Predictive Maintenance: The Future of Sewing is Here

Predictive maintenance is a proactive maintenance strategy for Industry 4.0. You use IoT sensors for real-time monitoring of your industrial equipment. This IoT automation sends real-time data to predict when your equipment needs service. This predictive approach boosts efficiency and prevents unplanned downtime. Industry 4.0 and IoT make this intelligent maintenance possible.

Forget old methods. Reactive maintenance fixes things after they break. Preventive maintenance schedules service you may not need. This Industry 4.0 IoT approach saves you from costly downtime.

This is a practical solution for modern smart factories. The real-time data from IoT sensors helps you extend the life of your machines. This Industry 4.0 automation provides real-time efficiency.

How IoT Enables Predictive Maintenance

The Internet of Things (IoT) is the engine that drives predictive maintenance. It creates a digital link between your physical sewing machines and powerful data analytics software. This connection turns your factory floor into a source of valuable, real-time information. This automation is a cornerstone of Industry 4.0, transforming how you manage your equipment. The entire process relies on a flow of information powered by IoT.

The Role of Smart Sensors

Think of sensors as the eyes and ears of your sewing machines. These small IoT devices attach to critical components. They perform real-time monitoring of the machine's health. You gain a constant stream of operational data. This real-time data is essential for the Industry 4.0 approach to maintenance.

Several types of sensors work together to build a complete picture:

- Vibration Sensors: These detect unusual shaking or irregular movements in motors and moving parts. A change in vibration can signal bearing wear or misalignment.

- Thermal Sensors: You use these sensors to watch for overheating. An increase in temperature often points to friction or electrical problems before a motor fails.

- Acoustic Sensors: These listen for changes in the machine's sound. A new grinding or whining noise can indicate a developing mechanical issue.

- Power Consumption Monitors: These track how much electricity a machine uses. A sudden spike in power draw can mean a motor is working too hard.

A Deeper Look at Thermal Sensors Thermal sensors are embedded in motor windings to give you early warnings. For these sensors to work, you must connect them to a monitoring device like a Variable Frequency Drive (VFD). The VFD reads the sensor's output. When a motor gets too hot, the VFD can trigger a fault and shut it down to cool off. Three common types of sensors you will encounter are:

- PTC Thermistor Sensors: These act like a switch. They show a huge jump in resistance at a specific temperature, triggering a shutdown to prevent damage.

- KTY Temperature Sensors: These provide a more linear reading. Their accuracy allows you to set warning levels before a full shutdown is necessary.

- PT1000 Sensors: These use platinum for highly accurate and repeatable temperature data. You get precise real-time data for proactive thermal management.

From Data Collection to Actionable Insight

Your smart sensors collect a massive amount of real-time data. This data, however, is just raw numbers until you process it. The IoT system creates a clear path from data collection to a useful instruction for your team. This automation is a key benefit of Industry 4.0.

The process is simple. The sensors gather data continuously. They transmit this information securely to a central cloud platform. Leading platforms you might use for this include Amazon Web Services (AWS) IoT Core, Microsoft Azure IoT Hub, or Google Cloud IoT Core.

Once in the cloud, data analytics software sifts through the information. It looks for anything out of the ordinary. When the system detects a potential problem, it does not just store the data. It generates a specific maintenance alert for your team. While the system sends alerts for general "maintenance needs," this process turns complex data into a simple, actionable task. You get data-driven insights that tell your technicians exactly what to check, transforming your smart factories.

The Power of AI and Machine Learning

This is where the "predictive" part of predictive maintenance truly comes alive. Artificial Intelligence (AI) and machine learning are the brains of the operation. They analyze the real-time data from your IoT sensors. This goes far beyond simple alerts for when a machine is too hot or vibrating too much. This level of automation is a leap forward for Industry 4.0.

Machine learning models learn the unique operational signature of a "healthy" machine. They use advanced pattern recognition to understand what normal looks like. Then, they use anomaly detection to spot tiny, subtle changes that signal a future failure. These systems can often identify early indicators 60-90 days before a breakdown. This learning process allows the system to tell the difference between normal operational wear and a critical problem.

Specific machine learning models are very effective for this task. Algorithms like Random Forest and AdaBoost show high accuracy. XGBoost is another powerful tool. It not only has high prediction accuracy but is also very efficient.

| Algorithm | Prediction Accuracy | Average Prediction Time (ms) |

|---|---|---|

| XGBoost | High | 232.6 |

| SVM | Lower | 401.1 |

As you can see, XGBoost delivers better accuracy in less time. This efficiency means you get faster, more reliable predictions. This powerful automation helps you fix problems before they stop your production line, boosting your overall efficiency. The IoT and Industry 4.0 framework makes this advanced predictive power possible.

Key Business Benefits of Predictive Maintenance

Adopting a predictive maintenance strategy does more than just prevent breakdowns. It fundamentally transforms your operations, delivering measurable improvements to your bottom line. This Industry 4.0 approach uses IoT automation to turn your equipment data into a powerful business advantage. For smart factories in the apparel industry, these benefits directly address the biggest challenges: downtime, costs, and quality control.

