Why SKU Proliferation Can Hurt Your Bottom Line

SKU proliferation drives up costs and adds layers of complexity to your business. Many businesses focus on growth but overlook the hidden expenses that come with higher SKU counts. You may see more choices, but each SKU carries extra inventory and handling costs. Poor SKU management can drain profits and slow operations. Rationalization lets you cut waste, boost efficiency, and improve your bottom line. When you focus on rationalization, you simplify processes and keep your business competitive. With careful rationalization, you can manage your SKUs better and spend less.

SKU Proliferation Explained

What Is an SKU?

You use an SKU to identify each product or product variation in your inventory. An SKU acts as a unique code that helps you track stock, manage orders, and organize your warehouse. You can assign an SKU to every item, whether it is a different color, size, or material. This system lets you know exactly what you have on hand and what you need to reorder.

- An SKU is a unique identifier for each product or variation.

- You use SKUs to tell products apart, even if they only differ by one feature.

- SKUs help your staff, suppliers, and systems stay on the same page.

- You can assign SKUs to services or warranties, not just physical items.

- Each SKU code is unique to your business and can include letters and numbers.

- SKUs are not the same as barcodes or serial numbers.

- You create your own SKU codes to fit your needs.

- SKUs play a key role in inventory management, production planning, and performance tracking.

When you use SKUs well, you keep your inventory organized and your business running smoothly.

How SKU Proliferation Happens

SKU proliferation starts when you add more and more SKUs to your inventory. You might want to offer new colors, sizes, or features to attract customers. Sometimes, you add SKUs to match competitors or respond to special requests. Over time, your product list grows, and you end up with many SKUs that do not sell well.

SKU proliferation can happen for several reasons:

- You expand your product line to reach new markets.

- You respond to customer feedback by adding new variations.

- You keep old SKUs even when sales drop.

- You create special SKUs for promotions or limited-time offers.

If you do not control SKU proliferation, you face higher costs and more complexity. Too many SKUs make it hard to manage inventory, fill orders, and keep your warehouse organized. You need to watch your SKU count and make sure every SKU adds value to your business.

Hidden Costs of SKU Proliferation

Inventory and Storage Costs

When you add more SKUs to your product lineup, your inventory grows. Each new SKU takes up space in your warehouse. You need to store, track, and manage every item, even if it sells slowly. Bloated portfolios often lead to higher storage costs because you must keep more products on hand. You may also need to rent extra space or invest in larger facilities.

A large number of SKUs increases the risk of slow-moving inventory. These items tie up your cash and can become obsolete. You might have to discount or write off unsold products, which hurts your bottom line. Managing a bloated portfolio means you spend more on insurance, utilities, and security for your warehouse. These hidden inefficiencies add up quickly and reduce your profits.

Tip: Regularly review your SKU list to identify products that do not sell well. Removing underperforming SKUs can free up space and lower your storage costs.

Operational Inefficiency

Every new SKU adds steps to your daily operations. You must update your systems, train your staff, and adjust your processes for each product. This extra work slows down your team and increases labor costs. When you have too many SKUs, your staff spends more time searching for products, picking orders, and handling returns.

- Overfilled warehouses make it harder to locate and package items.

- A large variety of SKUs can cause confusion, leading to mistakes like shipping the wrong product.

- These errors increase operational costs and delay order fulfillment.

You lose operational efficiencies when your team struggles to manage a complex SKU list. The total impact of SKU proliferation includes longer lead times and more errors. These problems can frustrate your customers and damage your reputation.

