Technology and Supply Chain Execution Efficiency Explained

Technology is changing supply chain efficiency at an unprecedented pace. Recent statistics show that early adopters of digital solutions see dramatic results:

| Metric / Impact Area | Statistic / Insight | Impact Aspect |

|---|---|---|

| Logistics cost reduction | 15% reduction in logistics costs by early adopters of AI-powered inventory management | Cost-effectiveness |

| Embedded AI and analytics adoption | 75% of supply chain management app vendors expected to deliver embedded AI by 2026 | Speed, Accuracy |

| Adoption of intralogistics robots | About 75% of enterprises expected to adopt smart robots by 2026 | Speed, Cost-effectiveness |

Digital tools boost supply chain efficiency by providing real-time data, improving accuracy, and reducing costs. However, digital transformation brings challenges such as integration complexity and workforce adaptation. Every organization faces unique obstacles, but those who embrace digital innovation achieve greater supply chain efficiency and resilience.

Technology’s Impact on Supply Chain Efficiency

Speed and Accuracy

Technology drives rapid improvements in supply chain efficiency by automating tasks and reducing manual errors. Companies use artificial intelligence, automation, and data analytics to streamline operations. These tools help organizations respond quickly to disruptions and adapt to changing market demands. For example, digital supply chain platforms allow teams to track shipments and inventory in real time. This immediate access to data supports faster decision-making and reduces delays.

Digital transformation of supply chains has enabled industries like healthcare and food to restructure their operations. Blockchain technology increases traceability, which improves accuracy and builds trust. Machine learning models that include collaboration and information sharing have shown a 6.34% increase in prediction accuracy. This leads to better operational efficiency and more reliable outcomes.

Organizations that adopt supply chain technology report significant gains. Exception handling time drops by up to 70% with AI-powered pattern detection. Forecasting errors decrease by nearly 87% when using deep learning algorithms. Automation of manual tasks speeds up workflows and reduces the risk of human error. These advances enhance supply chain efficiency and support greater agility.

Companies that invest in digital supply chain solutions see measurable improvements in speed, accuracy, and customer satisfaction.

Real-Time Data

Real-time data is a cornerstone of modern supply chain management. Edge computing processes data close to its source, which minimizes delays and enables quick responses. This approach improves operational efficiency by allowing teams to act on current information. Real-time tracking provides immediate visibility into shipment locations and inventory levels. Teams can forecast delays and adjust plans before problems arise.

- Edge computing reduces latency and bandwidth use, making data available even in low-bandwidth environments.

- Real-time analytics support smarter decisions by providing up-to-date insights.

- Integrated communication tools keep teams synchronized, reducing errors and improving efficiency.

- Centralized platforms unify data from inspections, freight, and customs, breaking down silos and offering a complete view of the supply chain.

Digital supply chain systems use IoT sensors and automation to collect and analyze data continuously. This enhances supply chain efficiency by enabling proactive planning and dynamic inventory management. Combining human inspection data with automated systems increases accuracy and timeliness. These improvements help organizations enhance supply chain efficiency and maintain a competitive edge.

Cost Reduction

Supply chain technology delivers substantial cost savings across operations. Companies that implement automation and digital solutions report reductions in labor costs, processing times, and inventory carrying costs. For example, robotic process automation (RPA) can cut supply chain costs by 30% to over 70%. Automation increases productivity by around 40%, while manual processes often result in up to 15% higher costs.

| Cost Saving Aspect | Reported Savings / Improvement Range | Example / Detail |

|---|---|---|

| RPA cost savings | 30% to over 70% | Companies using RPA in supply chain operations |

| Labor cost reduction | Up to 30% | Automation compared to manual processes |

| Productivity increase | Around 40% | Typical result of supply chain automation |

| Processing time reduction | From 4 hours to 2 minutes | Schneider Electric's RPA implementation |

| Inventory carrying costs | 15% to 25% reduction | Achieved through advanced forecasting and inventory classification |

| Transportation costs | Around 5% annual savings | Deere & Company via logistics optimization |

| Warehouse picking time | Up to 55% reduction | Strategic warehouse layout design |

| Shipping time | 92% reduction | Warehouse management system implementation |

| Delivery errors | 40% to 50% reduction | Automated systems and pick-to-light technologies |

Digital supply chain technology also improves sustainability. AI-powered route optimization reduces fuel consumption and carbon emissions. Companies see a 15% to 40% reduction in overall supply chain costs when they adopt comprehensive digital strategies. These savings allow organizations to reinvest in innovation and further enhance supply chain efficiency.

