How Warehouse Operations Benefit from SOPs in 2025

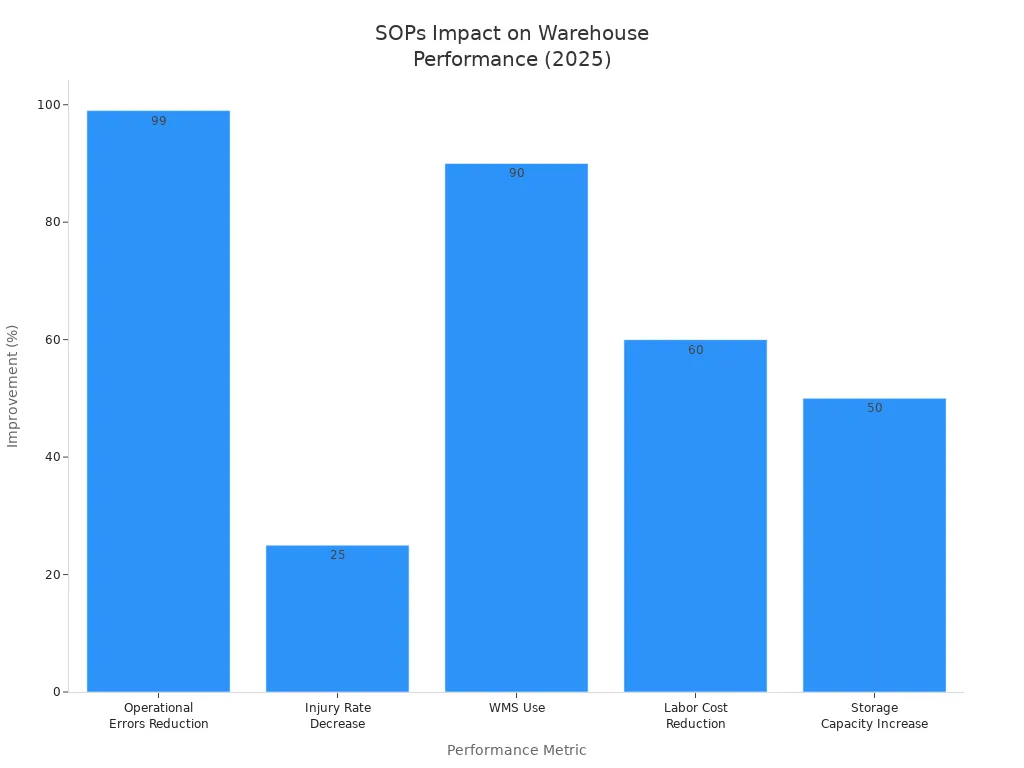

Standard operating procedures now transform warehouse operations in 2025, setting new benchmarks for accuracy and speed. You see immediate benefits: improved efficiency, fewer mistakes, and safer workplaces. The latest data shows a 99% reduction in operational errors and a 25% drop in injuries in highly automated warehouses.

Comprehensive SOPs bring clear instructions, standardized tasks, and strong safety protocols across all warehouse processes. They help you keep quality high, reduce variability, and create predictable outcomes—even as technology and staff change. Consider how adopting or updating your SOPs can solve common warehouse challenges and keep your operations ahead.

SOPs and Warehouse Operations

Standard Operating Procedures Defined

You rely on standard operating procedures to keep your warehouse running smoothly. These procedures are detailed, written instructions that guide you and your team through every step of warehouse operations. They cover everything from receiving shipments to picking, packing, and shipping orders. When you follow warehouse standard operating procedures, you make sure each process happens the same way every time. This consistency helps you deliver quality service, meet safety standards, and avoid costly mistakes.

- SOPs in warehouse management are documented procedures that tell you how to perform tasks safely and correctly.

- These procedures help you:

- Keep processes consistent and repeatable.

- Train new staff quickly and effectively.

- Lower risks by following safety steps.

- Check and improve how you work.

- Stay compliant with laws and quality rules.

- A good SOP includes your company name, a clear title, control numbers, the purpose, scope, responsibilities, and step-by-step instructions.

- When you use warehouse standard operating procedures, you onboard staff faster, reduce errors, save money, and keep your workplace safe.

If you skip or ignore these procedures, you risk poor quality, low productivity, miscommunication, and more accidents.