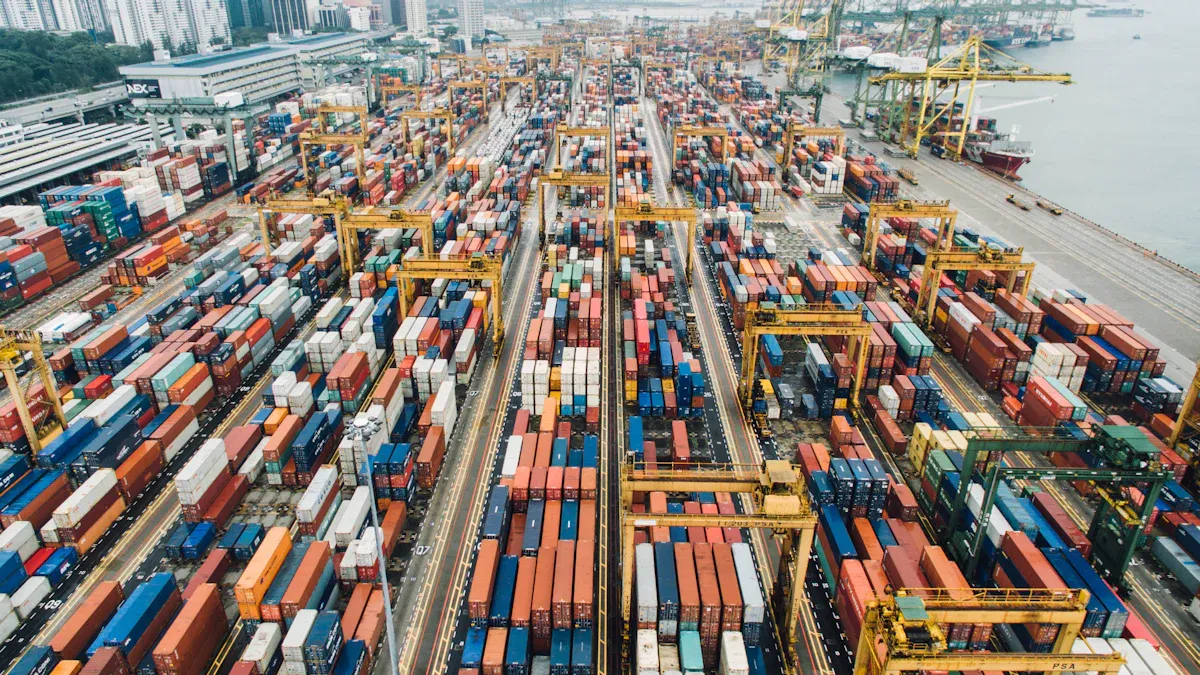

Supply Chain Challenges

Managing a high number of SKUs complicates your supply chain. You must coordinate with more suppliers, track more shipments, and handle more purchase orders. Production complexity rises as you try to source materials and schedule manufacturing for each SKU. Bloated portfolios make it harder to forecast demand and plan inventory levels.

When you have too many SKUs, your supply chain becomes less flexible. Delays and shortages become more common. You may run out of popular items while overstocking products that do not sell. This imbalance increases your costs and makes it harder to meet customer expectations.

Note: SKU rationalization helps you streamline your supply chain. By focusing on your best-selling products, you can improve order accuracy and reduce lead times.

Impact on Sales and Brand

Offering too many SKUs can confuse your customers. Studies show that when you present shoppers with too many choices, they feel overwhelmed. This choice overload makes it harder for them to decide, which can lead to lower sales and reduced satisfaction. Research by Van Ewijk and others confirms that excessive SKU proliferation weakens brand loyalty, especially when customers feel uncertain.

Chernev and colleagues found that a bloated portfolio can dilute your brand identity. Customers may struggle to understand what your business stands for if you offer too many similar products. Berger’s research shows that increasing product variety can change how people see your brand, sometimes causing confusion or a weaker brand image.

If you want to build a strong brand, you need to avoid overwhelming your customers. Focus on a clear, well-curated product lineup. This approach helps you stand out in the market and keeps your customers loyal.

Benefits of Product Rationalization

Cost Savings

You can unlock significant cost savings when you focus on rationalization. By reducing the number of SKUs, you cut down on storage expenses and lower your carrying costs. Fewer SKUs mean less money tied up in slow-moving inventory. You spend less on insurance, utilities, and warehouse labor. Rationalization also helps you avoid overproduction and excess stock, which leads to less waste and fewer markdowns. When you streamline your product lineup, you improve cash flow and free up resources for other business needs. This approach supports inventory reduction and helps you keep your operations lean.

When you remove underperforming SKUs, you see immediate savings in both space and money. This simple step can have a big impact on your bottom line.

Better Inventory Management

Rationalization makes inventory management much easier. You can track products more accurately and reduce the risk of errors. With fewer SKUs, your team spends less time searching for items and more time on value-added tasks. This leads to better organization in your warehouse and faster order fulfillment. Inventory optimization becomes possible because you can focus on stocking the right products in the right quantities. You avoid stockouts and reduce the chance of obsolete items piling up. Rationalization gives you better control over your inventory and helps you respond quickly to changes in demand.