The digital transformation of supply chains not only cuts costs but also boosts supply chain resilience and sustainability, ensuring long-term success.

Defining Supply Chain Execution Efficiency

Key Metrics

Supply chain execution efficiency depends on clear, measurable indicators. Companies use these metrics to track progress and identify areas for improvement in supply chain management. The most common key performance indicators include:

- On-Time Delivery (OTD): Measures the percentage of orders delivered on or before the promised date. This shows how reliable the supply chain is.

- Total Order Cycle Time (TOCT): Tracks the average time from order placement to delivery. Shorter cycle times reflect faster processes.

- Order-to-Cash Cycle Time (O2C): Calculates the time needed to turn orders into cash. This metric highlights financial efficiency.

- Routing Compliance: Checks if shipments follow planned routes and schedules. High compliance means better delivery timing and cost control.

- Freight Cost Per Unit Shipped: Measures transportation cost efficiency for each unit. Lower costs help companies stay competitive.

- Inventory to Sales Ratio: Compares inventory levels to sales. This ratio helps companies manage stock and avoid overstocking.

- Perfect Order Delivery Rate: Shows the percentage of orders delivered without errors. High rates indicate strong supply chain management.

Companies that monitor these metrics can quickly spot problems and make changes to boost supply chain efficiency.

Process Integration

Process integration plays a vital role in supply chain management. It connects different departments and partners, creating a seamless flow of information and goods. Internal integration aligns practices within a company, while external integration links suppliers and customers. Together, these efforts break down silos and improve supply chain efficiency.

- Process integration standardizes and connects activities across the supply chain.

- It improves communication and collaboration, leading to faster and more accurate decisions.

- Better coordination reduces lead times, stockouts, and excess inventory.

- Real-time data sharing helps teams respond quickly to changes or disruptions.

- Open communication systems support smooth information flow and reduce mistakes.

When companies integrate their processes, they achieve higher operational efficiency and stronger supply chain management. This approach leads to smoother operations and better results for everyone involved.

Technologies Enhancing Efficiency

Artificial Intelligence

Artificial intelligence stands at the forefront of digital supply chain transformation. Companies use this technology to analyze large amounts of data and make better decisions. AI improves warehouse efficiency by planning routes for workers and robots, balancing inventory, and reducing operational costs. It automates repetitive tasks, detects errors early, and enables predictive maintenance. AI also supports accurate demand forecasting, which helps avoid stockouts and excess inventory. By using digital twins and simulations, organizations can test scenarios and optimize operations without disrupting real-world processes. This advanced technology increases transparency and safety across the supply chain.

IoT and Sensors

IoT and sensors play a key role in digital supply chain visibility. These devices track shipments, vehicles, and inventory in real time, providing precise location and condition updates. Sensors monitor temperature and humidity, ensuring sensitive goods remain safe during transport. IoT automates inventory tracking, reducing human error and improving efficiency. Real-time data from sensors supports predictive maintenance, minimizing downtime. Logistics teams use this technology to respond quickly to disruptions and improve customer satisfaction. IoT also enables data sharing among partners, promoting collaboration and proactive decision-making.

Automation

Automation and robotics transform digital supply chain operations by increasing speed and accuracy. Robotics handle picking, packing, and sorting in warehouses, reducing manual errors and labor costs. Autonomous mobile robots and automated guided vehicles streamline workflows and eliminate repetitive tasks. Automation of supply chain operations allows staff to focus on higher-level decisions. Companies like Amazon and Walmart use these technologies to achieve faster and more accurate order fulfillment. Automation also optimizes delivery routes and automates documentation, supporting agile and resilient supply chains.