Why SOPs Matter in 2025

In 2025, warehouse operations face new challenges and higher expectations. You need to move goods faster, keep workers safe, and meet strict regulations. Warehouse standard operating procedures help you reach these goals. Leading companies like Walmart, UPS, and DHL use SOPs to boost safety and productivity. You see fewer injuries because safety checklists cover PPE, equipment use, and emergency plans. Regular training and clear instructions keep everyone prepared.

Tip: Use digital SOP platforms to make procedures easy to access and update. This helps your team follow the right steps every time.

Modern SOPs use automation, sensors, and data analytics. You get real-time updates and can adjust quickly to changes. This technology makes your warehouse more efficient and adaptable than ever before. When you follow warehouse standard operating procedures, you improve efficiency, reduce errors, and keep your team motivated. You also protect your business from fines and disruptions by staying compliant with safety and quality standards.

| Challenge | Impact on Operations | Solution |

|---|---|---|

| Inadequate Staffing | Delays, errors, safety hazards | Training, automation, temporary staff |

| Safety Hazards | Injuries, damaged goods | Safety training, PPE, equipment checks |

| Inefficient Technology | Lower efficiency, higher costs | Upgrade systems, use automation, regular reviews |

Warehouse standard operating procedures give you the structure you need to handle these challenges and keep your warehouse operations running at their best.

Improving Warehouse Efficiency

Streamlining Key Processes

You can streamline warehouse processes by using clear and well-defined SOPs. These procedures help you standardize every step, from receiving goods to shipping orders. When you document and follow SOPs, you reduce confusion and make sure everyone knows what to do. This leads to faster and more reliable warehouse operations.

Research shows that organizations with strong SOPs outperform others by 31%. You save time on administrative tasks and reduce costly mistakes. SOPs also make it easier to train new staff, so you spend less time explaining tasks and more time getting work done. When you combine SOPs with technology like Warehouse Management Systems, barcode scanning, and RFID, you boost accuracy and speed. These tools help you track inventory, automate routine tasks, and keep your workflows running smoothly.

Note: 82% of warehouses have invested in technology to support SOPs, showing the importance of combining digital tools with standardized processes.

Here are some strategies you can use to streamline warehouse processes:

- Document and standardize key procedures such as receiving, picking, and dispatch.

- Use scalable Warehouse Management Systems to automate tasks and improve inventory management.

- Implement lean warehousing principles to remove unnecessary steps.

- Cross-train staff to increase flexibility and reduce bottlenecks.

- Monitor real-time data and key performance indicators (KPIs) to make quick decisions.

- Set up exception handling protocols to keep operations running even when problems arise.

You will see measurable improvements in your warehouse, such as higher inventory accuracy and shorter order cycle times. These changes help you achieve timely and accurate order fulfillment.

| Measurable Improvement | Description |

|---|---|

| Inventory Accuracy Rate | Percentage of inventory items accurately recorded compared to physical count |

| Order Picking Accuracy | Percentage of orders picked without errors or discrepancies |

| Perfect Order Rate | Percentage of orders fulfilled without any errors including correct items, quantities, and timing |

| Order Cycle Time | Time taken from order placement to fulfillment |

| Inbound Throughput | Rate at which incoming goods are received, inspected, and stored |

Reducing Errors and Waste

SOPs play a key role in reducing errors and waste in your warehouse. When you follow standardized procedures, you make fewer mistakes during picking, packing, and shipping. This leads to fewer returns, less damaged inventory, and lower costs.

After adopting SOPs, many warehouses report a 25% increase in inventory accuracy and a 25% reduction in inventory carrying costs. You also see a 20% improvement in order fulfillment rates. These numbers show how SOPs help you cut down on waste and improve operational efficiency.

You can minimize inventory discrepancies and prevent stockouts by:

- Ensuring uniformity in inventory tasks across teams.

- Using SOPs as training manuals for quick onboarding and correct execution.

- Maintaining compliance with industry regulations for traceability and quality control.

- Standardizing processes like order picking, stock audits, and replenishment.

- Incorporating technology such as barcode scanning and automated reorder alerts for real-time monitoring.

When you use SOPs, you maintain accurate stock levels and keep your warehouse inventory management reliable. This helps you avoid costly mistakes and keeps your customers satisfied.

