Can Overflow Warehousing Sustain E-commerce Growth?

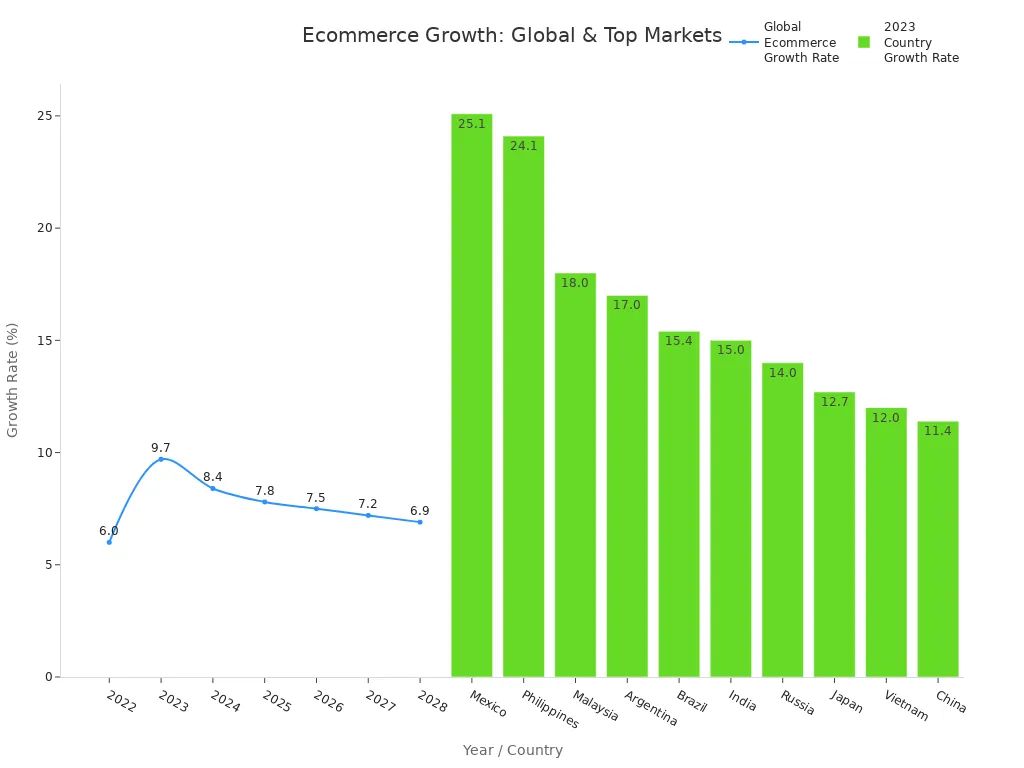

Overflow warehousing plays a critical role in sustaining e-commerce growth, providing the flexibility that modern retailers need. Global ecommerce sales reached $4.8 trillion in 2023, with projections nearing $9 trillion by 2032. This rapid growth, shown in the chart below, creates new challenges for inventory and fulfillment.

Retailers turn to overflow warehousing as a strategy to support business growth, manage sudden surges, and implement effective growth initiatives in ecommerce.

Overflow Warehousing Basics

What Is Overflow Warehousing

Overflow warehousing in ecommerce means using temporary and scalable solutions to manage excess inventory. When a business faces more products than its main warehouse can hold, it uses overflow storage to keep extra items safe and organized. This often happens during busy seasons or when demand spikes. Companies do not need to build new commercial warehousing facilities. Instead, they partner with third-party providers who offer flexible warehouse space. These providers set up special areas for overflow storage, keeping slow-moving or surplus inventory separate from the main stock. This method prevents overcrowding, reduces safety risks, and keeps operations running smoothly. Overflow warehousing helps businesses avoid the high costs of expanding permanent warehouse space. It also improves inventory control and keeps the main warehouse efficient.

Note: Overflow warehousing is a cost-effective way for ecommerce businesses to handle excess inventory without long-term commitments.

