not only costs you money in logistics but also reduces customer lifetime value.

Note: Personalized engagement helps you keep customer satisfaction high, even after a mis-shipments to customers. Using data to understand customer behavior lets you tailor your response and win back trust.

You can improve customer satisfaction by offering quick solutions, clear updates, and rewards for loyal customers. When you focus on each customer’s needs, you build stronger relationships and encourage repeat business.

Brand Reputation

Mis-shipments to customers do more than hurt individual relationships—they can damage your brand reputation across the market. Many shoppers see delivery problems as a sign that your business is unreliable. If you do not manage shipping visibility and communication, you risk losing customer satisfaction and loyalty.

- 75% of shoppers say last-mile delivery issues, such as late or missing packages, are their biggest frustration.

- 16% of consumers will stop shopping with you after just one incorrect delivery.

- 69% are less likely to return if you do not deliver within two days of the promised date.

Negative online reviews about mis-shipments can quickly spread. Half of all consumers trust online reviews as much as personal recommendations. When customers read about wrong orders or late deliveries, they see your brand as risky. This perception leads to fewer sales and lost opportunities.

Callout: Negative reviews from mis-shipments to customers act as social proof. They increase the perceived risk of buying from you and can drive away new customers.

You protect your brand reputation by delivering on promises, communicating clearly, and responding quickly to problems. Strong customer satisfaction leads to positive reviews and long-term loyalty.

Preventing Mis-Shipments

Process Improvements

You can prevent misshipments by making your warehouse processes more reliable and efficient. Start by labeling all stock locations with clear zone, aisle, bay, level, and position markers. This step helps your team find products quickly and reduces picking mistakes. Avoid placing multiple SKUs in the same bin. This simple change speeds up picking and helps prevent misshipments.

Use barcode labeling and scanning at every stage—receiving, put-away, picking, and packing. These steps reduce errors and improve order accuracy. Regularly review your operations and customer service reports. When you spot a pattern of mistakes, take action right away.

Tip: Train your staff often. Teach them how to use inventory tools and handle products with care. Companies like Amazon have shown that combining staff training with automation can reduce errors and improve accuracy.

Here are some proven ways to prevent misshipments:

- Organize your warehouse layout for easy workflow.

- Use packaging checklists and weight verification systems.

- Analyze KPIs like picking accuracy and backorder rates.

- Hold regular process audits and update your standard operating procedures.

Technology Solutions

Technology gives you powerful tools to prevent misshipments and reduce errors. A Warehouse Management System (WMS) tracks inventory in real time and automates order processing. Barcode scanning during picking and packing checks each item, making sure you send the right products.

Order Management Systems (OMS) connect with your WMS to centralize order data and automate error checks. Many businesses use mobile picking apps, RF devices, and pick-to-light systems to boost accuracy and speed. Automation, such as AI-powered barcode scanning, can prevent mis-shipments by catching mistakes that humans might miss.

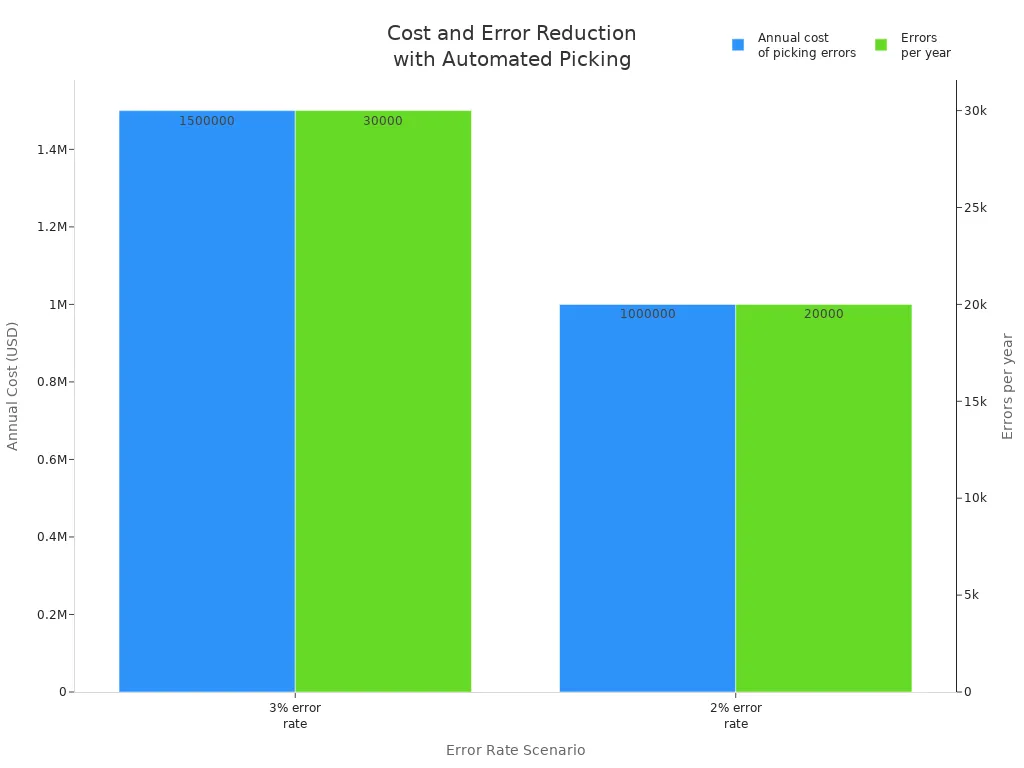

A 1% improvement in picking accuracy can save up to $500,000 per year in a high-volume operation. Automated picking systems also increase productivity and help you maintain high order accuracy. For small businesses, using integrated shipping solutions and automating inventory checks can prevent misshipments without adding much cost.

Note: The right mix of process improvements and technology will help you reduce errors, protect your reputation, and keep your customers happy.

You often overlook the true cost of mis-shipments, but both direct and hidden expenses can erode your profits and damage your relationship with customers. Proactive prevention, such as real-time monitoring and structured protocols, helps you reduce disruptions and support long-term financial stability.

- Assess your current mis-shipment rates by analyzing costs like returns, shipping, and customer service.

- Upgrade your systems with barcode scanning and smart warehouse management to minimize future errors.

Review your processes now to protect your customers and secure your business for the future.

FAQ

What is a mis-shipment?

A mis-shipment happens when you send the wrong item, quantity, or shipment to a customer. This mistake can include shipping to the wrong address or sending damaged goods.

How do mis-shipments affect your profits?

Mis-shipments increase your costs through returns, reshipping, and extra labor. You also lose future sales when customers stop trusting your brand. These errors can quickly reduce your profits.

What steps can you take to prevent mis-shipments?

Tip: Use barcode scanning, organize your warehouse, and train your staff often. These steps help you catch mistakes before they reach your customers.

Can technology help reduce mis-shipments?

Yes. Warehouse Management Systems (WMS) and automated picking tools help you track inventory and orders in real time. These systems lower error rates and improve order accuracy.

See Also

Driving Business Expansion Through Outsourced Supply Chain Solutions

The Essential Advantages Of SaaS WMS For Modern Warehousing

Important 2025 Amazon FBM Fee Updates Every Seller Should Know

Key Features That Differentiate WarpDriven ERP For Smart Enterprises

The Role Of Distribution Management In Driving Worldwide Business Success