Blockchain

Blockchain technology brings transparency and trust to digital supply chain networks. It records every transaction on a decentralized, tamper-evident ledger, making data accessible to all authorized participants. This technology tracks products from origin to delivery, ensuring traceability and reducing counterfeiting. Smart contracts automate procurement and payment processes, reducing paperwork and errors. Blockchain strengthens security and enables quick identification of issues, such as recalls. Industries like food and pharmaceuticals benefit from improved compliance and product quality.

Cloud Computing

Cloud computing supports real-time collaboration and data sharing in digital supply chain management. It provides instant access to data from warehouses, transport, and distribution centers. Cloud platforms unify information from different departments, enabling efficient workflows and better analytics. Teams can monitor performance metrics and shipment locations from anywhere, supporting remote work and multisite operations. Cloud-based solutions improve demand forecasting, stock planning, and risk management. Customers benefit from order tracking, which increases satisfaction and loyalty.

Digital supply chain technology, powered by AI, IoT, automation, blockchain, and cloud computing, delivers greater efficiency, visibility, and resilience for modern organizations.

Enhanced Efficiency in Action

Inventory Management

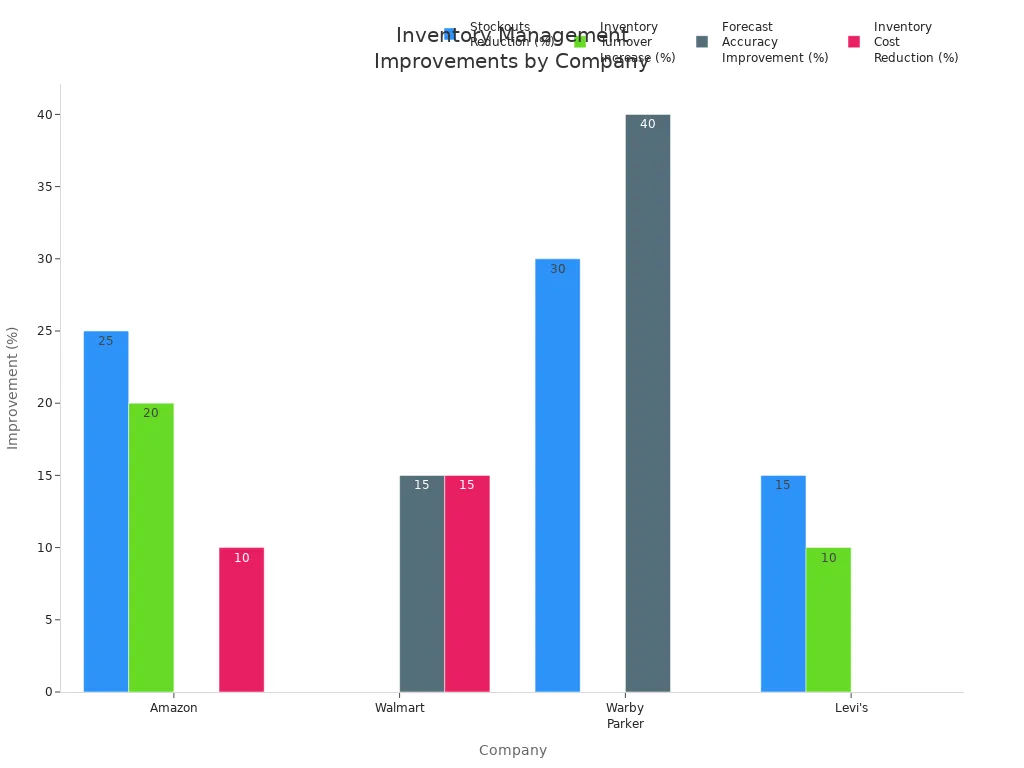

Companies now use advanced technology to achieve enhanced efficiency in inventory management. Artificial intelligence and big data analytics help predict demand and reduce stockouts. For example, Amazon uses AI-driven predictive inventory systems. This approach led to a 25% reduction in stockouts and a 20% increase in inventory turnover. Walmart integrates weather and social media data into its forecasting, which resulted in a 10-15% reduction in inventory costs. Warby Parker and Levi's also use AI to improve forecast accuracy and respond faster to changes in demand.