Why Ecommerce Businesses Use It

Ecommerce businesses often face sudden changes in inventory levels. Seasonal sales, inaccurate forecasts, supply chain problems, and bulk buying can all lead to excess inventory. When the main warehouse gets too full, it causes delays, mistakes, and even product damage. Overflow warehousing solves these problems by offering extra storage during peak times. Companies can move slow-selling items to overflow storage, making room for fast-selling products in their main commercial warehousing. This approach gives ecommerce businesses more control over inventory and helps them respond quickly to changes in demand.

- Main reasons ecommerce businesses use overflow warehousing:

- Seasonal demand surges create excess inventory.

- Inaccurate forecasting leads to unexpected inventory overflow.

- Supply chain disruptions cause sudden increases in stock.

- Bulk purchasing fills up warehouse space quickly.

- Overflow storage prevents operational problems and keeps order fulfillment fast.

- Businesses pay only for the warehouse space they need, saving money.

Third-party logistics providers and advanced warehouse management systems help ecommerce businesses find overflow storage quickly. These solutions use real-time tracking and smart tools to balance inventory across multiple commercial warehousing locations. This keeps operations efficient and costs low.

Benefits for E-commerce Growth

Flexibility and Scalability

Ecommerce faces constant changes in sales patterns, inventory levels, and customer expectations. Overflow warehousing gives ecommerce businesses the flexibility to handle these changes without building new facilities. Companies can use overflow storage to manage excess inventory during seasonal peaks or unexpected demand surges. This approach helps maintain operational efficiency and supports e-commerce growth.

- Third-party logistics providers offer flexible warehouse space and labor. Businesses can scale up or down as needed, avoiding the fixed costs of owning commercial warehousing.

- Nationwide fulfillment networks place inventory closer to customers. This reduces shipping times and costs, which improves customer satisfaction.

- Advanced technology, such as warehouse management systems, gives real-time inventory visibility. This helps ecommerce businesses respond quickly to changes in demand.

- Multi-warehouse strategies lower shipping times, cut costs, and diversify risk. Companies can handle rapid growth and disruptions more easily.

- Automation and technology boost operational efficiency. Businesses can process more orders and manage inventory surges without hiring extra staff.

A handcrafted furniture company once struggled with errors and shipping delays as online sales grew. By partnering with a commercial warehousing provider, the company gained access to real-time inventory tracking and faster shipping. This partnership improved customer satisfaction and allowed the company to focus on product innovation. Overflow warehousing supported their scalable growth and operational flexibility.

The on-demand warehousing market is growing fast. Over 60% of businesses now use or consider flexible warehousing to optimize logistics. The e-commerce and retail sector leads this trend, showing strong adoption of overflow storage as a strategy for handling excess inventory and supporting e-commerce growth.

Multi-channel Fulfillment

Ecommerce businesses often sell products on many platforms, such as their own websites, online marketplaces, and physical stores. Overflow warehousing supports multi-channel fulfillment by making it easier to manage inventory across all these channels. This approach keeps order fulfillment fast and accurate, even when sales increase suddenly.

- Overflow warehousing provides temporary storage outside the main warehouse. Ecommerce businesses can manage seasonal peaks and unexpected demand surges without long-term commitments.

- Fulfillment centers use advanced technology to connect with multiple sales channels. Real-time inventory tracking reduces errors and speeds up picking, packing, and shipping.

- Customizable services, like pick-and-pack and cross-docking, help manage seasonal inventory spikes.

- Outsourcing fulfillment lets businesses focus on marketing and product development while experts handle logistics.

- Strategic warehouse locations near customers or shipping hubs reduce delivery times and costs.