Maximize Uptime and Productivity

Unplanned downtime is the biggest enemy of productivity. Every minute a sewing line is stopped, you lose money. This is not just about the cost of a single repair.

"I have a building that's running. There's lights, there's power, there's internet, there's land costs, there's the cost of not getting stuff out the door. All of these different costs add up when a line is stopped." — Mohsin, Manufacturing Expert

Your factory's Overall Equipment Effectiveness (OEE) measures its true productive potential. In the textile industry, OEE often sits between 50-70% due to frequent changes and quality control stops. You can significantly boost this number. IoT technology gives you the real-time monitoring tools to see problems instantly and respond before they create a bottleneck. This automation helps you use real-time data to keep production moving smoothly.

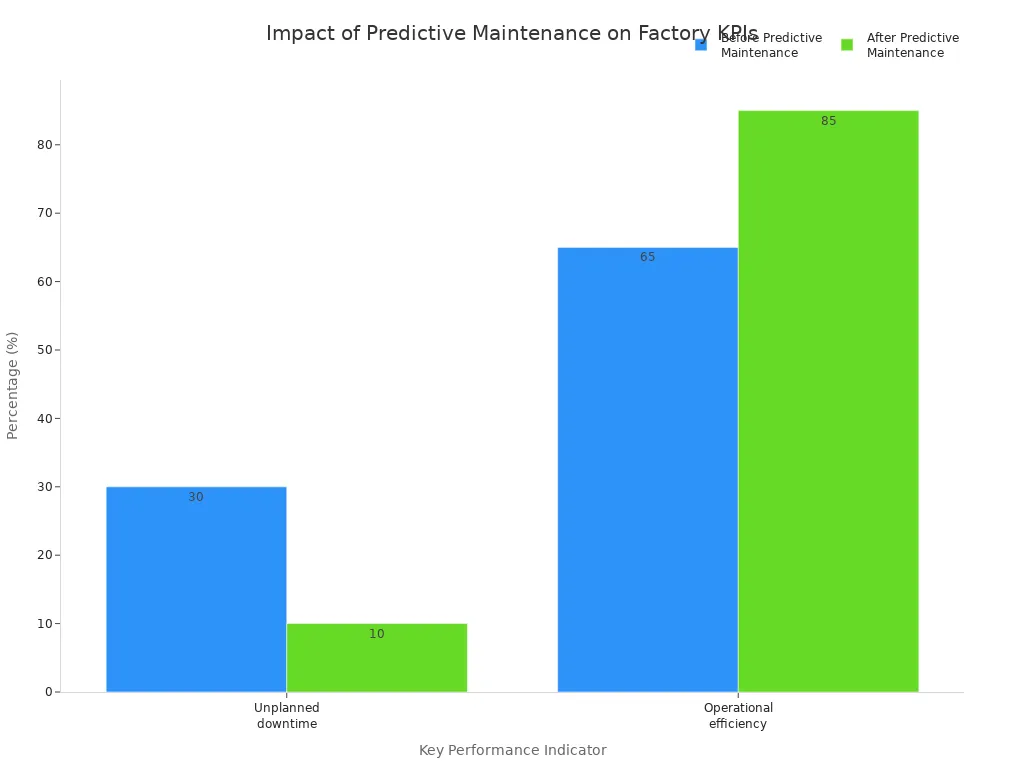

By using sensors to anticipate failures, you can schedule repairs during planned breaks. This proactive approach keeps your lines running during peak production hours. The results are dramatic. Factories see unplanned downtime drop from 30% to just 10%, while overall operational efficiency climbs from 65% to 85%.

Reduce Overall Maintenance Costs

Predictive maintenance helps you control your budget by eliminating guesswork. Instead of fixing machines on a rigid schedule they may not need, you perform maintenance exactly when required. This data-driven strategy can reduce your overall maintenance costs by 25% to 40%. You achieve these savings in two key areas:

- Optimized Labor: Your technicians stop wasting time on unnecessary inspections or reacting to emergencies. With predictive alerts from IoT sensors, they know which machine needs attention and why. This allows for dynamic maintenance scheduling, reducing overtime and letting your team focus on high-value tasks. This automation makes your entire team more effective.

- Just-in-Time Parts: You no longer need to keep a large, expensive inventory of spare parts on hand. The predictive system gives you advance warning of a potential part failure. This allows you to order the necessary component just in time for the scheduled repair, freeing up capital and reducing storage costs.

This Industry 4.0 method transforms your maintenance spending from a reactive expense into a predictable, optimized investment. The real-time data from IoT sensors ensures every dollar is spent effectively.

Enhance Stitch Quality and Machine Lifespan

Your product quality is directly linked to the health of your machines. A sewing machine that vibrates excessively or runs too hot cannot produce consistent, high-quality stitches. These subtle issues often degrade quality control long before a machine breaks down completely.