| Company | Technology Adopted | Key Improvements | Metrics / Outcomes |

|---|---|---|---|

| Amazon | AI-driven predictive inventory | Reduced stockouts, improved forecast accuracy, optimized inventory turnover | 25% reduction in stockouts, 20% increase in inventory turnover, 10% reduction in carrying costs |

| Walmart | AI forecasting with external data | Integrated weather, social media, events data for demand forecasting | 10-15% reduction in inventory costs, 5-7% increase in sales, 15% improvement in forecast accuracy |

| Warby Parker | AI-powered omnichannel inventory | Fine-grained demand prediction, real-time data analysis, reduced stockouts | Up to 30% reduction in stockouts, 25% reduction in overstocking, 40% improvement in forecast accuracy |

| Levi's | AI demand forecasting | Dynamic, evolving forecasting model | 15% reduction in stockouts, 10% increase in inventory turnover |

N-iX worked with a Fortune 500 company to create a unified cloud platform, connecting over 100 data sources. This upgrade improved data management and enabled predictive analytics. Another project with a German engineering company improved logistics for more than 400 warehouses using computer vision and natural language processing.

Warehousing

Warehousing operations have seen enhanced efficiency through the adoption of automation in logistics. Automated Guided Vehicles (AGVs), Automated Storage and Retrieval Systems (ASRS), and robotic packing systems now handle many tasks that once required manual labor. These technologies reduce errors and speed up order fulfillment. Advanced Warehouse Management Systems (WMS) and IoT sensors provide real-time tracking and precise inventory records. Artificial intelligence and machine learning help predict demand and optimize resource allocation. These improvements allow warehouses to adapt quickly to changes in the market and maintain high accuracy.

| Technology Category | Impact on Efficiency and Accuracy |

|---|---|

| Robotic Packing Systems | Automate packing with precision, reduce manual labor and errors, speed up fulfillment processes. |

| Automated Storage and Retrieval Systems (ASRS) | Optimize space utilization, accelerate retrieval, reduce errors in picking and storage. |

| Goods-to-person and Pick-to-light Systems | Minimize manual sorting and picking time, increase productivity and accuracy. |

| RFID and Advanced Barcode Scanning | Enable real-time, accurate inventory tracking, improve inventory visibility and control, reduce stock errors. |

| Advanced Warehouse Management Systems (WMS) | Provide precise inventory records, optimize order processing, enhance omnichannel connectivity and accuracy. |

| Internet of Things (IoT) Solutions | Offer real-time data on inventory and environment, enable predictive management, reduce downtime, improve control. |

| Artificial Intelligence (AI) and Machine Learning (ML) | Use predictive analytics for demand forecasting, optimize resource allocation, reduce waste and errors. |

| Augmented Reality (AR) and Virtual Reality (VR) | Improve training, order picking accuracy, and maintenance through immersive and assisted technologies. |

Last-Mile Delivery

Last-mile delivery is a key area for enhanced efficiency in logistics. Companies use several technological solutions to improve performance:

- Route optimization software and real-time tracking systems help drivers deliver packages faster and more accurately.

- Electronic proof of delivery (ePOD) increases customer satisfaction by confirming successful deliveries.

- Artificial intelligence and machine learning support predictive delivery scheduling and better route planning.

- IoT devices provide live tracking dashboards and delivery analytics.

- Electric vehicles and autonomous vehicles lower costs and reduce environmental impact.

- Smart lockers allow customers to pick up parcels at convenient locations, reducing failed deliveries.

- Drone deliveries are being tested to speed up service in rural and crowded urban areas.

These solutions help logistics providers meet rising customer expectations and improve productivity.

Benefits of Technology Adoption

Visibility and Collaboration

Digital transformation brings end-to-end visibility to supply chains. Cloud platforms, IoT sensors, and blockchain connect every part of the network. These tools break down silos and allow real-time data sharing. Stakeholders can track shipments, monitor inventory, and access updates instantly. This level of visibility supports faster, smarter decisions and reduces the risk of errors.

- Centralized control enables accurate forecasting and better planning.