Amazon Multi-Channel Fulfillment shows how overflow warehousing supports multi-channel strategies. Sellers use Amazon’s network to fulfill orders from platforms like Shopify, WooCommerce, and eBay. This system simplifies warehousing, shipping, and order tracking, making e-commerce fulfillment more scalable and reliable.

| Company | Key Outcome | Benefit to Multi-Channel Fulfillment Strategy |

|---|---|---|

| Ace Hardware | Saved $30K per day in port fees using on-demand warehousing for overflow | Flexible capacity management, cost savings during unexpected surges |

| Walmart | Added 3 fulfillment centers, 99.9% ship-on-time rate during peak season | Managed peak demand, increased throughput, improved customer service |

| Lull | Reduced delivery times by 51%, cut FedEx shipping costs by 30% | Positioned inventory closer to customers, faster delivery, lower costs |

| Digital Brand | Expanded SKUs from 6 to 500, grew from 1 to 12 warehouses | Scalable fulfillment network, tested new markets and strategies |

Warehouse management systems, inventory management systems, and order management systems all work together to centralize order processing. Automation and robotics increase speed and reduce labor costs. Integration with ecommerce platforms ensures accurate inventory updates and synchronized order statuses across channels. These tools help ecommerce businesses fulfill orders from multiple sales channels efficiently.

Cost and Efficiency

Overflow warehousing offers significant cost savings and boosts operational efficiency for ecommerce businesses. Traditional commercial warehousing often requires long-term leases and fixed costs, even when warehouse space goes unused. In contrast, on-demand warehousing uses a pay-as-you-go model. Businesses only pay for the storage and services they use, which aligns expenses with sales cycles and reduces financial risk.

- On-demand warehousing eliminates fixed operating costs like leases, utilities, and maintenance fees.

- Fractional warehousing allows businesses to scale warehouse space up or down quickly. This avoids year-round committed space costs and reduces upfront capital investment.

- Shared warehouse resources lower costs through volume discounts and reduced overhead.

- Flexible contracts reduce risks tied to long-term leases. Companies can adjust storage needs as sales and inventory levels change.

- Placing inventory closer to demand centers cuts shipping and operational costs.

Ecommerce businesses using overflow warehousing often achieve faster delivery and higher customer satisfaction than those relying on traditional warehousing. Fulfillment centers focus on picking, packing, shipping, and returns management. They use advanced technology for real-time inventory and shipping automation. This leads to fast, accurate order fulfillment and supports e-commerce growth.

Tip: Efficient warehouse design, automation tools, and tidy operations all help improve order accuracy and speed. These factors directly boost customer satisfaction and support ecommerce growth.

| Aspect | Overflow Warehousing (Fulfillment Centers) | Traditional Warehousing |

|---|---|---|

| Primary Function | Order fulfillment, picking, packing, shipping, returns | Long-term storage, bulk inventory handling |

| Delivery Speed | Fast, often same-day or next-day | Slower, longer lead times |

| Customer Focus | High, branded packaging, tracking updates | Minimal |

| Technology Use | Advanced systems, real-time inventory, automation | Basic, manual operations |

| Inventory Turnover | High, supports rapid fulfillment | Low, focused on storage |

| Location | Near population centers, fast delivery | Rural, less accessible, lower cost |

| Scalability | Flexible scaling during peak demand | Limited, slower to adapt |

Overflow warehousing converts fixed costs into variable costs. This enables leaner operations and better resource allocation. Ecommerce businesses gain resilience against disruptions and can adapt quickly to changing market conditions. By using overflow storage and commercial warehousing strategically, companies support e-commerce growth, manage excess inventory, and maintain high operational efficiency.

Challenges for Ecommerce Business

Costs and Complexity

Ecommerce businesses face many challenges when using overflow warehousing to manage excess inventory. Costs can rise quickly. Overcrowded warehouses often lead to higher workplace injuries and delayed orders. Labor costs make up a large part of warehouse expenses. Recent increases in minimum wage and labor shortages have pushed these costs even higher. For example, California saw its minimum wage rise from $10 to $15 between 2017 and 2023. This change caused warehouse expenses to grow by almost 7% each year.

Other factors add to the complexity. Poor warehouse design and weak inventory forecasting waste space and create more excess inventory. Fluctuating seasonal demand makes planning difficult. Tariff changes force businesses to stockpile inventory, which increases storage needs and costs. On-demand warehousing offers flexibility but usually comes with higher unit costs. Advanced technology, such as Warehouse Management Systems, can help, but these tools require big investments and time to set up.