Enhancing Safety and Training

Safety is a top priority in warehouse operations. SOPs give you clear, step-by-step instructions that help prevent accidents and keep your team safe. You reduce risks by following safety protocols for equipment use, chemical handling, and emergency response.

Common warehouse incidents include slips, trips, falls, forklift accidents, and manual lifting injuries. SOPs address these risks by:

- Requiring certified operators and regular equipment inspections.

- Keeping aisles clear and stacking loads safely.

- Providing ergonomic training and using mechanical aids.

- Enforcing proper storage and hazard communication for chemicals.

- Conducting regular safety audits and emergency drills.

Tip: Regular training and clear SOPs help new employees learn quickly and follow safety rules from day one.

SOPs also make training more effective. You give new hires comprehensive guides, so they understand their tasks and safety responsibilities. Uniform training ensures everyone follows the same safety protocols, which boosts productivity and reduces accidents. When you use SOPs, you create a safer, more productive warehouse environment and support continuous improvement in your operations.

Comprehensive Warehouse SOPs

Essential Components

Comprehensive warehouse SOPs give you a strong foundation for every process in your facility. You need clear, step-by-step instructions for tasks like picking, packing, and shipping. These instructions help your team avoid confusion and keep operations smooth. Define roles and responsibilities so everyone knows their duties. Safety protocols must align with OSHA standards to protect your staff and meet legal requirements.

You should include these key elements in your warehouse standard operating procedures:

- Step-by-step instructions for each process, such as receiving, inventory management, and shipping.

- Defined roles and responsibilities for every team member.

- Safety protocols and compliance guidelines.

- Explanations for why each process matters.

- Regular reviews and updates to keep SOPs current.

- Annual audits and reassessments after major changes or incidents.

- Integration of technology like Warehouse Management Systems, barcode scanners, and RFID.

A table can help you organize these components:

| Component | Purpose |

|---|---|

| Step-by-step instructions | Ensure consistency and reduce errors |

| Roles and responsibilities | Clarify duties and accountability |

| Safety protocols | Protect staff and meet regulations |

| Technology integration | Improve accuracy and efficiency |

| Regular reviews | Keep SOPs relevant and effective |

Best Practices for SOP Development

When you develop and implement warehouse SOPs, you set your team up for success. Start by defining the scope and goals for each procedure. Use templates to save time and keep documents consistent. Write instructions in clear, simple language. Add visuals like diagrams or screenshots to help your team understand each step.

Follow these steps to develop and implement warehouse SOPs:

- Define the purpose and scope for each SOP.

- Document procedures with detailed, easy-to-follow steps.

- Assign roles for authors, reviewers, and approvers.

- Train employees using hands-on methods or digital tools.

- Involve staff in the creation and review process.

- Use electronic data management systems for easy access and updates.

- Review and update SOPs at least once a year or after major changes.

Tip: Involve your team when you create or update SOPs. Their feedback improves accuracy and boosts morale.

By following these best practices, you ensure your comprehensive warehouse SOPs stay clear, accessible, and effective. This approach helps you maintain high standards in every process, from inventory management to shipping.

Technology and SOP Implementation

Digital Tools for SOPs

You now have access to powerful digital tools that make creating, sharing, and updating SOPs easier than ever. In the past, you might have relied on handwritten notes or printed manuals. Today, you use AI-powered platforms that help you write, edit, and organize standard operating procedures quickly. These tools let you work with your team in real time, so everyone always sees the latest version.

- Cloud-based platforms allow you to edit SOPs together, track changes, and control who can view or update each document.

- AI helps you build SOPs by analyzing best practices and existing documents, making sure your instructions stay accurate and up to date.

- Digital SOPs can include videos, images, and step-by-step guides, which help your team learn faster.

- You can connect SOPs to training systems, so employees always know when something changes.

- Mobile access and QR codes let your staff check procedures on the warehouse floor, reducing mistakes and speeding up onboarding.

With these digital tools, you keep your SOPs current and relevant. You also make training easier. New hires can learn at their own pace, using interactive guides and short videos. This approach reduces training time and helps your team remember important steps. You see fewer errors and faster fulfillment as a result.

Automation and Integration

Implementing SOPs becomes much smoother when you combine them with automation and a warehouse management system. Automation lets you handle repetitive tasks like picking, packing, and inventory tracking with machines and software. This reduces human error and keeps your processes consistent.