- Automation reduces manual mistakes and improves efficiency.

- Collaboration tools help suppliers, manufacturers, and retailers work together.

- Digital systems provide transparency and traceability, building trust among partners.

Real-time end-to-end visibility and collaboration lead to a more responsive and competitive supply chain ecosystem.

Customer Satisfaction

Technology improves customer satisfaction by making supply chains more reliable and transparent. Real-time tracking and digital communication keep customers informed about their orders. Automated route planning and fleet management ensure timely deliveries. These improvements reduce delays and errors, leading to higher service quality.

Customers benefit from greater transparency and traceability. They can see where their products are at any moment. This visibility builds confidence and loyalty. Companies that use digital solutions often see higher customer ratings and repeat business.

Enhanced visibility and digital tools help companies meet customer expectations and deliver consistent service.

Scalability

Digital technology allows supply chains to scale quickly and efficiently. Artificial intelligence and machine learning support predictive analytics and demand forecasting. IoT devices collect real-time data, helping companies adjust to market changes. Cloud computing offers flexible infrastructure for global operations.

| Technology | Role in Scaling Supply Chains | Example/Application |

|---|---|---|

| AI & Machine Learning | Predictive analytics, automation, scenario planning | Target, Amazon |

| IoT | Real-time data collection and sharing | Smart devices, sensors |

| Cloud Computing | Scalable, flexible infrastructure | ASOS, global retailers |

| Advanced Analytics | Predictive and prescriptive insights | Domino’s, logistics optimization |

| Blockchain | Transparency and traceability | Digital supply chain networks |

Digital infrastructure supports end-to-end visibility, transparency and traceability, and rapid response to disruptions. Companies can expand or adapt their operations without losing control or efficiency.

Overcoming Challenges

Cybersecurity

Technology-enabled supply chains face a growing wave of cyber threats. Attackers target weak links, such as third-party vendors, to access sensitive data and disrupt operations. Since 2018, supply chain cyberattacks have surged by more than 2,600%, impacting over 54 million victims in 2023. Financial losses now average $82 million per year for affected organizations in industries like healthcare and energy. By 2025, nearly half of all companies worldwide may experience attacks on their software supply chains.

Common threats include:

- Phishing and social engineering targeting vendor credentials.

- Exploitation of unpatched software vulnerabilities.

- Weak access controls and misconfigured systems.

- Risks from counterfeit hardware or compromised software from suppliers.

High-profile incidents, such as the MOVEit and SolarWinds attacks, show how attackers exploit trust relationships and software vulnerabilities. Companies must strengthen access controls, patch systems regularly, and monitor third-party risks to protect their supply chains.

Proactive cybersecurity measures and regular risk assessments help organizations defend against evolving threats.

Integration

Integrating new technologies with legacy supply chain systems presents technical and organizational challenges. Many companies struggle with complex data formats, employee resistance, and the risk of disrupting daily operations. Successful integration improves visibility, reduces errors, and streamlines workflows.

Best practices for integration include:

- Conducting thorough assessments of existing systems and defining clear goals.

- Choosing the right integration approach, such as middleware, APIs, or cloud-based solutions.

- Using canonical data models to enable communication between old and new systems.

- Implementing gradual change management to ease transitions and build acceptance.

A step-by-step approach, supported by strong collaboration between internal teams and external partners, ensures smoother integration and long-term efficiency.

Workforce Adaptation

Adopting new supply chain technologies requires employees to learn new skills and adapt to changing workflows. Companies like Amazon have shown that investing in both advanced technology and comprehensive training leads to significant gains in productivity and cost savings.

Effective strategies for workforce adaptation include:

- Providing targeted training programs based on skill assessments and feedback.

- Offering transition support through peer mentors and digital learning platforms.

- Promoting a culture of continuous learning and open communication.

- Recognizing and rewarding employee efforts during the transition.

Organizations that balance automation with human expertise create flexible, resilient teams ready for future challenges.

Ongoing training and clear communication empower employees to embrace change and drive supply chain success.