Note: Balancing cost and service levels becomes difficult as ecommerce businesses try to keep up with rapid changes and disruptions.

Inventory Management

Managing excess inventory across multiple locations creates new problems. Ecommerce businesses must standardize and digitize their inventory management processes to keep operations smooth. Many use barcode scanning, RFID, and automated data capture for real-time inventory visibility. These tools help reduce errors and improve accuracy. Data analytics and smart algorithms help forecast demand, so businesses can avoid both shortages and too much excess inventory.

Warehouse layouts need careful planning to make inventory easy to find and move. Reverse logistics, such as handling returns, adds another layer of complexity. Many ecommerce businesses partner with third-party logistics providers. These partners use advanced inventory management systems and data-driven decisions to track inventory across several locations. This approach helps reduce disruptions, improve resilience, and keep shipping times short.

Integration Issues

Integrating overflow warehousing with existing systems often brings technical challenges. Ecommerce businesses must follow a clear plan to avoid disruptions. The process usually includes:

- Creating a step-by-step deployment plan with a timeline.

- Training users and sharing go-live dates.

- Migrating data carefully to prevent errors.

- Running old and new systems together at first to spot problems.

- Offering ongoing support to fix issues quickly.

- Monitoring system performance and collecting feedback.

- Auditing data and updating systems for security and stability.

- Aligning business processes with new systems.

- Providing regular training and encouraging user involvement.

These steps help maintain resilience and reduce disruptions during the transition. Ongoing support and user engagement ensure that the new system works well and supports efficient inventory management, even when excess inventory and supply chain disruptions occur.

Comparing Warehousing Solutions

Overflow vs. Dedicated Warehousing

E-commerce businesses often choose between overflow warehousing and dedicated warehousing. Overflow warehousing works best for temporary storage needs. Companies use it during seasonal spikes or short-term projects. This model offers pay-as-you-go pricing and quick setup. Businesses do not need to sign long-term contracts. They can scale space up or down as needed. However, overflow warehousing gives less control over inventory and may face space shortages during busy times.

Dedicated warehousing, also called contract or private warehousing, suits companies with steady, high-volume storage needs. These businesses sign fixed-term agreements, often lasting several years. Dedicated warehousing provides full control over operations, layout, and security. It allows for custom solutions and stable, predictable pricing. However, it requires higher upfront costs and long-term commitments. Scaling up means renegotiating contracts or finding new facilities.

| Aspect | Dedicated Warehousing | Overflow Warehousing |

|---|---|---|

| Cost | High, with fixed long-term contracts | Lower, pay-as-you-go, flexible |

| Flexibility | Low, fixed space and setup | High, easy to scale up or down |

| Scalability | Limited during contract term | Easily scalable for short-term needs |

Many e-commerce businesses use both models. They store core inventory in dedicated commercial warehousing and use overflow warehousing for extra stock during busy periods.

On-demand and Flexible Options

On-demand warehousing gives e-commerce businesses even more flexibility. This model lets companies rent space only when needed. They avoid long-term leases and large upfront investments. On-demand warehousing supports fluctuating demand, seasonal peaks, and short-term projects. It helps businesses expand into new markets by renting space in strategic locations.

Overflow warehousing is a specific use case within on-demand warehousing. Companies use it to store excess inventory during sudden surges or supply chain disruptions. On-demand warehousing covers a wider range of needs, such as e-commerce fulfillment and retail distribution. It allows rapid scaling of storage and fulfillment capacity. This approach improves delivery times and reduces shipping costs.

On-demand warehousing also benefits the environment. Companies use space more efficiently and avoid running underused warehouses. Storing goods closer to customers lowers transportation distances and reduces emissions. This model supports a greener supply chain compared to traditional commercial warehousing.

Tip: E-commerce businesses often start with flexible warehousing. As their needs grow, they may move to dedicated commercial warehousing for more control and efficiency.