Focus on Top SKUs

Most businesses find that a small number of SKUs generate the majority of their profits. This is known as the 80/20 rule: 20% of your SKUs often account for 80% of your sales. Rationalization lets you identify and prioritize these top performers. You can allocate more resources to your best-selling products and ensure they are always available for your customers. By focusing on your core SKUs, you simplify your supply chain and improve your ability to forecast demand. This targeted approach leads to higher margins and stronger business growth.

- Identify your top SKUs using sales data.

- Invest in marketing and inventory for your best sellers.

- Reduce or eliminate SKUs that do not contribute to your profits.

Improved Customer Experience

Streamlined product assortments create a better shopping experience for your customers. When you offer a clear selection of high-turnover SKUs, you reduce confusion and make it easier for shoppers to find what they need. Customers appreciate reliable product availability and quick service. Rationalization helps you avoid stockouts and ensures that your shelves stay organized. Using data-driven strategies, you can tailor your assortment to match customer preferences. This approach increases satisfaction and keeps shoppers coming back.

A focused SKU lineup not only boosts efficiency but also builds trust with your customers. They know they can count on you for the products they want.

Rationalization delivers benefits across your entire business. You save money, improve inventory management, and strengthen your brand. By focusing on the right SKUs, you create a more efficient operation and a better experience for your customers.

Demand-Driven SKU Rationalization Steps

Analyze SKU Performance

Start your demand-driven sku rationalization by looking closely at sku performance. Use sku analysis to review sales, turnover rates, and profitability for each item. You need to see which products move quickly and which ones sit on shelves. Sku analysis helps you spot trends and understand what your customers want. When you focus on sku performance, you can make better decisions about your product lineup. Use your ERP system to gather sku analysis data and track changes over time. This step forms the foundation of effective rationalization.

Set Rationalization Criteria

Next, set clear rules for rationalization. Decide what makes an SKU worth keeping. You might look at sales volume, profit margin, or customer demand. Sku analysis gives you the facts you need. Demand-driven sku rationalization works best when you use data, not guesses. Make a list of underperforming skus that do not meet your standards. This step keeps your sku management process objective and fair.

Tip: Use a table to compare sku performance side by side. This makes it easier to spot which SKUs need rationalization.

Streamline Product Lineup

Now, use demand-driven sku rationalization to remove products that do not add value. Focus on your best sellers and cut out the rest. Rationalization helps you reduce clutter and improve efficiency. Sku analysis shows you which items to keep and which to drop. When you streamline your lineup, you lower costs and make your business stronger. Demand-driven sku rationalization ensures you only keep SKUs that support your goals.

Monitor and Adjust

Rationalization is not a one-time task. Keep using demand-driven sku rationalization to review your lineup regularly. Track sku performance and repeat sku analysis to catch changes in demand. Use your ERP system to help with ongoing monitoring. Adjust your product mix as needed. This approach keeps your business agile and ready for new opportunities.

Stay proactive with demand-driven sku rationalization. Regular reviews help you avoid costly mistakes and keep your business on track.

Unchecked SKU proliferation can drain profits and slow your business. You face higher costs, more errors, and less focus on business growth. Rationalization gives you control. You use rationalization to cut waste and boost efficiency. Rationalization helps you streamline operations and improve customer satisfaction. With rationalization, you support business goals and keep your team focused. Rationalization also strengthens your brand. Make rationalization a regular part of your process. Start rationalization now to protect your business and drive results.

FAQ

What is SKU rationalization?

SKU rationalization means you review your product list and remove items that do not sell well. You focus on your best products. This process helps you save money and keep your business efficient.

How often should you review your SKUs?

You should review your SKUs at least once a year. Some businesses check every quarter. Regular reviews help you spot slow-moving products and keep your inventory fresh.

Can reducing SKUs hurt your sales?

Reducing SKUs rarely hurts sales if you keep your top performers. Most customers buy your best-selling items. Removing low-demand products lets you focus on what matters most.

What tools help with SKU management?

You can use ERP systems, inventory management software, and sales reports. These tools track product performance and help you make smart decisions about your SKUs.