- Vibration sensors detect tiny instabilities that can cause skipped stitches or uneven seams.

- Thermal sensors warn you if a motor is overheating due to friction, which affects machine speed and stitch consistency.

With real-time IoT data, you can correct these problems before they impact your final product. This focus on optimal machine condition is a powerful form of automated quality control.

Furthermore, this predictive approach extends the life of your valuable equipment. By addressing small mechanical issues early, you prevent them from causing major damage. This reduces wear and tear, pushing back the need for expensive replacements. Predictive maintenance not only protects your brand's reputation for quality but also maximizes the return on your capital investments. This is a core principle of Industry 4.0: using data to make assets last longer and perform better.

A Practical Guide to Implementation

Transitioning to predictive maintenance is a clear, step-by-step process. This Industry 4.0 upgrade uses IoT automation to boost your factory's efficiency. You can start this journey by focusing on four key areas.

Step 1: Assess Critical Machinery

First, you must identify which machines are most important to your production line. You cannot monitor everything at once. Focus on the equipment where failure causes the biggest problems.

Consider these factors for each machine:

- Impact on Production: Does a failure create a major bottleneck?

- Product Quality: Can a problem with the machine ruin your products?

- Safety: Does the machine pose a risk to your operators?

- Maintenance Costs: Is the machine expensive or slow to repair?

A formal method like a Failure Mode and Effects Analysis (FMEA) can help you rank your equipment. This initial assessment is a vital first step in your Industry 4.0 implementation.

Step 2: Select and Install IoT Hardware

After you identify your critical machines, you need to give them a voice. You do this by selecting and installing IoT hardware. These smart sensors are the eyes and ears of your predictive maintenance system. You will attach sensors to key components to gather real-time data. This IoT network provides the constant stream of information needed for accurate predictions.

Step 3: Integrate a Data Analytics Platform

The IoT sensors generate a lot of raw data. A data analytics platform turns this information into useful insights. This software is the brain of your Industry 4.0 operation. It uses powerful automation to analyze the real-time data.

Platforms like Microsoft Fabric or INSIA.ai offer pre-built predictive models. This means you do not need to be a data scientist to get started. These tools connect to your IoT sensors and look for patterns that signal a future problem.

This integration turns complex real-time data into simple, actionable alerts, making advanced automation accessible.

Step 4: Train Your Team on New Protocols

Technology alone does not guarantee success. Your team must learn how to use these new IoT tools. Effective training is essential for this Industry 4.0 shift. Your technicians need to understand what the real-time alerts from the sensors mean. The goal is to translate technical data into clear maintenance tasks.

A great way to build skills is with a hands-on approach.

- I do: An expert shows your team how the IoT system works.

- We do: Your team works with the expert to solve real problems.

- You do: Your team confidently uses the predictive system on its own.

This method ensures your staff can use the new automation to improve efficiency.

Predictive maintenance is a strategic necessity in modern manufacturing. This Industry 4.0 approach uses IoT automation to boost your efficiency. You can achieve real results: less downtime, lower costs, and better quality. The predictive segment already holds over 32% of the AI in Textile market. This Industry 4.0 shift is happening now.

The data shows a clear trend:

- Nearly 70% of mills use IoT condition monitoring.

- Investment in this predictive technology is growing by almost 30% annually.

Your first step is to assess your current maintenance. Explore how IoT, real-time data from sensors, and this powerful automation can protect your equipment and give you a competitive edge. This Industry 4.0 use of real-time IoT data from sensors is the future. This real-time IoT automation is Industry 4.0.

FAQ

What is the initial investment for predictive maintenance? 💰

Your initial costs will vary. You must budget for IoT sensors and a subscription to a data analytics platform. The total investment depends on the number of machines you decide to monitor. Many find the long-term savings on repairs and downtime outweigh the upfront cost.

Do I need to hire data scientists?

No, you do not need to hire data scientists. Modern predictive maintenance platforms are designed for factory teams. They use simple dashboards and send clear alerts.

Your maintenance technicians can easily use these tools. The software does the complex data analysis for you.

How quickly can I see a return on investment (ROI)?

You can see benefits very quickly. Many factories report positive changes within the first few months. Early wins often include:

- Fewer unexpected machine stops.

- Better planning for maintenance tasks.

- A reduction in emergency repair costs.

Can I use predictive maintenance on older sewing machines?

Yes, you can. You can add modern IoT sensors to most older, or legacy, machines. This process is called retrofitting. It allows you to get valuable real-time data from your existing equipment without needing to buy all new machinery.

See Also

AI-Powered Predictive Maintenance Revolutionizing Textile Manufacturing by 2025

Leveraging Predictive Models for Future Success in Fashion Retail 2025

Machine Learning: Unlocking Fashion Trends and Driving Significant Sales Growth

AI Sensors Will Transform the 2025 Fashion Supply Chain Landscape

Achieving Perfect Balance: Predictive Analytics for Fashion Supply and Demand