Best Practices for Fulfillment

Technology and Data

Technology helps ecommerce businesses manage overflow warehousing more efficiently. Order Management Systems (OMS) and Warehouse Management Systems (WMS) connect with ecommerce platforms to improve order processing and inventory tracking. These systems reduce errors and help teams see inventory levels in real time. Automation tools, such as robotic picking systems and conveyor belts, speed up picking and packing. Data analytics help managers spot problems, optimize storage space, and prevent congestion. On-demand warehousing platforms let businesses access many fulfillment centers through one system. This approach shortens delivery times and helps companies respond quickly to changes in demand. Security remains important. Providers use encryption, access controls, and regular audits to protect sensitive data and keep inventory information safe.

Tip: Use technology to automate tracking, improve accuracy, and keep inventory data up to date across all sales channels.

Choosing Partners

Selecting the right partners is key for a successful overflow warehousing strategy. Ecommerce businesses should first assess their needs, such as order volume changes and product types. They should choose partners who can scale up or down during busy seasons. Technology integration matters. Partners must offer real-time tracking and easy connections to ecommerce systems. Regional expertise helps optimize shipping routes and reduce delays. Good customer service ensures quick problem-solving. Businesses should also check warehouse facilities for special needs, like temperature control. Strong partners support returns management and offer value-added services, such as custom packaging. Clear communication and regular training help teams work together smoothly.

- Assess business needs and growth plans.

- Check partner experience and warehouse capabilities.

- Ensure technology integration and real-time tracking.

- Review customer service and communication quality.

- Confirm support for returns and special handling.

- Match warehouse locations to target markets.

- Understand pricing and extra costs.

Inventory Optimization

Proper inventory management prevents common mistakes in overflow warehousing. Businesses should use real-time tracking to avoid overstocking and stockouts. A well-designed warehouse layout reduces picking times and labor costs. Automation tools, like barcode scanners, improve accuracy. Regular staff training lowers errors and keeps operations safe. Seasonal planning with partners helps manage busy periods. Clear communication with logistics providers avoids confusion and delays. Companies should also set up dedicated zones for returns to streamline reverse logistics. Safety protocols protect workers and prevent disruptions.

- Use advanced WMS for live inventory updates.

- Analyze data to make better stocking decisions.

- Plan for seasonal peaks with flexible storage.

- Train staff and enforce safety rules.

- Automate processes to reduce manual errors.

Note: Optimizing inventory and warehouse processes helps ecommerce businesses save money, improve order accuracy, and keep customers happy.

Overflow warehousing helps ecommerce businesses manage inventory surges, lower costs, and improve delivery speed. Key takeaways include:

- On-demand warehousing supports ecommerce growth by offering flexible storage and faster fulfillment.

- Technology and trusted partners make scaling easier for startups and large companies. Ecommerce leaders should review their needs, costs, and system integration before choosing overflow solutions. Looking ahead, trends like automation, hyper-local fulfillment, and data-driven planning will shape the future of ecommerce warehousing.

FAQ

What is overflow warehousing?

Overflow warehousing gives businesses extra storage space when their main warehouse gets full. Companies use it during busy times or when they have more products than usual. This helps them keep operations running smoothly.

How does overflow warehousing help e-commerce businesses?

Overflow warehousing lets e-commerce companies store extra inventory during sales peaks. This prevents delays and mistakes. It also helps them fill orders faster and keep customers happy.

Is overflow warehousing expensive?

Costs depend on how much space a business needs and for how long. Many providers offer pay-as-you-go pricing. This means companies only pay for the space they use, which can save money.

What technology supports overflow warehousing?

Warehouse Management Systems (WMS) and Order Management Systems (OMS) help track inventory in real time. These tools reduce errors and make it easier to manage products across different locations.

How should a business choose an overflow warehousing partner?

A business should look for partners with strong technology, good customer service, and flexible storage options. Checking reviews and asking about experience with similar products can help find the right fit.

See Also

The Essential Advantages Of SaaS WMS In Modern Warehousing

How Intralogistics Advances Are Revolutionizing Warehouse Operations

The Role Of Micro Fulfillment Centers In E-Commerce Expansion

Strategies To Secure Long-Term Success In B2B Fulfillment

Maximizing Online Retail Efficiency Through Poly Bagging Solutions