When you integrate SOPs with your warehouse management system, you get real-time data and analytics. You can monitor every step, spot problems early, and make quick adjustments. Automation also improves safety by taking over heavy lifting and repetitive jobs, which lowers the risk of injuries.

- Real-time monitoring helps you follow SOPs and fix issues fast.

- Automated systems track inventory and orders, making fulfillment more accurate.

- You can scale your warehouse operations as your business grows, without major changes.

- Automation reduces labor costs and lets your team focus on higher-value tasks.

- Data from automated systems helps you find bottlenecks and improve your workflows.

By automating processes and integrating SOPs with technology, you create a warehouse that runs smoothly, safely, and efficiently. You deliver better fulfillment, reduce costs, and keep your team engaged.

Continuous Improvement

Reviewing and Updating SOPs

You operate in a warehouse environment that changes quickly. New technology, updated regulations, and shifting customer needs all impact your daily operations. To keep your procedures effective, you must review and update your SOPs regularly. Most experts recommend reviewing SOPs at least once a year or whenever you introduce significant changes, such as new equipment or process updates.

- Regular reviews ensure your SOPs stay relevant and reflect current best practices.

- You maintain operational effectiveness by adapting procedures to new conditions.

- Documenting each review and update helps you meet compliance requirements and keeps your records organized.

Warehousing remains a dynamic field. If you treat your SOPs as living documents, you can respond quickly to changes and avoid falling behind. You should always incorporate SOPs into new employee training to ensure everyone follows the same standards from day one.

Tip: Schedule annual SOP audits and involve frontline workers in testing new procedures. Their feedback ensures practicality and effectiveness.

Employee Feedback and Training

Your team plays a vital role in SOP compliance and continuous improvement. When you develop and implement warehouse SOPs, you should involve employees at every stage. Their insights help you identify gaps, improve clarity, and boost acceptance.

Ongoing training is essential for maintaining high standards. Comprehensive safety programs that focus on equipment use, hazard recognition, and emergency protocols have reduced workplace injuries by 50% over three years. You see even better results when you use a mix of workshops, hands-on practice, and digital learning modules.

- Certification on equipment and regular refresher courses keep skills sharp.

- Learning Management Systems and SOP management software make training accessible and track progress.

- Interactive tools like quizzes and gamification increase engagement and retention.

You foster a culture of continuous improvement by encouraging feedback and recognizing employees who excel in SOP compliance. Well-trained staff adapt quickly to changes, reduce errors, and help your warehouse run smoothly. When you prioritize ongoing training and feedback, you support long-term success for your SOPs and your entire operation.

You gain measurable benefits from strong SOPs in your warehouse. These include improved workplace safety, higher productivity, and better training for your team. You also see greater efficiency with automation and digital tools.

- Clear safety protocols and regular reviews reduce accidents.

- Standardized processes and WMS integration boost operational efficiency and accuracy.

- Ongoing staff training and employee involvement drive productivity and continuous improvement.

Take time to review and update your SOPs. This step keeps your warehouse competitive and ready for future challenges.

FAQ

What is the main purpose of warehouse SOPs?

You use warehouse SOPs to create clear, step-by-step instructions for every task. These procedures help you keep operations consistent, safe, and efficient. SOPs also make training easier and reduce mistakes.

How often should you update warehouse SOPs?

You should review and update your SOPs at least once a year. Update them sooner if you add new technology, change processes, or notice recurring problems. Regular updates keep your procedures effective and compliant.

Can digital SOPs replace paper manuals?

Yes, digital SOPs offer many advantages. You access them quickly, update them easily, and share them with your team in real time. Digital SOPs also support videos and images, which help you train staff faster.

How do SOPs improve warehouse safety?

SOPs give you clear safety steps for every task. You follow rules for equipment, storage, and emergency actions. This reduces accidents and keeps your team safe every day.

What role does employee feedback play in SOP development?

You gain valuable insights from your team. Their feedback helps you spot gaps, improve clarity, and make SOPs more practical. Involving employees increases buy-in and leads to better results.

See Also

How SaaS WMS Solutions Revolutionize Modern Warehouse Operations

Cutting-Edge Intralogistics Driving The Next Era Of Warehousing

Is Overflow Warehousing The Key To E-commerce Expansion?

Boosting Warehouse Efficiency Through Intelligent Ecommerce Tactics

Why Warehouse Audits Are Essential For Operational Efficiency