Steps to Enhance Supply Chain Efficiency

Assess Readiness

Organizations must first assess their readiness before they can enhance supply chain efficiency. This process starts with a careful evaluation of technology infrastructure, data quality, and system integration. Leaders should also review talent, process maturity, and organizational culture. Strategic factors such as AI governance, compliance, and scalability play a key role. Teams identify gaps in skills, processes, and technology. A readiness report helps analyze current capabilities and highlights areas for improvement. Companies should also consider the value proposition, market acceptance, resource maturity, and regulatory risks. This approach ensures that digital solutions align with business needs and supply chain management goals.

- Evaluate technology, data, and system integration.

- Assess talent, process maturity, and culture.

- Review AI governance, compliance, and scalability.

- Identify gaps in skills, processes, and infrastructure.

- Analyze value proposition and market acceptance.

- Address regulatory and resource risks.

- Develop a readiness report with recommendations.

Build a Roadmap

A clear roadmap guides organizations as they enhance supply chain efficiency. Leaders align technology initiatives with the overall strategy. They assess current capabilities and identify gaps in software and processes. Data quality and integration receive special attention. Teams introduce digital improvements in phases to avoid disruption. Cross-functional collaboration ensures a holistic solution. Companies focus on continuous progress, not just rapid change. Partnering with experienced providers can support a smooth transformation.

- Align technology with supply chain strategy.

- Assess current capabilities and identify gaps.

- Ensure data quality and integration.

- Plan phased digital implementation.

- Collaborate across departments.

- Focus on steady improvement.

- Partner with experts for robust solutions.

Measure Results

Measuring results is essential to enhance supply chain efficiency. Organizations select a few key metrics to track progress. These include on-time shipping rate, backorder rate, order cycle time, inventory days on hand, rate of return, and order picking accuracy. Advanced digital tools such as predictive analytics and automation help monitor these metrics. Continuous improvement processes use these insights to optimize supply chain management.

| KPI Name | Description |

|---|---|

| On-time shipping rate | Percentage of items shipped on time |

| Backorder rate | Orders not fulfilled immediately |

| Order cycle time | Time from order to delivery |

| Inventory days on hand | Days to sell inventory |

| Rate of return | Percentage of items returned |

| Order picking accuracy | Percentage of orders picked correctly |

Focusing on a few relevant KPIs and using digital tools helps organizations benchmark performance and drive ongoing improvement.

Technology transforms supply chain execution by increasing speed, accuracy, and cost savings. Key advancements include AI, robotics, IoT, and cloud computing. These tools drive real-time visibility, automation, and better decision-making.

- Over 60% of organizations expect robotic process automation to reshape supply chains by 2025.

- Autonomous robot deployment grew by 320% from 2022 to 2024.

Companies that embrace innovation gain agility and resilience. Leaders should evaluate their current processes and invest in digital upgrades to stay competitive.

FAQ

What is supply chain execution efficiency?

Supply chain execution efficiency measures how well a company completes tasks like shipping, warehousing, and inventory management. High efficiency means faster deliveries, fewer mistakes, and lower costs.

How does technology improve supply chain visibility?

Technology uses tools like IoT sensors and cloud platforms to track goods in real time. Teams can see where products are, monitor conditions, and respond quickly to problems.

Which technology offers the biggest impact on cost savings?

Automation often delivers the largest cost savings. Robots and software handle repetitive tasks, reduce labor costs, and speed up processes. Companies also save money by cutting errors and waste.

What challenges do companies face when adopting new supply chain technology?

Companies face issues such as cybersecurity risks, system integration problems, and workforce training needs. Careful planning and ongoing support help overcome these barriers.

Can small businesses benefit from digital supply chain solutions?

Yes, small businesses gain from digital tools. Cloud-based systems and automation help them compete with larger companies by improving speed, accuracy, and customer service.

See Also

Key Features That Differentiate WarpDriven ERP For Smart Enterprises

How Outsourcing Supply Chain Management Accelerates Business Growth

New EDI Tracking Technologies Enhancing Modern Shipment Transparency

Top Three Methods Lean Logistics Improves Supply Chain Sustainability

Strategies To Secure Long-Term Success In B2B Order Fulfillment